Everything you need to know about printer toner

Laser printers today are used not only in office premises, but also at home. Their advantages are maintenance benefits and multiple refills of cartridges. Let's consider what a toner is, what it is, what advantages and disadvantages it has. In addition, we will tell you what problems you may encounter when using it and help you solve them.

What it is?

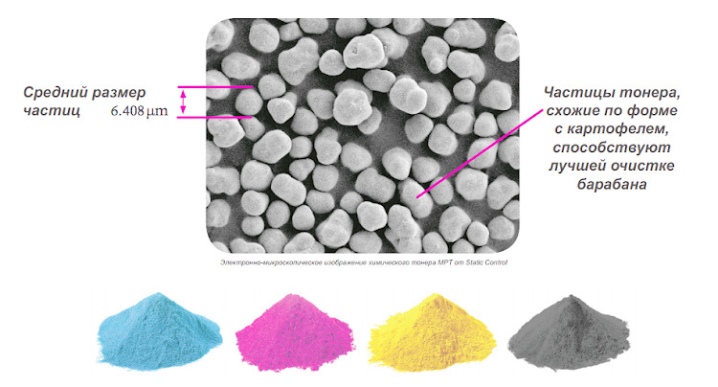

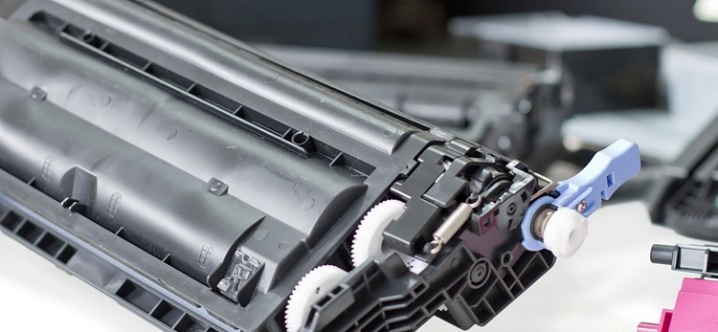

Toner is a special powder paint for a printer. The ink powder can be colored or black depending on the variety. It is a light-alloy finely dispersed substance that is used to fill cartridges and copiers of laser printers. Its particle size ranges from 5-30 microns. Ink powder is produced in 4 colors: black, red, blue and yellow. During printing, colored inks are mixed with each other. This allows you to achieve different shades on the printed paper.

Toner is produced on special equipment using polymers and dyes. The use of toner produces images with pleasing texture and depth. The first toner particles had a faceted shape. Today they are distinguished by their rounded shape, which achieves high definition of the image, gradation and smoothness of tones.

In addition, it prevents rapid wear of the printing mechanism.

Advantages and disadvantages

Refillable consumables have many positive qualities:

- variability of composition and type of manufacture;

- availability for a wide range of buyers;

- high productivity without loss of print quality;

- the ability to continuously print a large volume of documents;

- long trouble-free operation at every refueling;

- low cost of printing files and images;

- resistance to the environment and moisture.

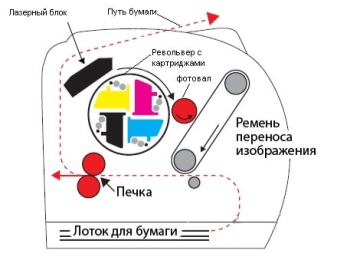

The microscopic particles of the toner powder are highly electrified. Due to this, they reliably adhere to the charged areas on the surface of the imaging drum of the printing device. Toner is susceptible to temperature changes.

Monochrome printers use only black powder, color printers use all 4 colors. The advantage of powder paints over flood or UV inks is the ease of refilling. They do not need hose systems and the dyes do not dry out. There is no need to clean and rinse the hoses when the equipment has been idle for more than two weeks. In this case, heating to the desired temperature occurs very quickly.

Along with its advantages, laser toner also has disadvantages.

Although inkjet ink is afraid of water, it produces better image quality. This is especially noticeable when printing photographs on photographic paper.

Toner is inferior to conventional liquid ink when you need to print something, for example, on coated cardboard or letters. Typically, toner will peel off over time. If desired, you can easily scratch it off with your fingernail. When printing with ink, the image cannot be erased.

Toner is not at all environmentally friendly. When inhaled, particles are deposited on the lungs. Sometimes, when refueling, symptoms of asthma, cough and allergies can occur. It becomes safe only when it is heated to a certain temperature. It melts at a temperature of 200 degrees. Do not allow it to enter the respiratory tract. You need to fill the powder very carefully, using a protective mask and gloves.

As for the economy, then color powder for color printers is considered less economical. The black dye usually lasts for a long time. Often, the counter is already working, and there is still a lot of powder inside.

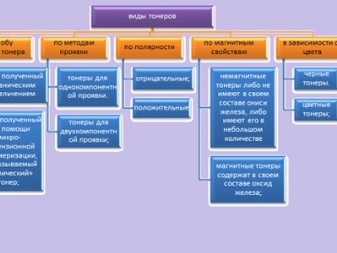

Species overview

There are various criteria for classifying printer toner. For example, according to the type of charge, it can be positively or negatively charged. In the assortment of manufacturers, you can find consumables for different models of printing devices.

By type of manufacture

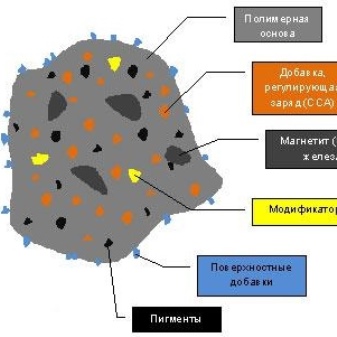

Based on the manufacturing technology, toner can be mechanical or chemical. Variants of the first group are distinguished by the sharp edges of the particles. They are made from a polymer base, SSA additives that regulate the charge, as well as surface additives, modifiers, pigments and magnetite. This method of obtaining today is losing its relevance.

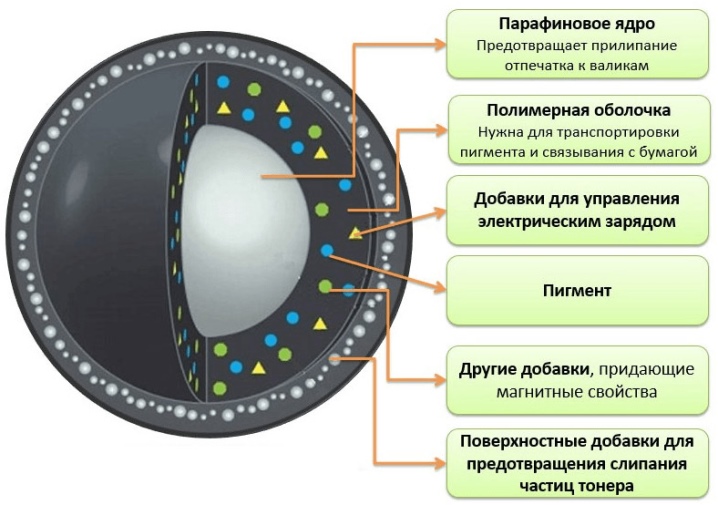

Chemically produced toner is produced by emulsion aggregation. This manufacturing method is not so harmful to the environment, which is why it is used more often. The basis of the granules is a paraffin core, which prevents the print from sticking to the rollers. In addition, it is composed of a polymer shell, additives to control electrical charge, pigment, surface additives to prevent toner particles from sticking together.

In addition, today they release and biotoner... Reed, soybeans, corn are used in its production. Usually the percentage of natural ingredients does not exceed 1/3 of the total weight of the powder.

In the future, manufacturers plan to reduce the volume of chemical components to 1/2, replacing them with natural ones.

By composition

The composition of the toner varies depending on the type of toner. It usually consists of a binder, paint, baking powder and a charge carrier. Variants of the chemical type, consisting of a paraffin core, a polymer shell, may differ in additives that determine the properties of the coloring powder. Each component of the composition has its own meaning. For example, a polymer base is needed to hold smaller particles near the core. Magnetite is required to improve paper transfer of toner and reduce dustiness.

As for the type of polymer, depending on the type, it is polyester or styrene-acrylic. Polyester printers are excellent at printing files at an optimally low temperature. They save energy and deliver fast print speeds.

All types of toners for laser printers are divided into 2 types: magnetic and non-magnetic. Iron oxide is included in the magnetic modifications. They are distinguished by direct interaction with the magnetic roller located in the printer. This form of ink does not need intermediary mechanisms for transferring to the drum. The magnetic particles are enclosed within the polymer shells.

The non-magnetic type of toner differs in that it is transferred to the drum unit using a developer (media). In this case, monochrome (black) powders are usually magnetic, and colored ones are non-magnetic. Polymers have no color.

Compatibility

In terms of toner compatibility, toner is genuine, compatible and counterfeit. Original is the toner that is made by the company that manufactures the printers themselves. Usually, such powder ink is sold together with a cartridge for a specific device. The key disadvantage of this toner is its high cost, so it is not bought so often. Compatible type powder is in high demand. It is produced by various brands, observing the requirements of manufacturers of printing equipment in terms of properties and characteristics.

Such a product is sold in plastic jars, has a reasonable price and is considered a universal printing consumable. In addition to original and compatible toner, there are also counterfeit products on the market. Its price is much lower, but it is not suitable for high-quality printouts. It can cause serious damage to the printing device.It is made from low-quality raw materials without observing production technology.

Selection Tips

The ideal toner is the original ink in the cartridge. The powder filled in production conditions gives a clear print without defects. Such a consumable does not leave spots and streaks on the pages, it does not damage the laser printer. However, if it is not possible to often purchase original paint, you have to limit yourself to its analogue.

In this case, several purchase criteria must be considered.

- You need to purchase a consumable only from a trusted seller in a store with a good reputation. Before buying, you can flip through reviews about the store by visiting a couple of thematic forums.

- To make sure of compatibility, you need to carefully study the characteristics on the packaging, selecting them for a specific model of the printing device.

- The label should contain information about the brand of the printer, manufacturer, composition, storage recommendations.

Conditional versatility does not mean that toner is suitable for absolutely all types of printing devices. This generally means that it is suitable for printers recommended by the manufacturer that produces them. For example, Hi-black toner is compatible with virtually any HP cartridge. The exception is the HP-436 printer.

When buying powder paint, you need to pay attention to the price of pigment or black powder. Toner is not suspiciously cheap; low price speaks of counterfeit products. In addition, it is worth taking a closer look at the labeling: for counterfeit products, it does not coincide with the original.

As for the amount of toner, it all depends on the needs. For a home printer, it is enough to buy a powder of 100 g. Large network printer companies purchase large volumes of toner. The maximum can be 10 kg.

As far as practicality and benefits are concerned, it is best to buy toner from cans. Depending on the volume, it can be poured into the cartridge several times. Powder-filled cartridges are uneconomical and are generally rated for fewer print units than advertised. In addition, their price in most cases is more than half the cost of a new printer. At the same time, the buyer pays half of the price for the promoted brand.

Compatible inks cost half the price of original. It is a great choice for printing text files and PDF documents.

Features of use

When buying toner, you need to consider its performance. Ordinary black powder lasts for a long time if there is no chip in the device that stops printing after the counter is triggered. If this is a new printer with an original demo cartridge, there will be enough toner for 50 color (35-40 in real life) and 500 monochrome pages (about 350). All subsequent cartridges have a high yield. Their capacity can reach 2000-3000 A4 pages according to the manufacturer's declared characteristics. In fact, this number is less by about 200 pages.

However, the capacity depends on the percentage of the paper filled. For example, if the toner consumption is 16%, there is enough powder for less than 800-900 pages. The cartridge yield depends on the print settings, the state of technology and the quality of the paper used. The denser the drawing, the more paint goes to it. Printing text is considered more economical.

The original toner cartridge is inserted into a special compartment until it clicks. After that, the device is connected to the mains. When the chip is triggered, the printer is ready for use. The countdown of pages begins, the resource for a particular model may differ.

If you need to pour powder into the cartridge, you must follow the manufacturer's instructions attached to the specific model of the printing device. During refueling, you need to clean the sump and pour the toner into a special compartment. After that, the print counter is reset and the cartridge is inserted into place.

You need to work with gloves - the toner is volatile and can settle on objects in the room. When refueling, you need to open the window. As for the capacity control, it will not be possible to check the level of the consumable until the notification. When it ends, a warning window opens on the monitor screen.

You can also tell when a toner is near the end of its life when the orange light on the printer panel starts blinking.

Possible problems

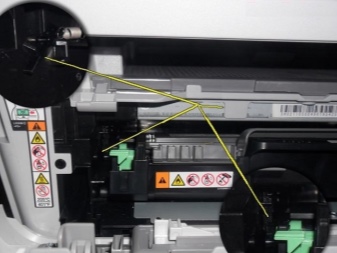

If a laser printer does not print well, this may indicate various reasons. For example, this happens when the drum unit is worn out. In this case, the only solution to the problem is to replace it. In addition to the wear of the photo roll in the cartridge, the reason may be the dusting of the laser in the device.

It happens that the printer does not see the powder container after refilling. In this case, it is necessary to reset the counter, restart the computer and the printing device itself. The reboot scheme for the printer is included in the package and may vary from manufacturer to manufacturer.

As for other problems, then you need to act depending on the specific reason.

- If black vertical stripes appear at the edges of the sheet in a monochrome printer, you need to change the drum unit, and often the squeegee (cleaning blade).

- If stripes remain after refueling, you need to pull out of the printer and disassemble the cartridge. And then clean the waste toner box.

- If horizontal stripes appear on the page during printing, repeating at regular intervals, you should check the printer for problems with the magnetic roller. In addition, this problem indicates the need to clean the contacts of the magnetic roller and the side cover of the cartridge.

- If the laser printer does not print well after refilling, this may indicate clogged filters.

- When the printer is too dim, you need to check the print settings. Economy mode is probably selected.

- If a red light is on, it may indicate a paper jam in the product. You need to open the lid and carefully pull it out with a single sheet.

- If there is ink, but the printer does not print, and the computer does not see the printer, you need to check if the contacts are loose.

- A light print tone indicates poor toner quality. The problem is solved by purchasing high-quality consumables.

- Dull and faint print may be due to toner adhering to the oven of the device, which bakes the powder paint. It happens that toner sticks to the upper roller of the fuser.

When printing out not white, but black sheets, the layman often does not know what to do. However, it is not difficult to solve the problem: this happens when the cartridge contacts are not tight, the drum is lit, and the cartridge is not assembled correctly (the charge roller was not inserted into it).

When buying self-refilling toner, keep in mind the constant cleaning of the waste bin. If it is overfilled, the powder will start to spill directly onto the paper, so dots and spots will appear on it.

In the next video you will find a comparison of toners Patron HP universal # 1 and SCC AX \ HP1100 MicroGraphics.

The comment was sent successfully.