All About Screens

It is impossible to tell everything about screening screens, this information can fill the pages of a lengthy monograph. A roar is an installation operating in the coal and any other mining industry, in the construction industry (production of crushed stone, sand, cement), in beneficiation factories. The name is a general collective term for a variety of structures, united by the old name-characteristic according to the onomatopoeic principle.

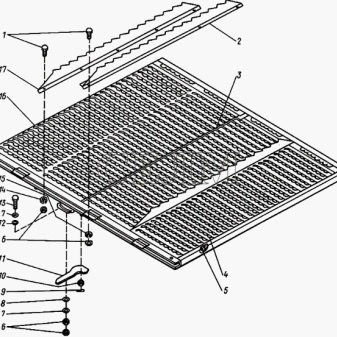

General description and purpose

The characteristic of a screen invariably begins with a mention of the variability of its design. The screening device can be primitive, designed for small volumes and rather complex aggregates, with high productivity. The differentiation of screens occurs according to different principles: the screening area (which determines the volume of the final product) and the intended purpose - from the separation of particles by size, solving specific problems and to sifting grain from litter and pebbles.

Screens for a screen are often identified with screens, but this is not entirely correct, since the mesh sheet is only a part of the structure, fixed in a frame of a certain shape. This unity, complemented by certain design features, is called a rumble, because it emits a characteristic noise during operation.

The size, shape of the holes and their diameter, the structure on which the screening process is carried out, its autonomy or participation in the process in parallel with other units (equipment for road construction, conveyor, crushing and screening devices) - these are factors that determine the purpose of the sieve and the type of mesh that most fully meets the goals set for the industry.

The area of application is determined not so much by the configuration of the frame as by the type of mesh.

-

Slotted are used for processing raw materials from paper, chemical and food industries. Significant advantages allow them to be installed in welded structures, traps and drums in sugar and paper mills.

-

The installation of a screen with a different number of levels from 1 to 5 or more allows sequentially, using vibration, to divide into fractions by size, sift from unnecessary inclusions and get rid of moisture.

-

There are dozens of mesh sizes that can be used in almost all industries. Workers have different tasks, which means using different materials and fractions.

The sieving surface, its features, formal features, which are being produced with increasing success by domestic manufacturers, are the main component of the efficiency of any process where a sieve is used. This design is divided into several common types. There are also lesser-known, custom-made for special needs. There are a number of unique gadgets.

Developments in this area are constantly being improved, innovative technologies and new, progressive materials are used.

Views

A sieve for screens is a general collective term, which means harp-shaped (self-cleaning), polyurethane (made of reinforced threads, with a special coating of modern material), rubber, string, woven, perforated and grate, trellis and many other options.The material of manufacture is very different: sheets of metal alloys, stainless or corrugated metal wire, spring steel, interwoven wire structures made of stainless steel, carbon steel or high carbon steel, pressure welded from a metal bar. Modern production with its potentialities and new developments allows it to maintain the required dimensions, without ignoring GOST with its requirements for the quality and endurance of the used material of manufacture.

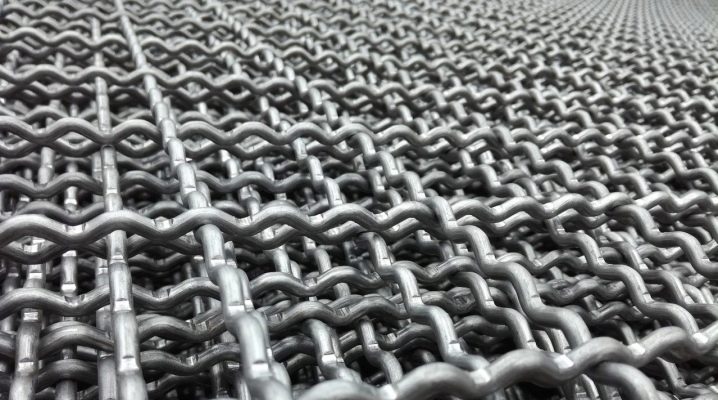

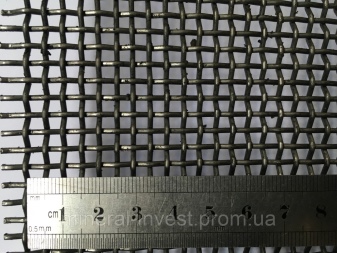

The mesh can be with partial, double or complex corrugation, made according to European standards. The characteristics of the material make the mesh targeted for drum, quiet or environmentally friendly recycling.

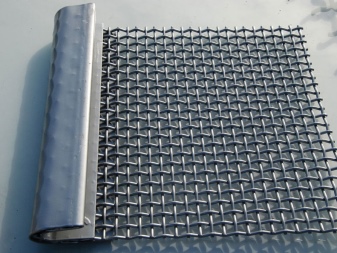

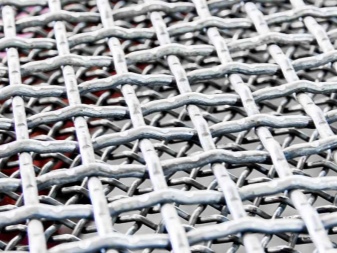

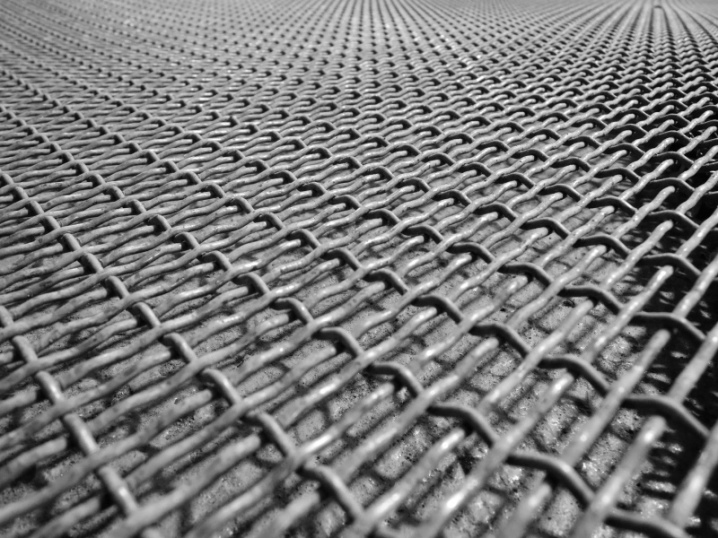

Wicker

Sometimes they mention their relative strength, inferior to products from special steels from advanced foreign manufacturers. but they have their own advantages that cannot be ignored - ease of repair (if necessary), low weight, democratic cost, a variety of product options offered on the market, - with different thicknesses of wire, made of stainless steel and carbon steel types, with the most whimsical ways of weaving.

Among the proposals from the manufacturer there is the possibility of exact execution of the design required by the customer. It means:

-

different cell shapes - slotted, in the form of a square or rectangle;

-

wire of different diameters;

-

wide size ranges for selection - from a millimeter and a quarter to 10 cm;

-

self-cleaning and even polyurethane dressing - for strength and flexibility of the required degree.

The name "braided" simply means that the common manufacturing method is the interlacing of wire strands, but there are a huge variety of types designed for universal or narrowly focused purposes. In some sources, you can find the name - woven sieves.

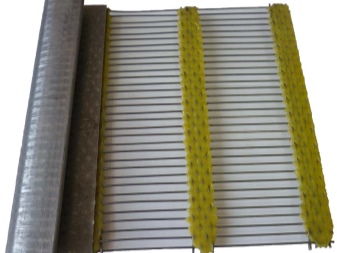

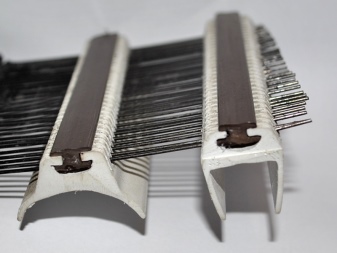

Strings

Common functional devices with a long history of use for everyday or utilitarian purposes: for sorting sand, coal or peat. Extremely simple in design - these are strings stretched over a frame made of spring steel or stainless steel. The gaps between the stretched strings are the same, there are no transverse or interwoven elements. Therefore, they are considered to have high productivity. Of the pleasant features, it is possible to note the ability to self-cleaning and low clogging.

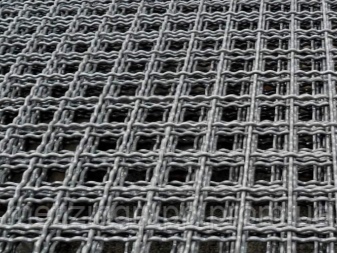

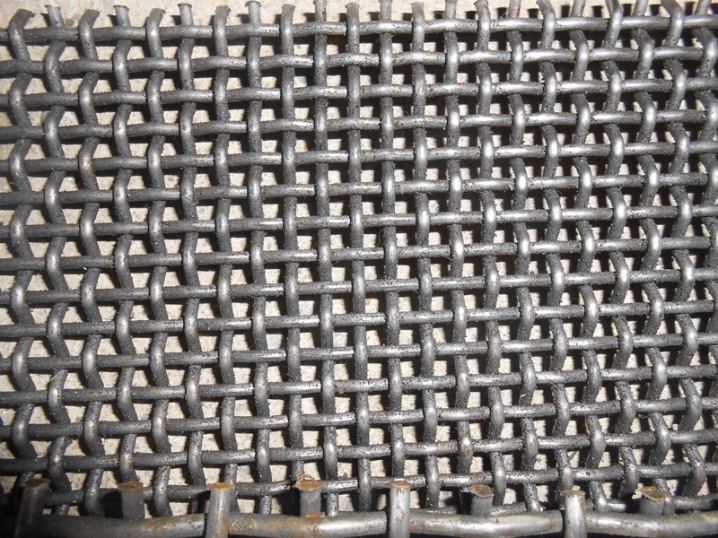

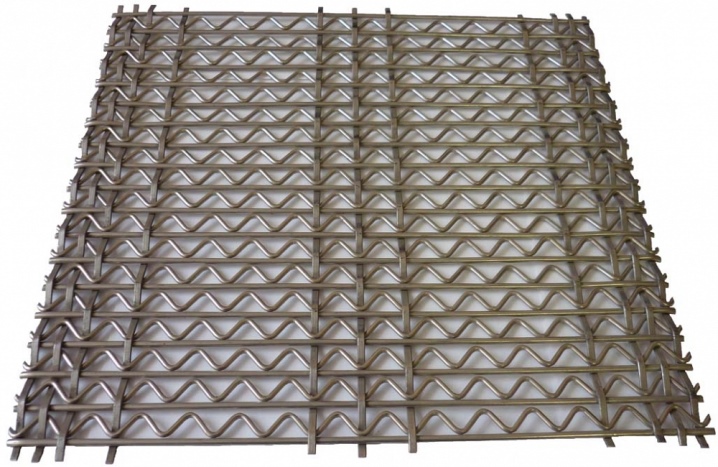

Welded

Not particularly popular. Among the shortcomings, a laborious manufacturing method is mentioned (welding of metal rods, hence the name, uneven distribution at the joints). They are inferior to wicker sieves in terms of springiness, which minimizes shock loads from coarse fractions. However, in some cases, it is advisable to use.

Finger-shaped

An interesting constructive solution, in which metal rods of various diameters are used, placed at different distances at the ends in cassettes. They are used for sifting dolomite, limestone and lumpy materials interspersed with clay. Usually placed in a cascade, the diameter of the sieve depends on the material for which it is used.

Woven

Name of sieves made by weaving from metal wire. There are common types, with maximum fractions or custom-made. Most often they are used for dispersing nonmetallic materials with fractions up to 150 mm.

In most cases, the name "woven" is used as a synonym for the name "wicker", so manufacturers in the price list write these two terms side by side.

Polymer

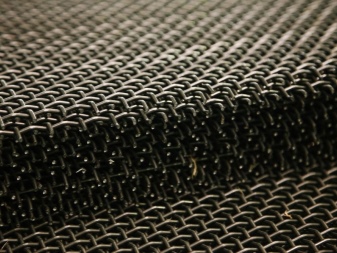

The second name is polyurethane. These are sieves, in the manufacture of which the achievements of industrial chemistry are used, - strong connections, lightweight and not subject to corrosion. The same term denotes sieves in which reinforced metal threads are coated with durable polyurethane. It is an irreplaceable thing in construction for sorting crushed stone, sand and gravel, expanded clay, but they are also used in the mining industry. A successful application is achieved due to the sectional structure of the structure.

Self-cleaning

The second name is harp-like. They are made of corrugated metal wire.

If it is necessary to work with sticky or clogging materials, stainless steel strings are taken, on which polyurethane or rubber dressings are placed.

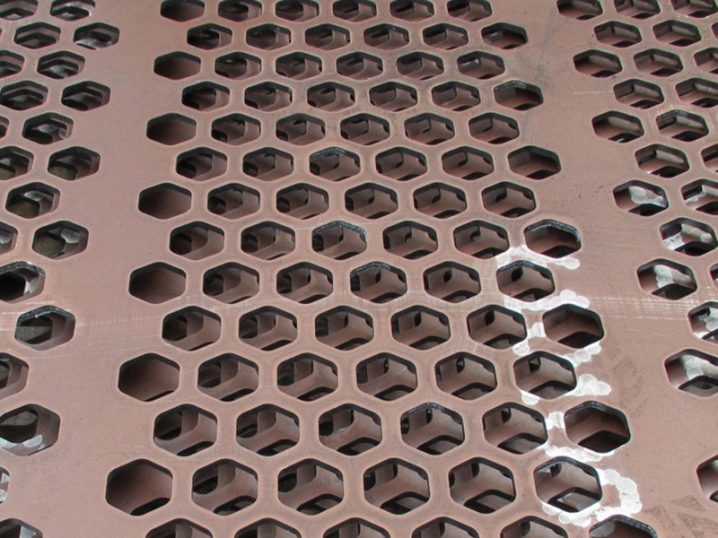

Perforated

Due to the peculiarities of the device (made of a single metal sheet with perforated holes), they have received a wide range of applications - from the food industry to animal husbandry, in the mining and mining industries. They differ not only in the diameter of the holes made, but also in the material of manufacture - from metal alloys to steel and aluminum. The shape, size of holes, type of alloy determine the choice of the consumer and the scope of application.

Selection Tips

Manufacturers advise to determine in advance the priorities, which, in turn, depend on the application. Of great importance is the purposefulness of the acquired device, its adaptability to the performance of certain functions, the processing of material. If you buy a high-end product, but not designed for loads for which it is not intended, you can only achieve a quick failure, and even the highest-quality manufacturing material will not help here. Often, only the advice of professional consultants helps you choose the right type from a wide range.

Cleaning features

Often included in the list of requirements that are checked for compliance when purchasing a screen for a screening machine. They depend not only on the type of device, but also on the characteristics of the processed raw materials. In this process, much depends on the operating conditions, prevention, respect, the strength of the fastening of the elements and the design of the screen for the screen. It should not be forgotten that the use of self-cleaning sieves is not possible in all industries due to their rather limited scope.

The comment was sent successfully.