All about wire rods 8 mm

Rolled wire is a ready-made raw material for the production of galvanized steel wire rod, fittings, ropes, wires and cables. Without it, the production of electrical and radio engineering, special vehicles, the construction of frame houses and a number of other types and varieties of human activity would have stopped.

Features and requirements

Steel wire rod has increased strength and hardness, which makes it a suitable base for the production of smooth round and oval cross-sections, ropes, hangers for copper and optical cables, nails, welding electrodes and welded wires, staples with a round cut. A common cross-section of rolled wire is perfectly round, less often oval.

The diameter of rolled wire is from fractions of a millimeter to 1 cm. The most popular is the section of rolled steel wire of 5–8 mm.

Copper wire is often 0.05–2 mm thick, as evidenced by the winding of motors, wires and central conductors of coaxial cables, multicore cables. Aluminum is mainly used as wires and cables for power lines - the cross-section of one rod reaches a centimeter. In the latter case, an aluminum cable is used suspended on ceramic insulators of the posts. Insulated and sheathed cables have a cross-section sufficient to withstand hundreds and thousands of kilowatts taken by the consumer from the transformer substation.

Wire rod, like other rolled ferrous metal profiles, is suitable for lightning rods that provide lightning protection.

In the production of wire rod, they adhere to GOST 380-94. The manufacture of wire rod according to TU for fittings and wires is not allowed. Broken wire rod can cause a high-rise building to collapse (steel reinforcement will break, the reinforced concrete frame will crack, shift, and the building will become emergency) or cause a fire (aluminum wires and cables under significant stress). Exceeding the permissible amount of impurities, such as sulfur, will make the steel unnecessarily brittle. Low carbon steel will not acquire the hardness and strength sufficient to, for example, hammer nails into wood.

These and many other features are monitored by specialists, checking in accordance with GOST. Wire rod weight and diameter are regulated by GOST 2590-88. Steel wire is produced with ordinary (C) and high (B) accuracy in terms of diameter and weight. The rolled oval should not be more than half the sum of the maximum difference in diameter.

The curvature of the wire does not exceed 0.2% of its length. This indicator is determined on a segment of at least 1 m, located at a distance of more than 1.5 m from the edge.

The weight of 1 meter of 8-mm steel wire rod according to GOST is 395 g. For 9 mm - 499, for 10 mm specific weight of a running meter - 617 g. Wire rod should not break at 180 ° bend (turn of the rod in the opposite direction). With a single bend, microcracks should not form. The diameter of the power pin, by which the wire rod is checked for bending, is equal to the diameter of its section.

How do

Wire rod production is one of the simplest metal rolling methods. Simply put, rolled wire - a round profile whose diameter, unlike a pipe, is less than 1 cm. It makes no sense to produce a wire of a larger cross-section (with the exception of reinforcement up to several cm in diameter): the costs of metals and their alloys would be very high.

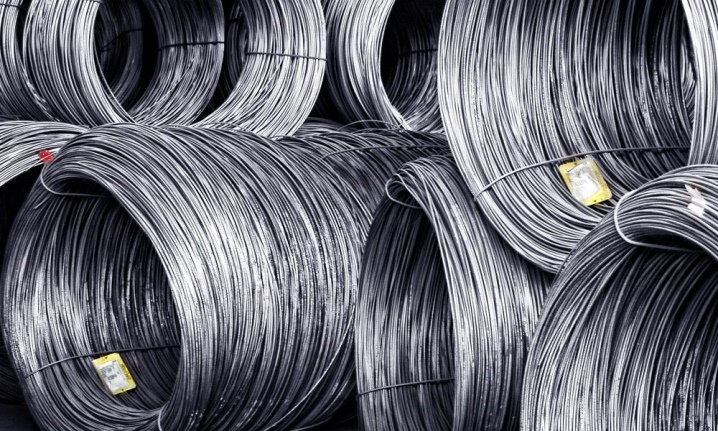

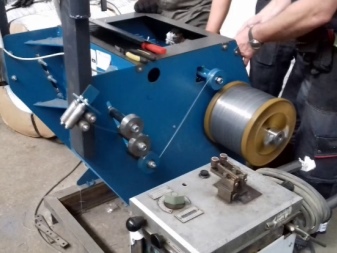

The billet in the form of a long, multi-meter bar is rolled out on a rolling machine-conveyor. The metal or alloy is heated and stretched, passing through the guide shafts that define the section and diameter. The red-hot wire rod is wound on the reel of the winding machine, which forms a ring-coil.

Free cooling can soften the material from which the wire rod has just been drawn. Accelerated - blown or immersed in water - will give the metal or alloy additional hardness.

Free-cooled wire rod is not tested for scale mass content. With accelerated cooling, according to GOST, its share should not exceed 18 kg per ton of finished product. The scale is chipped either mechanically (using steel brushes, scale breaker) or chemically (passing the wire through dilute sulfuric acid). The use of concentrated sulfuric acid quickly and easily reduces the scale, but also thinns the useful section of the wire rod.

To eliminate the effect of saturation of the metal with hydrogen and to prevent the appearance of brittleness during etching, sodium orthophosphate, table salt and other salts are used, which slow down the excessive corrosion of rolled wire during its processing.

Views

The coating applied to the wire rod is either hot sprayed or anodized. In the first case, hot zinc powder is applied to steel wire, from which the scale (iron peroxide) has been previously removed.

This is how galvanized wire is obtained. The process requires a temperature of 290–900 ° C, it is called diffuse.

Zinc is also applied by anodizing, dissolving a zinc-containing salt, for example, zinc chloride, in an electrolyte. A constant current is passed through the train. A layer of metallic zinc is released on the cathode, and on the anode - in this case, chlorine, which is determined by smell in laboratory conditions. Copper plating of aluminum (to save copper) is also performed by anodizing. The scope of application of copper-bonded aluminum conductors is signal cables for low-current systems, for example, networks of security and fire alarm systems and video surveillance.

The cold method involves applying a protective coating to the wire rod that has just been descaled. The polymer (organic) composition acts as a basis, but such a wire is afraid of overheating above several tens of degrees above zero.

The gas-dynamic method allows galvanizing a product made of steel of any shape. Its principle of operation is based on a hypersonic flow of a spray-applied gas.

Hot dip galvanizing is the best method. Hot-dip galvanized bar will last much longer than exactly the same product processed by other methods. For this, wire rod or other product is placed in a bath in which zinc is melted. After extraction, zinc is oxidized, then carbon dioxide is added, and zinc oxide is converted into zinc carbonate.

At the end of the production process, the finished wire rod is delivered to retail outlets, wholesale buyers (for example, construction companies) or sent to other factories that produce nails and rebar. For individuals, rolled wire is sold in diameter less than 8 mm and in much smaller quantities than wholesalers.

Steel wire rod, according to GOST 30136-95, is produced as measured, unmeasured and several times higher than the measured value.

The length of the rod is determined by the composition of the steel.

For low-carbon steels, the rolled bar has a length of 2–12 m: the less carbon in steel, the more ductile it is. Steel with a high coal content is produced in the form of rods of 2–6 m. High-carbon steel, which is of high quality, allows the production of rods of 1–6 m.

The comment was sent successfully.