Bolt cutters: what is it, types and application

The bolt cutter is just as necessary a tool for carrying out work in various areas of production activity, like a hammer or a shovel. Consider the varieties, classification, features of the choice and adjustment of this instrument.

What it is?

A bolt cutter, or, as it is also called, a pin cutter, is a special-purpose tool for cutting metal products and metal rods - fittings. The bolt cutter is similar in appearance to metal cutting pliers based on the concept of a double lever mechanism. There are different types of this tool:

- reinforcing pliers for metal with a mechanical hand lever;

- rebar shears using a hydraulic drive;

- end type bolt cutter, convenient for household work, for example, when cutting wire.

The range of applications for this tool ranges from home use (in a garage, in a garden area) to professional options, for example, for rescue work. Also, this tool is used in workshops for disassembling or manufacturing parts, on construction sites for working with fittings and in industrial workshops.

It should be borne in mind that the very name of the tool, which has taken root among the people, corresponds only to one of the possibilities of its use, but does not correspond to its purpose - the bolts are very rarely cut with these scissors.

Much more often, these scissors work on reinforcement, wire, steel rods. However, this name is so firmly entrenched in the bolt cutter that it is used by both ordinary people and professionals.

Specifications and classification

The bolt cutter, as the most versatile tool, does not have a number of technical modifications, since the principle of operation for all types is practically the same. So, the end type will correspond to ordinary wire cutters; The pneumatic bolt cutter differs from the hydraulic only in that it uses air pressure instead of oil. In this case, the hydraulic bolt cutter will work on the principle of oil pressure on the piston, using an installed (or stationary) pumping station, and the pneumatic bolt cutter will use the compressor.

It is customary to distinguish several classifications of this tool, depending on the field of application:

- manual (mechanized);

- professional (large);

- reinforced (equipped with hydraulics or long handles);

- rechargeable;

- end;

- pneumatic;

- dielectric.

The principle of operation is the same regardless of the classification, however, each tool has a different power density and transmission method. For example, there are manual bolt cutters with a double wishbone or hydraulic drive, where the cylinder rod is connected to the moving part of the cutter head.

The types of bolt cutters that are specialized in a particular field of application are classified as professional. So, for example, the bolt cutter for rescue operations will be equipped with a battery electric motor and hydraulic drive to speed up rescue operations. It will also have a small weight and dimensions, taking into account the specifics of the field of application, but it will not lose strength in this case.Another example is the dielectric bolt cutter, which, in addition to the standard overlays on the handles, will completely isolate the voltage in the cut steel wire, having special protection, which also takes into account the specifics of the application.

Views

The following modifications of bolt cutters are most commonly used.

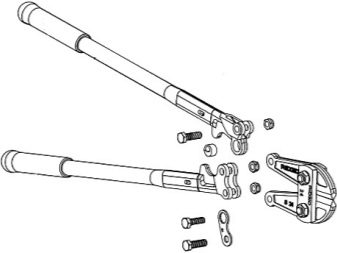

Manual (mechanized) bolt cutter, which is a scissors with a lever drive. The device allows you to combine two lever mechanisms in the design (Fig. 1, 2): the head of the pliers with cutting edges pivotally connected to the crossbar, and long handles-shoulders connected by the ends.

The handles of such a bolt cutter are connected on the side of the articulated connection with the head of the jaws, which forms a double lever mechanism.

Due to the shoulder difference, a good gear ratio is created. With this arrangement of the mechanism, the force is transmitted from the handles to the cutting head-nippers, which determines a small stroke, but gives a significant transmission moment to the object being cut.

The handles of this tool are made of steel and are usually protected by rubber pads. Nippers are made of steel, hardened by high frequency currents. The edge of the cutting jaws is symmetrically sharpened at an acute angle, so it would be more correct to call this tool nippers rather than rebar scissors.

The cutting edge (jaws) can be of two types:

- angular, in which the axis of the head is distributed at a relative angle from the axis of the handles;

- straight lines in which the axis of the head coincides with the axis of the handles.

The characteristics of manual bolt cutters are determined by two indicators:

- long handles;

- the maximum allowable cross-section of the rod, which "takes" this tool.

The length of the handles of the hand bolt cutter can be from 200 to 1115 mm. If the length of the handles is up to 200 mm, this tool is classified as a pocket tool. Bolt cutters longer than 350 mm are classified as large and are divided according to the scale of inches. So, such a tool can have a length of 14/18/24/30/36/42 inches.

At the same time, the type of bolt cutter with a total length of 18 to 30 inches (600 mm, 750 mm, 900 mm), which has an alloy steel cutter head and a special protective coating for working with purebred types of steel, is called reinforced.

Hydraulically Operated Manual Bolt Cutter (Fig. 3) is based on the action of the same lever principle as the mechanical one, however, the main effort when working with it is aimed at pumping the hydraulic cylinder with which this tool is equipped. After the piston of the cylinder is set in motion, pressure is created inside it, which drives the piston of the cutter. The gear ratio, in contrast to a conventional manual bolt cutter with a two-lever mechanism, is much higher in this case, and therefore this type of bolt cutter does not need long shoulder handles.

The sharpening of the lower part of the head of the pliers is made according to the same principle as on scissors, that is, the movable part of the head is sharpened on one side, and the fixed part is made in the form of a sharp-edged plate. The location of the jaws of the pliers lies in different projection planes, which is why the hydraulic bolt cutter works like a scissors, cutting the rod.

Based on these features, it becomes clear that the bolt cutter with a hydraulic drive can deservedly be called a hydraulic shears (Fig. 4).

Hydraulic shears with manual pressure applied to the cylinder piston can rightfully be called reinforced, since the applied forces are reduced to a minimum due to hydraulics. An additional advantage of the design is its relatively low weight. The force is transmitted by means of the tool handle, to which is attached a piston outlet located inside the cylinder. A manual hydraulic bolt cutter has a noticeable superiority over a conventional double-lever bolt, but loses in performance to a tool equipped with an oil pump.

For the hydraulic bolt cutter to work with the pumping station, an additional oil supply from the pump is required. This type of scissors is connected to the pumping station using a high pressure hose. A feature of the complete set of the hydraulic bolt cutter includes replaceable heads of different types of nippers, which makes this tool universal. The principle of operation is the same as the operation of a manual hydraulic bolt cutter, however, the main effort on the material being cut is created by the pressure that arises when pumping the cylinder with the supply of oil from an oil pump or pumping station.

Electro-hydraulic bolt cutter - the most advanced version of scissors for cutting metal reinforcement. An electric oil pump is built into this type of bolt cutter, which supplies oil to the cylinder through a high pressure hose. To work with this type of bolt cutter, an electrical network is required, although there is a modification for working in places that are not equipped with electrical wiring, which is equipped with a battery. The electro-hydraulic bolt cutter, like its more modest brother, is equipped with replaceable attachments for working in various conditions.

How to choose?

You shouldn't skimp on the cheapest kind of bolt cutter. This can lead to injury and annoying damage to the instrument. The bolt cutter should be chosen after knowingly studying the upcoming front of work with it. For work on a farmstead, ordinary, end, pocket models of bolt cutters with handles up to 30 cm long are suitable. For work in a workshop, it is best to purchase a mechanical type hydraulic shears.

It should be borne in mind that the tool must be used correctly, that is, when buying, it is important to correctly assess the range of capabilities of a particular device.

The defining points when choosing a bolt cutter are:

- scope of application;

- maximum cross-section of the metal to be cut;

- price.

In the store, before purchasing a bolt cutter, you should pay attention to several nuances:

- when the handles are closed, there should be no gap between the nippers;

- you should not buy a bolt cutter with hollow tubular handles - such a tool will not last you long;

- a tool with tool steel handles, as well as a hinge mechanism, will perform best.

Rating and modifications

There are a large number of domestic and foreign manufacturers of this type of instrument.

- The most popular are manual bolt cutters of the brand Matrix (China) with a price from 600 to 1500 rubles, depending on the length of the supporting handles.

- The tool of domestic production of the brand is no less popular. "Techmash", the price threshold of which is slightly higher than the Chinese manufacturer. However, there is no need to focus on the attractive cost of the Chinese product, since it is inferior to the domestic brand in quality.

- Another no less popular manufacturer of bolt cutters on the market is the domestic brand "Zubr"... At a not very high price, this company offers for domestic use a bolt cutter made of a special alloy of steel with forged connectors with dielectric handles.

- Reinforced bolt cutter German brand StailerMaster can please with the quality of the connector and nippers, also made of a special alloy. The prices of this manufacturer are quite reasonable considering the requirements of the European market.

- The brands Fit, Knipex, Kraftool you can also find models of bolt cutters for both individual and industrial work.

Application

Before you start working with the bolt cutter, you need to carefully prepare it: you should check the integrity of the mechanical components, the power steering cylinder, the high pressure hose, as well as the battery terminals.

When working with any type of bolt cutter, it is necessary to follow a number of specific rules that allow you to effectively use the tool and reduce the level of injury when working with it:

- when cutting metal or a rod (including the bows of the locks), it is necessary to stabilize its original position as much as possible and prevent the tool from moving from the desired mark;

- if you use a bolt cutter to dismantle a hinged structure, it is necessary to take into account the possibility of falling parts of the structure and pre-fix them additionally;

- the most productive work result can be achieved by having an additional tool at hand for ancillary work.

If necessary, the bolt cutter can be adjusted to adjust the plane of the cutters using the hinge mechanism.

To do this, the handles of the tool are bred and the gap formed in the process of work is eliminated using a hinge mechanism and a crossbar.

Operating rules

It is required to carry out work in special clothing, always in gloves and glasses, since there is a possibility of scattering of the elements of the cut reinforcement. Shoes should be tight and provide good protection for your feet. If work with the bolt cutter is carried out at a height, it is necessary to fasten the safety cable to a strong metal element that is not involved in work or dismantling. The handles of the tool must be dry.

Do not leave the tool outdoors after work. It is best to store the bolt cutter in a dry, enclosed area. Do not overload the bolt cutter - you should initially study the maximum allowable power set for each modification. You should not use this tool in those types of work for which it is not intended. After finishing work, the bolt cutter must be cleaned of dirt and small debris must be prevented from entering the mechanism. The hydraulic models of bolt cutters are especially "capricious" in this regard. Scratches on the piston mirror, for example, will quickly damage the hydraulics.

The recommendations given in this article will help you choose the right tool, such as a bolt cutter, that is necessary in many types of work, and also work with it correctly.

Then watch the video review of the Zubr bolt cutter.

The comment was sent successfully.