What are dot matrix printers and how do they work?

Dot matrix printer is one of the oldest types of office equipment, printing in them is done thanks to a special head with a set of needles. Today dot matrix printers are almost universally superseded by more modern models, however, in some areas they are still widely used today.

In our review, we will look at the features of the operation of this device.

What it is?

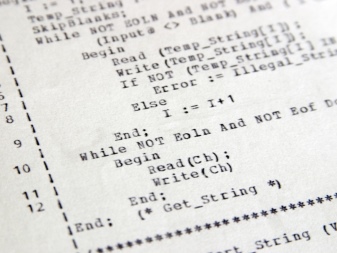

The operation of a dot matrix printer is based on the decision to type text data not from the already prepared symbols of the printing device, but by connecting separate dots. The basic difference between matrix-type models from the laser ones that appeared a little later, as well as inkjet models, is in the technique of applying dots on sheets... Matrix devices seem to knock out the text with the blows of thin needles through the ink ribbon. At the moment of impact, the needle firmly presses a small piece of toner against the paper and makes an impression filled with ink.

Inkjet printers form a picture from small droplets of ink, and laser printers from electrically charged dye particles. The simplicity of the technology made the dot matrix printer the most durable and at the same time the cheapest.

History

The first surge in demand for dot matrix printers came in the 70s of the last century. During that period, DEC devices were widely distributed. They allowed typing at a speed of up to 30 characters / s, while being characterized by a small line size - depending on the design features, it varied from 90 to 132 characters / s... The ink ribbon was pulled by means of a ratchet mechanism that worked quite sonorously. With the development of the industry, higher-quality models appeared on the market, which are widely used not only in production, but also in everyday life. The most popular was the Epson MX-80 printer.

By the early 90s, inkjet printers were launched on the market, which were characterized by increased print quality and at the same time worked almost silently. This led to a significant reduction in the demand for matrix models and a narrowing of the scope of their use. However, due to the low price and ease of operation, the matrix technology remained indispensable for a long time.

Device and principle of operation

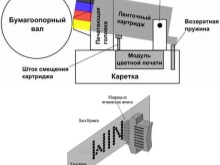

It is not at all difficult to describe the mechanism of action of a dot matrix printer. The most complex and expensive working element in the device is the head located on the carriage, while the functional parameters of the mechanism directly depend on the design features of the carriage.... There are electromagnets in the printer body, they pull in or push out the core, in which the needles are located. This part can only print one line per pass. The ribbon cartridge looks like a plastic box with ink ribbon inside.

The printer is equipped with a paper feed drum to feed sheets of paper and hold them during printing. To ensure maximum adhesion to paper, the drum is additionally covered with plastic or rubber.

In addition, rollers are built into it, which are responsible for clamping the sheets in the drum and supporting them during the printing phase. The movement of the drum is carried out by means of a stepping motor.

In the additional case, there is a special device responsible for feeding the sheet and maintaining it until it is tightened. Another function of this structural element is the correct positioning of the text. When printing on roll paper, this device is additionally equipped with a holder.

One of the most important elements of every dot matrix printer is the control board. It contains the control module, internal memory, as well as the interface circuits necessary to ensure stable communication with the PC. Thus, its main purpose is to help the device perform all its basic functions. The controller board is a small microprocessor - it is he who decrypts all commands coming from the computer.

Typing with a matrix device is carried out at the expense of the head. This element includes a set of needles, the movement of which is carried out by electromagnets. The head moves along the built-in guides along the sheet of paper, during the printing process the needles hit the sheet in a certain program, but first they pierce the toning tape.

In order to obtain a particular font, simultaneous strokes of several needle combinations are used. As a result, the printer is capable of printing almost any font.

Most modern matrix devices have the option of controlling the needles from a PC.

Advantages and disadvantages

Matrix technology is outdated these days, however, these printers have many advantages.

- The main advantage of dot matrix printers is their affordable price... The cost of such equipment is ten times lower than the price of laser and inkjet devices.

- The period of operation of such a printer is much longerthan the time of using other types of devices. The ink ribbon never dries up suddenly, this can always be noticed in advance, since in this case the print contrast gradually decreases, the text becomes fainter. All other types of printers can complete their work at the most inopportune moment, when the user simply does not have the opportunity to charge the cartridge on time.

- You can print files on a dot matrix printer on any type of paper, and not only on a special one, as is the case when using inkjet and laser products. The printed text is highly resistant to water and dirt.

- Printing mechanism allows you to reproduce a document of the same type.

Despite such weighty advantages, this technique also has its drawbacks, which make the matrix technique absolutely unsuitable for use in a number of individual cases.

- Matrix device does not allow to print the photo, as well as reproduce any image in a quality manner.

- Unlike more modern installations matrix per unit of time produces much fewer printed sheets of paper... Of course, if you start the device to print the same type of files, then the speed of work can be many times higher than analogs. In addition, the technique provides a mode that allows you to slightly increase the speed of printing, but in this case the quality suffers.

- The device is quite noisy... Since the overwhelming majority of elements perform their work mechanically, the equipment has an increased level of noise emission. In order to eliminate the sound, users have to buy a special enclosure or place the printer in another room.

Today, matrix office equipment is considered one of the oldest printing installations. The technology has been revised many times, the principle of operation has undergone changes, nevertheless, the mechanical part still remains at its original level.

At the same time, this also led to a significant advantage that distinguishes matrix systems - the price for such models covers all their shortcomings.

Species overview

Dot matrix printers come in line matrix and dot matrix printers. These devices are characterized by a different level of noise emission, a period of continuous operation, as well as a speed of operation. From a technical point of view, the differences are reduced to the difference in the scheme of the steam generator and the techniques of its movement.

Dot Matrix

We have already outlined the features of the functioning of a dot matrix printer - dots are fixed with special needles through toner... It only remains to add that the SG of such a device moves from one end to the other due to an electric drive equipped with special positioning sensors. This design allows you to correctly determine the location of the dots, as well as enter color printing (of course, only with a special cartridge with multi-colored toners).

The speed of printing on dot matrix devices is relatively low and directly depends on the total number of needles in the PG - the more of them, the higher the print speed and the better its quality. The most popular these days are the 9- and 24-needle models, they give the functional ratio of speed / quality. Although on sale there are also products with 12, 14, 18, as well as 36 and even 48 needles.

As mentioned above, an increase in the number of PG needles gives an increase in the speed and an increase in the brightness of text reproduction. This difference is especially visible if the number of needles is more than doubled. Let's say An 18-pin model will print much faster than a 9-pin device, but the difference in legibility will be almost imperceptible.... But if you compare the prints made on the 9-pin and 24-pin devices, the differences will be striking.

However, as practice shows, improving the quality is by no means always critical for the user, therefore, for household use or a production device of the starting level, people more often purchase 9-pin devices, especially since they cost an order of magnitude cheaper. A for more time-consuming tasks, they prefer 24-pins or buy linear models.

Linear Matrix

These printers are installed at large firms, where requirements for resistance to increased loads are imposed on office equipment. Such devices are relevant wherever printing is performed 24/7.

Linear matrix mechanisms are characterized by increased performance, ease of use and maximum efficiency. They enable users to efficiently spend their working time and reduce production costs for the purchase of consumables.

In addition, the owners of linear equipment are much less likely to contact service for repairs.

At manufacturing enterprises, the decisive criterion when choosing a matrix printer model is traditionally the ratio of practicality and cost of operating equipment, while the total cost of ownership directly depends on the price of spare parts and consumables, as well as the funds spent on repairs. Linear devices are characterized by a reliable design and have rather inexpensive consumables, therefore, they are cheaper than dot matrix installations and modern laser models.... Thus, the linear matrix mechanism is beneficial in that it provides maximum cost savings with increased print volumes.

A shuttle is used instead of the standard moving SG in linear installations. It is a modular design with small print hammers that can span a whole page in width. During the printing of the text, the block with hammers moves rather quickly from one edge of the sheet to the other.

If, in point-matrix models, the SG moves along the sheet, then the shuttle blocks move a short distance corresponding to the magnitude of the discrepancy between the functional hammers.As a result, they form the entire chain of points in full - after that, the sheet is fed slightly forward and a set of another line is started. That's why the speed of printing linear mechanisms is measured not in characters per second, but in lines per second.

The shuttle of the line matrix device is subject to wear much more slowly than the SG of point devices, since it does not move by itself, but only its separate fragment, while the amplitude of movement is relatively small. The toner cartridge is also economical, since the tape is located at a slight angle to the hammers, and its surface is subject to wear as evenly as possible.

In addition, linear matrix mechanisms, as a rule, have advanced administration functions - most of them can be connected to the company's office network, as well as combined into separate groups to organize a single remote control. Linear matrix mechanisms are made for large companies, so they have good potential for upgrading. So, you can bring a roll and sheet-fed automatic feeder, a paper stacker, as well as a feed mechanism to make copies of printing. It is possible to connect a memory card and pedestal with modules for additional sheets.

Some modern line matrix printers provide interface cards for wireless connectivity... With such a rich variety of existing add-ons, each user can always choose an effective configuration for himself.

Print quality levels

Any technology of operation of printers invariably puts users before the choice between the quality of the device and the speed of printing. Based on these parameters, 3 levels of device quality are distinguished:

- LQ - provides an increase in the quality of the printed text through the use of printers with 24 needles;

- NLQ -Gives average print quality, works on 9-pin devices in 2 approaches;

- Draft –Causes extremely high print speed, but in a draft version.

Medium to high print quality is usually built-in, with draft most often available as an option.

At the same time, 24-pin models can support all modes, so each owner of the equipment independently chooses the format of work that he needs in a given situation.

Popular brands

The undoubted leaders in the segment of office equipment, including in the production of dot matrix printers, are Lexmark, HP, as well as Kyocera, Panasonic, Samsung and the aforementioned Epson company... At the same time, some manufacturers are striving to capture a very specific market segment. For example, the manufacturer Kyocera focuses only on the most discerning consumer, offering elite products designed for long-term use.

Samsung and Epson are both station wagons, although they often have their own unique concepts. So, Epson introduces wireless communication technologies everywhere and provides the most modern solutions in terms of the implementation of control systems, therefore such products are especially appreciated by those consumers who are looking for the optimal combination of functionality and well-thought-out ergonomics in printers.

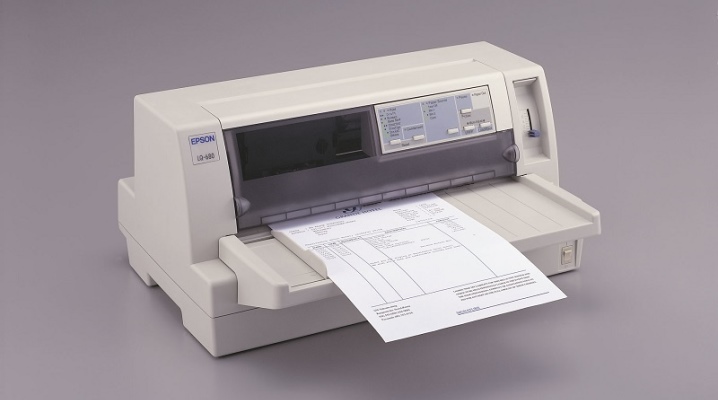

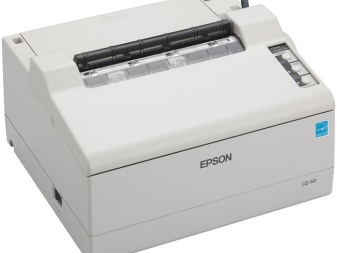

Epson LQ-50 is the most popular among Epson devices.... This is a 24-needle, 50-column printer. It is distinguished by its compact size and exceptional speed, which averages 360 characters per second in high quality mode. The printer is focused on streaming multilayer printing with a one-time output of 3 layers, it can be used with carriers of colored paper of the most different density - from 0.065 to 0.250 mm. Allows you to print on paper of various sizes not exceeding A4.

At the heart of this printer is state-of-the-art Energy Star technology, which allows you to reduce energy costs both during printing and when the equipment is idle.Due to its small size, this printer can be used as a stationary device even in cars, but in this case it will require an adapter to be installed in advance. The system supports Windows and has several printing modes.

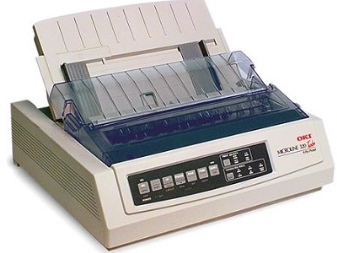

OKI printers - Microline and Microline MX are in high demand... They give a high print speed of up to 2000 characters per minute without pauses or stops. The design of such devices fully complies with the requirement of continuous operation and implies minimal human involvement.

This feature is especially in demand in large computing centers where there is a need for automatic output of files to print.

Selection Tips

When buying a dot matrix printer, first of all it is necessary to take into account the peculiarities of its use... So, for bank printing, printing receipts and various tickets, as well as making multiple copies from the printer, the minimum cost of printing is required in combination with high speed. Dot matrix 9-pin devices fully satisfy these criteria.

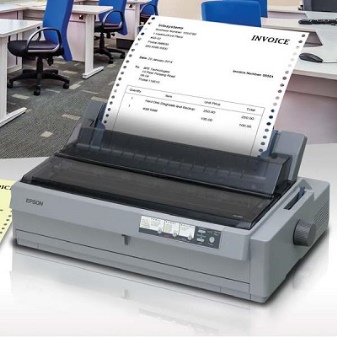

For printouts of financial statements, business cards, labels and all kinds of logistic documents, such characteristics as increased print resolution, good font rendering and clear reproduction of small text are necessary. In this case, pay attention to the dot matrix model with 24 needles.

For streaming printing in office premises, as well as for the constant output of documents from computer systems, the printer must be productive, reliable and resistant to increased daily workloads. In such a situation, linear matrix models are recommended.

In the next video, you will find a detailed review of the Epson LQ-100 24-pin dot matrix printer.

The comment was sent successfully.