Plasterboard cabinets

The area of an apartment does not always satisfy the people living in it. This problem is especially relevant in large families. Purchased furniture does not always meet the needs of consumers for financial reasons, so it is often easier to make it yourself.

Pros and cons of drywall products

This material is quite cheap, while it is quite practical and comfortable. In skillful hands, a unique, beautiful product is obtained from it. Environmental damage, harm to health (release of toxins into the air, radioactivity) are completely excluded. Drywall retains heat well, allows you to install lighting fixtures; if desired, it can be painted or even covered with plaster.

The large dimensions of the sheets make it possible to make most of the blocks from one finished element. Therefore, cutting and joints will not reduce the stability of the cabinet and its mechanical properties too much. The positive aspects of this material are also excellent sound insulation, immunity to mold and other microscopic fungi.

If people suffering from allergies live in a house (apartment), then products from gypsum plasterboard are much more correct to use than chipboard.

Talking about the shortcomings is not entirely appropriate, because these are just the objective properties of the drywall sheet.

They should be taken into account in advance or refuse to use it altogether:

- the cabinet will have to be built-in and not moved;

- the place should be chosen immediately. The workpieces are formed and cut to size without errors, otherwise you just have to throw them away;

- since not all walls are with right angles, it will not be possible to prepare the components in advance;

- it is undesirable to store heavy, sharp and cutting objects in the cabinet (since it is not very durable).

The simplicity of cutting drywall makes it a very interesting construction material and allows you to create parts of almost unlimited complexity. By varying the thickness of the sheet, you can reduce or increase the safety margin of the structure. This means that even with the doors there should be no problems, and the furniture will calmly withstand the load they create.

It is advisable to choose workpieces with refractory impregnation for the kitchen.

Varieties

The partition-closet for things made of plasterboard turns out well, which cannot be said about furniture for storing heavier items. Swing or sliding doors must be made of glass, wood or MDF. Drywall itself is not at all suitable for this function. The wall-closet is attractive already because its sound insulation characteristics are higher than those of ordinary walls.

Having placed the storage of things on the entire wall, you can:

- take off the worry of decorating it;

- place everything that is required inside;

- free up other space as much as possible.

Considering the presence of drywall and frame, the dividing wall can be made extremely thin. The height of the rods and shelves is selected so that all clothes can hang or lie folded calmly, and also so that placing them inside or taking them out, if necessary, is easy and free.

It is easy to form not only partitions from plasterboard sheets, but also a variety of open shelving, sliding wardrobes and even full-fledged dressing rooms. It is convenient to put a TV set and various decorative items in a niche.Complementing it with spot lighting is also a good idea.

A plasterboard wardrobe can be equipped with traditional details (the same ones that are used in solid wood or MDF cabinet products):

- shelves;

- boxes;

- shoe sections;

- pantographs;

- barbells;

- elements for the rational storage of trousers or ties.

Often a cabinet made of gypsum plasterboard is designed to store household items. Then inside it is useful to provide a holder for an iron or ironing board, containers for household chemicals, as well as sections for various little things and dry food.

Bookcases from this material can also be made, but the shelves will need to be strengthened as much as possible, because they will have to endure serious loads.

Where are appropriate?

Drywall can be used almost anywhere, and imagination is the main constraint. It is easy for him to give any shape and embody the most daring design ideas. Quite often you can find a cabinet made of gypsum plasterboard with a niche, which allows you to both achieve elegance and increase the functionality of the product. Fireproof or water-resistant grades of the material allow it to be used everywhere, including bathrooms and kitchens, without fear of emergencies.

There is no ready-made niche in the hallway, and there is no storage room in the corridor? The case is fixable, cabinets based on gypsum board can be placed anywhere. The best place for them is the corner, since the support on the load-bearing wall increases the reliability of the furniture. In kitchens, a partition cabinet delimiting functional areas sometimes appears on one side as a bar counter. Such a solution cannot but be considered quite interesting.

If the cabinet stands in the bathroom, the problem of hiding the washing machine disappears, and at the same time it will be possible to install several shelves (by introducing wooden beams into the frame).

How to do it yourself?

Project development

Project development is an absolutely necessary thing. Without it, it is very easy to make a lot of mistakes, the correction of which will be extremely difficult. Be sure to draw up a drawing and mark the required dimensions on it, taking into account where the furniture will be originally delivered (since you cannot move it).

When calculating the dimensions, pay attention to the size of any compartment, to the height of the shelves and space for boxes, as well as to the points where suspension structures are provided.

Self-preparation of a sketch or the choice of a completely finished scheme is your own business.

The location of the structure being created is marked with plumb lines, building levels, painting cords, and so on. The maximum measurement accuracy is ensured by the laser level. He will also show what is the geometry of the base and a single corner. Want to do some auxiliary lighting? It is advisable to deal with wires before working with the frame.

It is important to remember that the individual parts indicated in the drawings and in the diagrams as single ones, in fact, turn out to be paired. Consider this when you calculate the need for materials and expenses.

Before starting the main work, remove the wallpaper (or other covering) from the walls and thoroughly clean them, level them to perfect smoothness.

Materials and tools

Fasteners for a drywall cabinet can be of five types:

- dowel-nails;

- anchor screws;

- butterflies;

- snails;

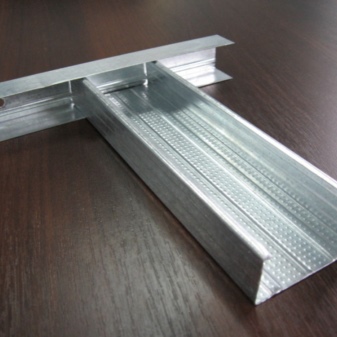

From the very beginning, decide whether you need a regular drywall sheet or its moisture-resistant variety. When choosing a metal profile, you should also figure out what kind of it you need - UD or CD. The corners protecting the sheet can be either plastic or metal. The profiles are attached to the sheets with self-tapping screws.

In addition to the listed materials, you will also need:

- painting net;

- composition for finishing putty;

- primer;

- decorative plaster, enamel or paint;

- fittings;

- lighting devices, switches, cables.

When choosing the roller version of the door, buy a complete set, rather than individual rollers.This will be both easier and significantly more reliable.

Of the tools for assembling a drywall cabinet you will need:

- puncher (can be replaced with a drill);

- screwdriver;

- Angle grinder;

- containers for the preparation of solutions;

- painting knife and measuring level;

- set of spatulas;

- plane for finishing edges;

- rulers and squares (to take small measurements).

Sanding of individual surfaces is done with sandpaper. Try to keep it ready. Responsible installers will definitely add a spirit level and a plumb line to this list, which are necessary for more effective control of verticals and planes.

Assembling the frame

The assembly of the frame begins with the formation of its skeleton. As a rule, metal is used, but where the cabinet is subjected to intense mechanical stress, it is worth choosing a wooden beam. The steel version is more correct to use, because it is much more convenient and practical for inexperienced builders.

Pay particular attention to its quality and degree of dryness. If it is not enough, immediately after the final drying, the destruction of the cabinet will begin. The markings will allow you to mount the guide profiles using dowel nails. Do not forget that all parts attached to the base must be glued with rubber insulation. Otherwise, the furniture will react to shrinkage or change its dimensions when the temperature changes. It is undesirable to deviate from the project, as this can lead to insufficient rigidity of the product.

Frame assembly sequence:

- transfer of the conceived structure from the drawing to the walls (at this stage, show maximum attention in order to avoid mistakes - they will interfere with the correct installation of drywall sheets);

- the use of shock-absorbing tapes (damping vibrations that prevent them from entering the structural elements of the cabinet);

- installation of guide profiles type UD. It is best to cut them to the desired length with metal scissors, and faster (but we recommend only experienced ones) - with a grinder;

- installation of rack fragments of profiles. They should go into the guides;

- interconnection of profiles.

The distance between the fasteners depends on the size of the product - the larger it is, the closer the profiles should be to each other, otherwise you can forget about strength.

Frame sheathing

Sheathing of frames does not differ from similar work during the installation of partitions. However, the areas that need to be strengthened are sheathed with a double layer (staggered). When deciding to place the cabinet in the bathroom, be sure to use green drywall (it is moisture resistant).

At the end of the sheathing, it is worthwhile to do the gluing of the joints and seams, gluing the perforated corners and filling the surface. At this, the rough manipulations with the future cabinet can be considered completed.

Most often, the frame is sheathed with plasterboard both inside and outside, but for a small cabinet, one external finish is enough. If you have already had to veneer gypsum plasterboard walls or ceilings, then no problems should arise during work.

The basic principles are as follows:

- for connection, self-tapping screws are used for screwing into metal with a diameter of 25 mm;

- the maximum gap between the attachment points is 20 cm;

- only after the block is attached along the perimeter, it makes sense to attach it in other places;

- it is undesirable to press the screws in more than a millimeter, so as not to break the cardboard;

- if the limiter does not work, the self-tapping screw must be removed and tightened again at least half a centimeter from the problem area (which is subject to reinforced filling);

- it is possible to simplify the processing and alignment of the seam if there is a gap of 0.2-0.3 cm between the sheets.

Finishing

People like the finish, of course, more than other types of work. It is during such work that you can see the final result live. It is customary to paint the interior of the furniture in the same color as the walls in order to visually expand the room.

It is recommended to glue the shelves with wallpaper or vinyl film, but before that, the surface must be primed. Doors can be made of laminated chipboard, tempered glass or a special mirror (the back of which is glued with a special coating). Drawings of nature, scenes from cartoons and so on are often applied to the doors.

The choice of a particular image is only your own business.

When creating a drywall cabinet, it is imperative to putty any hole where the screws were screwed, as well as the joints of the sheets (a painting net is glued to them in order to do everything as accurately as possible). The dried primary layer is sanded and primed, after which they look to see if it needs to be additionally puttyed (with repetition of sanding and priming). Only after that can we say that the preparation for the finishing is completed.

If the cabinet is to be used in a bathroom, the shelves and walls should be covered with ceramic tiles or mosaics. Do not forget to regularly check the evenness of the structure and the observance of vertical, horizontal lines in it throughout the work (even when "finishing touches" are being made).

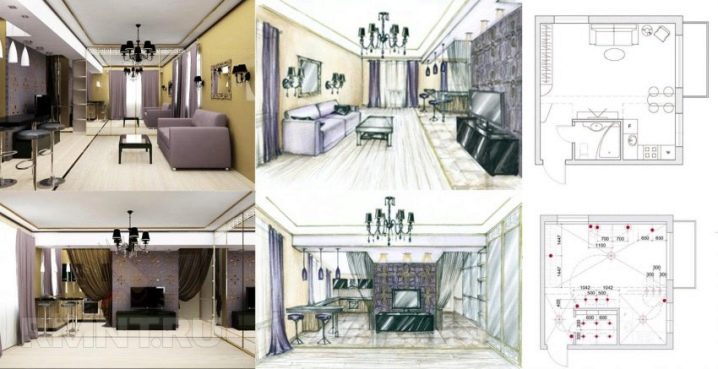

Beautiful models in interior design

The question may arise about the meaning of all these manipulations, because drywall is not traditionally perceived as a good and sound structural material. This opinion is fundamentally erroneous, since in fact it is quite possible to make from it not only durable and reliable, but also very attractive externally furniture.

Many models of beautiful drywall cabinets are equipped with LED spotlights, and hidden strips with the same LEDs are used unreasonably little, although they allow you to create very pleasant aesthetic effects. Designers recommend choosing multi-colored ribbons. Thus, the result will become even more interesting. Please note that finishing with tiles will not be possible if at the very beginning (when designing) you do not provide for the use of the most durable types of drywall and strong profiles.

Combines the aesthetic and practical advantages of a door with mirror inserts. They will allow you to beat almost any room design, visually expand it and help you save money on buying individual mirrors.

As for the configuration, making the plasterboard cabinet straight or angular is everyone's personal business. When you are not completely confident in your abilities, it is best to use the option with open shelves. Such furniture will allow you to store dishes and other utensils, bulk substances and all kinds of powders, jars and bags, which are so common in modern life. An interesting solution in many cases is pasting the surface with a film imitating the look of natural wood and even its texture: it is inexpensive and elegant at the same time.

As we can see, it is quite simple to build a cabinet based on gypsum board., this will allow you to save money, and not be limited to ready-made store solutions, and get a completely comfortable piece of furniture. If you still doubt the aesthetic merits of such a choice, know that it is drywall that is used by the leading designers of Russia and the world.

How to make drywall shelves in the bathroom is the next video.

The comment was sent successfully.