What is the difference between C20 and C8 corrugated board?

All owners of private houses and public buildings need to understand what is the difference between corrugated board C20 and C8, how the wave height of these materials differs. They have other differences that are also worth highlighting. Having dealt with this topic, you can clearly understand what is better to choose for the fence.

Differences in the profile section

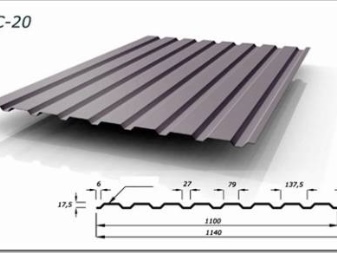

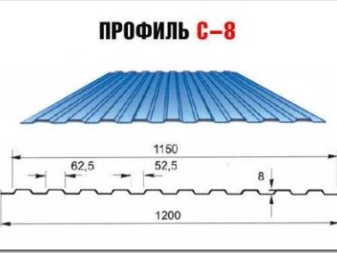

It is this parameter that should be given special attention. More precisely, not one parameter, but three characteristics of the profile sections of the material at once. Leaf C8, which is clearly visible at the first glance, is symmetrical. The wavy sections located above and below have the same size - 5.25 cm. If you look at C20, you will immediately find a pronounced lack of symmetry.

The wave from above is only 3.5 cm wide. At the same time, the width of the lower wave is increased to 6.75 cm. The reason for this discrepancy is purely technical considerations.

From the aesthetic point of view, it is difficult to find special differences. The so-called profiling step is also important.

The C20 has much more separation distances. They are 13.75 cm. But the professional sheet of category C8 is divided by waves with a break of 11.5 cm. In the "eight" it is still difficult to find differences between the sides of the surface. The whole difference is determined only along the perimeter of the sheet, but it is. But for C20, the characteristics directly depend on the choice of the facade plane; if such a sheet is placed in a wave upward, the dispersion of the load will improve; with the opposite method of laying, water is more efficiently removed.

But there are some other differences between these profiles. C20 profiled sheet can be equipped with a capillary groove. Products of the 8th category do not have such a side groove. When the structure is installed with an overlap on the roof, it is hidden from the outside by the material - and still effectively removes water. The capillary channel reduces the risk of roof leaks, even if minor damage to the integrity of the coating appears; its presence is usually denoted by the symbol R in the marking (according to the first letter of the English word "roof").

How do the heights of the waves differ?

Decking C8, as you might guess, is made with waves 0.8 cm high. This is the minimum value for a commercially available profile in general. It is impossible to buy a product with a smaller wavy part either in our country or abroad - there is simply no point in such products. C20 profiled sheet comes with a trapezoid with a height of not 2, but only 1.8 cm (the figure in the marking is obtained by rounding for greater persuasiveness and attractiveness). For your information: there is also an MP20 profile; his waves are also 1.8 cm high, only the purpose is different.

The difference of 1 centimeter only seems to be a minor nuance. If we compare the waves in proportion, the difference reaches 2.25 times. Engineers have long found out that the bearing characteristics of profiled metal depend precisely on this indicator. Obviously, because the C20 profiled sheet has a much higher permissible load.

Increasing depth also means better drainage of fluids from inclined surfaces.

Comparison of other characteristics

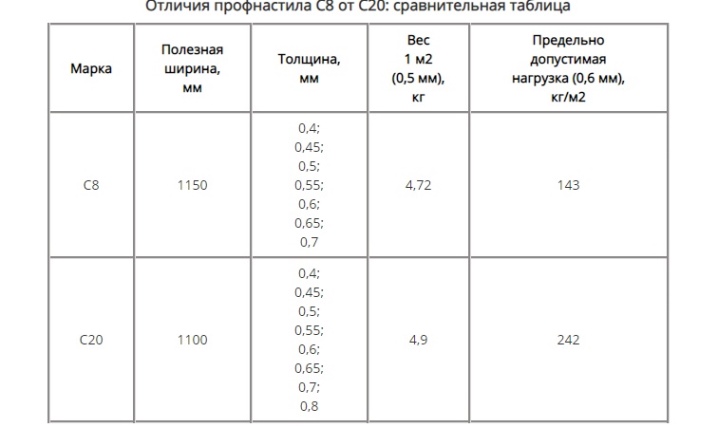

But the difference in wave height between C20 and C8 corrugated board affects other important parameters. Their smallest thickness is identical - 0.04 cm. However, the largest metal layer is different, and in the "20th" it reaches 0.08 cm (in his "rival" - only 0.07 cm). Of course, increasing the thickness allows for greater mechanical strength.But this does not mean that thicker material definitely wins in every possible case.

Intermediate thickness values are as follows:

-

0,045;

-

0,05;

-

0,055;

-

0,06;

-

0.065 cm.

Differences in professional sheets are also associated with the severity of a particular material. Most often, in the descriptions of manufacturers, it is indicated for an average thickness of a product - 0.05 cm.It is 4 kg 720 g and 4 kg 900 g, respectively. Of course, there are differences in the maximum permissible load - indicated per sheet 0.6 mm; it is equal to 143 kg for the G8 and 242 kg for the G20.

More specific information can be found in the specific product data sheet.

Other important points:

-

both types of sheets are produced by cold rolling;

-

they are resistant to corrosion;

-

С8 and С20 perfectly withstand climatic influences;

-

the length varies from 50 to 1200 cm (with a standard step of 50 cm).

C20 professional sheet is a little heavier. However, you will hardly be able to feel a special difference. The overall dimensions are 115 cm, the useful width is 110 cm. For the C8, these figures are 120 and 115 cm, respectively.

Both sheet options can be coated with a polymer layer, which increases the cost of the product, but increases their service life.

What is the best choice?

It may seem that for the fence it is worth choosing an unambiguously stronger and more stable material. It is sometimes believed that this will allow you to better protect yourself from bullies and other intruders. There is also an opposite opinion: it seems that the barrier can be built from any sheet, and even choose the lightest type of it correctly in order to reduce the load. But both of these theses are only partially correct and do not allow making a clear choice between C8 and C20. Profile sheet C20 is designed for increased static and dynamic loads.

Therefore, it is appropriate for areas where strong wind loads are likely. In Russia, these are:

-

St. Petersburg and the Leningrad region;

-

Chukotka Peninsula;

-

Novorossiysk;

-

the shores of Lake Baikal;

-

north of the Arkhangelsk region;

-

Stavropol;

-

Vorkuta;

-

Primorsky Krai;

-

Sakhalin;

-

Kalmykia.

But it is not too important to take into account snow loads - if we are talking about a fence, and not about a roof, of course.

But still, snow can press on fences - therefore, in the most snowy areas, you should also prefer a stronger material. C8 is well replaced by C20 sheets, but the opposite replacement is categorically undesirable. This can lead to the destruction of the main structures. And in terms of security from outside intrusions, the strength of the fence is quite relevant, therefore, it is also necessary to take into account the activity of crime.

C8 is characterized as an exclusively finishing material. It can be applied:

-

for interior and exterior wall cladding;

-

for the production of prefabricated panels;

-

when filing eaves;

-

when constructing a utility block, a shed in places with a minimum wind intensity.

C20 is more correct to use:

-

on the roof (on a solid crate with a significant slope);

-

in pre-fabricated structures - warehouses, pavilions, hangars;

-

for awnings and canopies;

-

when arranging the roofs of a gazebo, veranda;

-

for framing the balcony.

The comment was sent successfully.