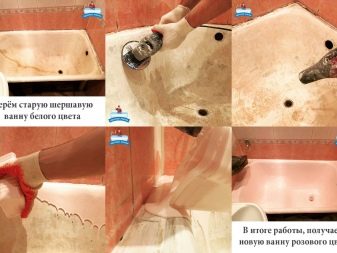

How to properly restore baths with liquid acrylic?

A bath in a modern apartment is one of those places that is used daily by all family members for the purpose of personal hygiene. The snow-white shine of this irreplaceable sanitary ware gives us a feeling of comfort, warmth, and most importantly - cleanliness. However, in the process of many years of regular use of the surfaces of any enamel or acrylic bathtubs, over time, they lose their original aesthetic and hygienic characteristics: their original white color changes, scuffs, chips, scratches, cracks, dents appear. The inner surface of the font, which previously had smoothness and shine, turns into rough and dull, it becomes more and more difficult to remove dirt, soap and lime deposits from it, and mold and pathogens develop in chips and cracks - a rather unpleasant sight.

Even so, all is not lost! Knowledgeable people believe that there is no need to rush to dismantle and throw away the old bathtub in order to buy a new one instead. You can restore the outer coating of this item at home and on your own. From an economic point of view, the cost of such a restoration of an old bath will cost you several times less than the cost of buying and installing a new hot tub.

Material features

To solve the problem of restoring a worn or damaged surface of cast iron and metal baths, the so-called liquid acrylic is used - a polymer material produced from acrylic and methacrylic acids with the addition of certain polymer components to their composition. Polymethyl acrylates have been produced by the chemical industry for over half a century, and they were originally created as the main compound for the production of organic glass. Today, various components are added to this composition, thanks to which the production of acrylic sanitary ware and cladding material has become possible. Acrylic materials today have firmly won their niche in the sales market and have gained increased popularity due to the fact that products made of them are very lightweight, durable in use and easy to process.

Restoring the inner surface of an old bathtub can be done in various ways., for example, with the use of special paints and varnishes, but the service life of such a restoration is not long. The most durable results during operation can be obtained if an old hot tub is repaired with liquid acrylic: this material has an increased adhesive ability to metal surfaces and cast iron bases, and also creates a durable working layer when applied, which has a thickness of 2 to 8 millimeters.

Using an acrylic compound, restoration work on the restoration of the bath surface can be carried out without fear of damaging the bathroom tiles. In the process of work, acrylic does not emit harmful components with a pungent odor into the atmosphere, it quickly polymerizes under the influence of air, and when working with this material, special devices and additional components are not needed. The finished acrylic composition contains a base and curing agents.The surface of the bath after processing it with liquid acrylic becomes resistant to mechanical and chemical influences, and most importantly, it has an anti-slip effect, which is its feature and distinctive feature in comparison with other materials.

Advantages and disadvantages

Renewal of an old bathtub with a liquid acrylic compound is becoming more and more popular among the population. This inexpensive material wins the love of consumers because its use provides an even and smooth coating that retains its original appearance for quite a long time. Any crack on the original surface is filled with liquid material and smoothed out. Acrylic polymer has the property of low heat conductivity, as a result of which water in a bathtub treated with this material retains its heat much longer than in a conventional enamelled hot tub.

People who use acrylic-coated bathtubs report that they feel much more comfortable in it: acrylic absorbs sound, and its surface retains heat and is smooth to the touch. Treating the surface of an old bathtub with an acrylic compound simplifies the further procedure for its care: you no longer need to use expensive and complex aggressive compounds for cleaning - you just need to wipe the bathtub surface with a cloth or sponge moistened with ordinary soapy detergent. Those who decided to restore the surface of the bathtub on their own at home using liquid acrylic, note that this restoration option has fully justified itself from an economic point of view and extended the service life of the sanitary ware for many years: from 10 to 15 years.

Modern acrylic compounds can be made in almost any color scheme. This can be done by adding tinting paste to the main acrylic composition when preparing the working solution. This is another advantage of the polymer material, which makes it easy to match the color of the updated bath with the overall design concept of your bathroom as a whole.

Before deciding to update your bathtub with liquid acrylic, it is necessary to take into account some of the disadvantages of the method.

- Despite the fact that the bath bowl itself does not need to be dismantled, all drainage devices will have to be removed at the time of restoration, and then, after completion of the work, reinstalled.

- If the bathroom bowl had initial factory defects, then, spreading over the surface, the acrylic composition will repeat their outlines.

- The time it takes to fully cure the material can be significant. Advertising information promises to consumers that after 36 hours the bath surface will be completely ready for use, although practice shows that, depending on the thickness of the layer, the curing of acrylic can take up to 96 hours, that is, four days.

- The result of the restoration largely depends on the quality of the material and the professionalism of the person who will carry out the entire volume of work. If during the restoration mistakes were made due to a violation of the process technology, the strength and solidity of the polymer coating can be very quickly destroyed.

- To accelerate the polymerization process, uninformed people use heating devices, which does not correspond to the process technology and damages the polymer bonds, destroying the strength of the resulting acrylic layer.

- Abnormally applied acrylic is very difficult to remove from the restored surface in order to correct mistakes and start over. This is due to the high adhesiveness of the material.

In the process of making an acrylic liquid mixture, some manufacturers may add components to its composition that, from their point of view, improve the quality of the material, but in practice it turns out that such additives do not lead to positive results at the end of the work.Therefore, to carry out restoration work, it is best to use proven and well-known brands of acrylic, whose manufacturers have a good reputation in the market for their products.

What's the best material?

Baths made of metal or cast iron, as a rule, are initially coated with enamel at the factory, therefore, if it is necessary to restore their internal surfaces, the question arises as to which technique would be better: enameling or coating with liquid acrylic. Bath enamel, like any other method, has its own advantages and disadvantages. Let's compare these methods.

The advantages of enameling include the following points:

- low cost of materials for restoration work;

- resistance of the enamel coating to a large number of chemical detergents;

- the ability to apply several layers of enamel without removing the previous layer;

- terms of work readiness are minimal.

The disadvantages of enameling the inner surface of the bath are as follows:

- restoration requires special measures to protect the respiratory tract and skin: materials for enameling work have a persistent and very pungent odor, so you will need to purchase special protective equipment for the organs of vision (industrial glasses) and breathing (respirator or gas mask);

- the enamel coating is sensitive to detergents containing oxalic acid and abrasives;

- after the restoration of the bathroom, it is necessary to use it with caution: the enamel is afraid of any, even the most insignificant, mechanical damage (a crack in the coating or a chip is formed at the site of such an impact);

- the enamel coating has a high proportion of hygroscopicity due to the porous structure of the material, so dirt is quickly absorbed into the enamel layers and is very difficult to remove from there;

- the service life of the enamel coating does not exceed a five-year period, even with all precautions and regular maintenance.

If we compare the reviews of specialists performing restoration work and consumer preferences regarding these two methods of performing restoration work and their final results, it becomes obvious that the acrylic composition is more profitable, environmentally friendly and durable.

How to prepare the surface?

Before starting the restoration of a cast iron or metal bathtub, it is imperative to make certain preparations.

- Disconnect all plumbing fixtures, but leave a drain for water. Later, it will also need to be removed, and under the drain hole of the bath, place a container for collecting acrylic material, which will drain there during the work. If the bathtub has a tiled lining, then the drain can not be dismantled, but sealed with tape, and the cut-out bottom from a polyester disposable cup can be placed on top to collect excess acrylic.

- The tiles on the wall should be protected with a wide strip of masking tape, and the floor around the bathtub should be covered with plastic or newspaper sheets.

Further actions will be the preparation of the bath surface, which must be properly cleaned with sandpaper and dried. In the event that there are chips and cracks on the surface of the bath, as well as deep scratches, the entire old enamel coating will have to be completely cleaned. To facilitate this task, it is most convenient to use a grinder or an electric drill with a wheel made of abrasive materials. As a rule, when performing such work, a large amount of fine dust is formed, therefore, cleaning the surface must be performed in a respirator and goggles.

After the surface of the bowl is cleaned, all dust and fragments of old material must be removed and the walls of the bath are washed with a damp sponge. Now the surfaces must be allowed to dry and only then treated with a solvent to remove residual grease.If for some reason it is not possible to use a solvent, it can be replaced with a thick paste made from ordinary baking soda. After processing, the soda will need to be completely washed off with hot water.

At the end of the degreasing process, all cracks and chips on the surfaces of the bathtub must be treated with automotive putty and wait until it dries completely. Automotive putty is used for the reason that its curing time is much shorter than that of other types of putty, and its adhesion to metal is quite high.

Since the restoration with liquid acrylic is carried out at a certain temperature of the surface to be treated, you will need to take hot water into the bath and wait at least 15 minutes until the walls of the font warm up. Then the water is drained, and moisture is quickly removed from the surface of the bowl using lint-free fabrics. Now you need to quickly remove the plumbing drain and the bath is ready to be coated with liquid acrylic.

How to prepare the composition?

Liquid acrylic is a two-component polymer composition consisting of a base and a hardener. It is only possible to connect the base and the hardener when the restored surface of the bath is fully prepared for the acrylic coating. It is impossible to mix the components in advance, since the resulting mixture is suitable for application in a limited period of time, which is only 45-50 minutes. At the end of this period, the polymerization process begins in the mixture, and the entire composition literally becomes thick before our eyes, its fluidity necessary to perform work is lost. After polymerization, the composition for application to the surface is unsuitable.

Mix the base and hardener that are part of the liquid acrylic, preferably with a smooth wooden stick., constantly remembering that the uniformity of the composition will largely determine the final quality of the restoration work. If the volume of the composition is large, then to speed up the process of preparing the mixture, you can use a special nozzle fixed in the chuck of an electric drill. When mixing the components of liquid acrylic with an electric drill, it is important to take into account the fact that you need to work with the tool only at low speeds, otherwise the entire composition will be sprayed around you on the walls and ceiling.

The acrylic composition must be mixed in the container in which it was placed by the manufacturer, gradually adding a hardener part by part, and only at the very end of the mixing process, add tinting paste. In the process of work, be sure to strictly follow the manufacturer's instructions indicated on the container of the material, since each mixture has its own nuances for use.

Liquid acrylic can be colored. For this, there are special tinting additives of various colors. When adding a tinting shade, it should be borne in mind that its maximum volume should not exceed 3 percent of the total volume of the acrylic mixture. If you increase the percentage towards an increase in the content of the tinting composition, this will reduce the strength of the acrylic material after the polymerization process, since the verified balance of ingredients will be disturbed and polymer bonds will not be strong enough. For liquid acrylic, only additives specially created for this purpose can be used. If you add a tinting pigment containing a solvent to the polymer composition, this will lead to the fact that you spoil all the material and it will be unsuitable for work.

Coating process

Before starting the work, the acrylic composition must withstand a certain period (usually this time is 15–20 minutes), which is indicated in the instructions for the material, and only after that the restoration can begin.The process of applying liquid acrylic to the surface of the bath consists in the fact that the prepared mixture is poured onto the walls of the bowl from top to bottom, and then the filling is leveled with a spatula, and the streaks that appear are removed. To do this, the composition is poured into a container with a small spout or into a deep volumetric glass with high walls.

Experts advise to collect a sufficient amount of material into the container for pouring acrylic. This is to cover as much surface area as possible in one pass. The fact is that excess acrylic will drain through the drain hole in the bath, and when the same section is repeated on the treated surface, volumetric smudges and sagging can form on the treated surface, which is quite difficult to level out with a spatula afterwards without damaging the resulting layer.

Initially, it is required to fill the sides of the bathtub adjacent to the wall. At the same time, the material is poured out in an even thin stream, distributing it evenly and avoiding gaps. Then the filling surface is carefully leveled using a narrow spatula with a soft rubber nozzle (using a metal spatula without a nozzle is prohibited). After that, you need to cover the outer side of the bath using the same technology. When applying a liquid acrylic mixture, it is important that it covers the old surface by about half, and that the layer of material is 3 to 5 millimeters. This completes the painting of the first circle.

Next, you need to paint the walls of the bath along their perimeter. To do this, acrylic must also be poured into the walls in a thin stream until the entire bath bowl is completely covered. At this point, the painting of the perimeter and bottom of the bowl is complete. Now you need a spatula with a rubber nozzle to even out all the beads and achieve an even distribution of acrylic over the bottom of the bowl. It is necessary to align acrylic with light tangential movements, in no case going deep into the material, as well as missing the bottom and walls of the bowl. The material evens out small irregularities during the polymerization process on its own, and all excess acrylic will flow through the drain hole into the container that you put under the bottom of the bath in advance.

Drying

After the process of applying and leveling liquid acrylic material to the walls and bottom of the bath is completed, the bulk of the work can be considered completed. Now acrylic needs time to complete the polymerization process. Usually this time is indicated on the original packaging of the material and is on average up to 3 hours. To determine the quality of work and eliminate the fluff or particles accidentally hitting the treated surface, you need to turn off the electric lighting and use a lamp with an ultraviolet spectrum of radiation: in the ultraviolet rays, all foreign objects on the acrylic material are very clearly visible. They should be carefully removed before the end of the polymerization process.

The end of the drying process in some cases takes up to 96 hours, therefore, you need to be prepared for the fact that it will be possible to use the bath for its intended purpose no earlier than this period. The polymer material dries depending on its layer thickness: the thinner the layer, the faster polymer reactions occur in it and the material hardens. During the drying process, it is recommended to close the bathroom door tightly and not open it until the material is ready for use. In such conditions, the acrylic material is better fixed on the surface of the bath, and the possibility of getting on the treated surfaces of foreign inclusions in the form of hair, wool, dust, water droplets is excluded.

The final step is to remove excess acrylic beads around the edges of the bowl - they are easily cut off with a sharp knife. Now plumbing equipment can be installed on the bath bowl, but at the same time it must be remembered that excessively tight joints are unacceptable: in those places where the acrylic material will be pinched, it is damaged.

Care

After the completion of all stages of work and the complete polymerization of the material, you become the owner of an almost new bathtub, which has a durable and smooth coating, and possibly a new color. Caring for such a font is not particularly difficult: all dirt from the surface of the bath can be easily removed with soapy water and a sponge.It should be remembered that acrylic coating is not recommended to be treated with abrasives and aggressive chemical detergents. In order for the white bathtub not to turn yellow during operation, it is not recommended to soak laundry with detergent in it for a long time, and after each use, the surface of the font must be washed with soapy water and, preferably, dried with a soft cloth.

During the operation of the restored bathtub, you should try to protect it from blows and drops into the bowl of sharp or heavy objects so that cracks, scratches and chips do not form, which will then be quite difficult to repair, and you may have to call a specialist to re-repair damaged surfaces. However, you can remove small defects in the coating yourself, and abrasive polishing will help you to do this.

To polish small imperfections in the acrylic bathtub, you will need the following materials:

- synthetic detergent;

- lemon juice or table vinegar;

- silver polish;

- fine-grained sandpaper;

- abrasive mixture for polishing;

- soft fabric, foam sponge.

The process of polishing an acrylic bathtub at home is easy to perform - just follow a certain sequence of actions.

- Before starting work, the hot tub must be thoroughly washed with a sponge with soapy water and synthetic detergents, and then rinsed with clean water. At the same time, as mentioned earlier, it is not recommended to use those detergents that contain chlorine, oxalic acid, acetone, as well as granular washing powder.

- Now you need to carefully inspect all chips and scratches and carefully grind them with fine-grained sandpaper.

- If, when examining surfaces, you see heavy dirt that could not be removed with soapy water, apply a little regular toothpaste or silver polish to them and gently treat the desired area.

- If stubborn limescale deposits appear, lemon juice or acetic acid will help you cope with the task. To do this, apply any of these products to a small piece of cloth and wipe the contaminated areas.

- Now you can apply an abrasive polish on the surface of the bathtub and gently spread it evenly over all areas using a soft cloth. In order for the polish to take hold, it is washed with a soapy solution made from a synthetic detergent.

Sometimes a small crack or chip needs to be repaired on an acrylic coating. This can be done with the same liquid acrylic that was used to restore the bath.

The technology for performing this small repair consists of several steps.

- If you need to remove a crack, first of all, you need to widen it a little with sandpaper or a knife blade so that you get a small depression.

- Now you need to degrease the surface with a detergent, which is applied to the sponge and treat the area necessary for work with it, and then rinse it with clean water.

- Next, you need to prepare an acrylic mixture by mixing the base with a hardener. You need to act according to the instructions attached to the specific material.

- Acrylic is applied to the prepared and dried area, completely filling the chip or crack groove so that the composition is flush with the main surface of the bath wall. If you apply a little more acrylic, this is not a big deal, since after the polymerization process is completed, you can sand off the excess with fine-grained sandpaper.

- After the composition has polymerized, completely hardened and dries, the surface to be restored must be polished with 1500 or 2500 grit sandpaper to smooth out all, even very small, scratches, and then polish it with an abrasive polish until it shines.

As a result of such simple actions, you can correct all the defects of the acrylic coating yourself, without resorting to the services of expensive specialists.If you handle and maintain your acrylic with care and care, your refurbished bathtub will look as good as a new product and last for years to come.

Useful Tips

We looked at the traditional way of using two-component acrylic, which is used in order to repair or restore a bathtub with your own hands. Currently, many manufacturers of polymeric materials have begun to produce compositions that do not require mixing one component with another or have other unique properties.

Let's consider the most common of these materials.

- "Plastrol". It is an acrylic material that does not have a strong chemical odor and is of the highest quality among similar polymer products. This is explained by the high concentration of active components in the composition of this material.

- "Stakril". This material consists of two components and requires mixing, but the finished product has the unique ability of a fast polymerization process, as a result of which the entire complex of work on the restoration of the bath can be completed in just 4 hours.

- Ekovanna. Liquid acrylic with high quality components, which allows you to make a durable and shiny coating on the surface of a metal or cast iron bath. If the acrylic bathtub is cracked for some reason, scratches, chips, deep cracks appear on it, they can also be repaired with this composition.

Trademarks of liquid acrylic are being improved every year.launching on the market new types of polymer compositions with modified properties. Therefore, experts recommend paying attention to such new items when choosing materials for a complex of restoration work and giving preference to brands with improved characteristics. In retail chains specializing in working with plumbing assortment, acrylic and hardener can be purchased for 1200-1800 rubles. More modified grades with improved performance may cost a little more. But in any case, these costs are incomparable with the purchase of a new bath, its delivery and installation work on installation.

During work with liquid acrylic during polymerization and in the process of pouring the material, chemicals evaporate on the surface of the bath, which do not have a very pleasant smell. Not everyone can tolerate this smell adequately. For this reason, at the time of this stage of work, people suffering from frequent headaches, allergies, bronchial asthma, as well as the elderly, small children and pets are best removed from the apartment so as not to provoke their health problems. The same circumstance is one of the reasons why it is recommended to keep the doors to the bathroom tightly closed while drying the acrylic coating.

In some cases, if the damage on the walls of the bath is deep and voluminous, which will require appropriate filling and subsequent leveling, liquid acrylic must be applied to such surfaces not in one layer, but in two layers of material. It should be remembered that the second layer of acrylic can be applied only when its first layer has completely polymerized and finally dried out. In addition, in this case, it is necessary to take into account the fact that the deadlines for the completion of work will become twice as long - it is impossible to violate or artificially accelerate the technological process of polymerization and drying using heating devices.

After finishing work on the restoration of the surfaces of the old bathtub, experts recommend not to expose the font to sharp effects of temperature changes - When filling a renewed bath, it is best to pour water warm and avoid steep boiling water.By doing so, you will save acrylic from cracking, which may appear over time due to improper use of this material. In addition, it must be remembered that any acrylic is very afraid of even small and seemingly insignificant scratches, therefore, it is best not to put metal basins, buckets, tanks and other similar objects in the bath: they can not only scratch the surface, but also leave stubborn stains on it. It is also not recommended to pour into the bath any coloring solutions, herbal decoctions, potassium manganese solution, use colored sea salt, and, if possible, avoid washing things painted with unstable aniline dyes - all this will very quickly lead to a change in the original color of the acrylic coating of the bath.

If you have planned to make major or cosmetic repairs in the bathroom, then first you need to do the whole range of necessary work and only lastly do the restoration work of the old bathroom. This is necessary in order to protect it from unforeseen damage during the repair process. The dirty and dusty stage of the main cleaning of the font surfaces can be done at any time, but the final stages with the pouring of acrylic are best done in a clean room.

Modern acrylic mixes are used not only for restoration, but also for the repair of acrylic bathtubs. If your acrylic bathtub has a crack, you do not need to wait until it gets even deeper and eventually leads to the final destruction of the structure. In addition, black mold appears in such cracks, which is almost impossible to completely remove. To prevent this from happening - do not delay this process and start repair work as early as possible.

For information on how to restore a bath with liquid acrylic, see the next video.

The comment was sent successfully.