What is a Cutting Plotter and How to Choose One?

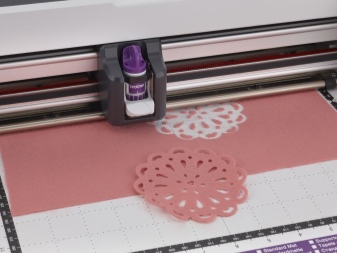

Cutting plotter - a device for cutting images according to the specified parameters. Posters, signs, stickers, postcards, patterns - these are not all products that can be made using plotters. Such a device is used not only in business, but it can also be useful at home if you are doing, for example, scrapbooking or decorating fabrics.

What it is?

Plotters are devices used for printing on large-sized paper sheets of various poster products, billboards, drawings and much more.... But their functionality is much more extensive. They can work with wood, vinyl, textiles, and other materials. Of course, the price for them is high, which is why they can be seen at large enterprises.

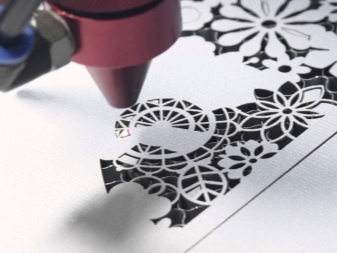

Cutting plotter (cutter) is designed for accurate cutting of simple and complex images made of paper, cardboard, film, plastic material. Moreover, the source code can be presented both in sheet and in roll form.

There are machines that combine two types of operations - printing and cutting.

How does it work?

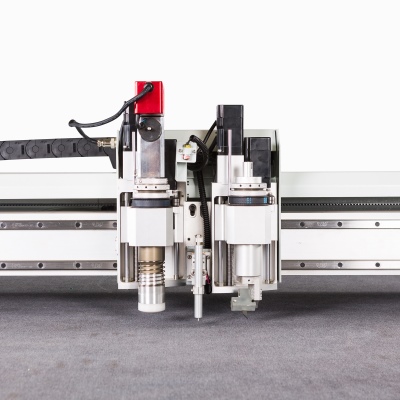

Cutter - a special device with raw material placed on it in a roll form or with a special table for unfolding and fixing sheet raw materials. The main function of the device - cutting letters, images, patterns on the source. As a working tool, a special knife is used, fixed above the table in a moving carriage, which is the principle of operation of the device. Structurally, there are several types of knives.

- Tangential - used for processing materials up to 3 mm thick. The apparatus is capable of cutting and notching figures of relatively simple configurations. Usually equipped with an additional drive with software. The device fixes short stops before the next turn of the cutter (the blade is removed from the source, turned and lowered again).

- Oscillating - it is used for cutting both simple and complex configurations from cardboard, foam and other things up to 3 cm thick. The device works like a jigsaw, producing cutting movements in a reciprocating mode.

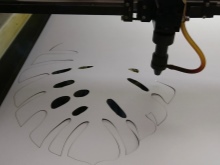

- Vane - it is used to perform cutting of complex curly contours. In this version, the knife makes a rotational movement in a special head. All curly turns of the knife are made directly in the material.

Before starting the operation, a file with the image and the order of movement of the cutter is installed in the device, and then adjustment measures are taken to select the depth of cut and pressure of the cutter.

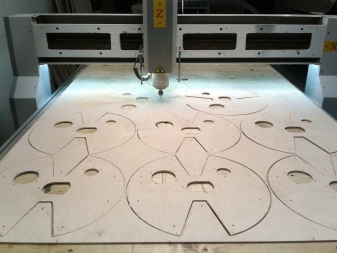

CNC cutters can function with a range of relatively hard textures: leather, felt, felt, cardboard, parchment, foil, polystyrene foam, polyurethane foam. Powerful machines with high torch pressures can cut thin plywood or acrylic, but the cutting edge quickly becomes dull.

A high degree of accuracy and high-speed qualities of PU devices ensure the applicability of cutters in a wide variety of areas:

- in advertising and printing;

- in the clothing, footwear and glass industries (cutting patterns, preparing templates);

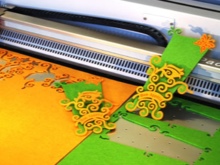

- in the textile industry for the production of drawings and inscriptions from thermofilm;

- in various types of needlework, for example, scrapbooking, making felt crafts and others;

- for the manufacture of packaging products.

Well-known firms for the manufacture of CNC plotter devices are:

- Silhouette (USA);

- Graphtec (Japan);

- Brother (Japan);

- GCC (Taiwan).

Species overview

One of the principles of classification of plotters is their functionality (appointment). Accordingly, plotters are divided into cutting and printing devices, that is, performing either one or the other function.

However, devices are also produced that combine both functions - hybrid plotters... Such devices are executed in one body. For example, in the initial pass, the hybrid can print on self-adhesive material, and in the second, cut the roll into products of specified sizes and shapes.

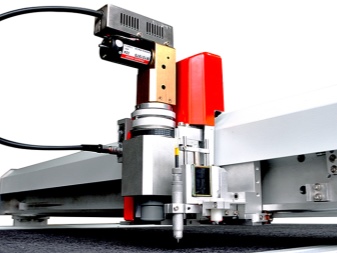

By design, plotters are divided into:

- laser;

- flat (tablet);

- roll.

Laser devices work on a principle similar to that of a printer. In fact, this is a laser MFP, which is based on electrography, using electrostatic fields and the properties of light-sensitive semiconductor elements, including selenium. In flat laser cutters, a laser operates instead of a moving carriage with a fixed cutter.

Cutters are divided according to the methods of supplying materials into 2 types: tablet and roll.

Tablet

Here after fixing the sheet to the desktop the process of cutting raw materials is carried out by a movable carriage with a knifemoving along a given trajectory. The head performing the cutting process can move in different directions. Some models are equipped with special holders that allow using roll options in work.

The sheets are fixed on the table with double-sided tape or with the help of a specially equipped vacuum device. The size of the plotter working platform can be up to 2 meters. Plates are versatile and allow you to work with materials of any format. Powerful models even cut plexiglass. In professional devices, both a cutter and a laser can be mounted on the carriage.

Roll

In roll-fed installations the head moves in different directions, cutting out figures according to the stencil in the process of synchronous filing of the source. The quality of such a product is higher, since there is a possibility of more accurate processing of small elements.

The specified type of cutters cuts materials installed in the form of rolls (vinyl films, fabrics, etc.). The sources are fixed here using special pressure rollers, and the cutting carriage has only one degree of freedom and moves across the unfolding surface. Longitudinal operations are carried out with the help of a coinciding counter feed of material. In order to avoid distortions, the material is placed according to the established marks located on the body of the device. The width of the cut depends on the product model and can vary from A3 to 1920 cm.

Roll-up installations are more suitable for large enterprises and work with a significant amount of material.

Various models are produced for household needs: desktop (mini-plotter), manual, home and other varieties. Optical positioning cutters acquired in cases where greater cutting accuracy is required.

Rating of the best models

Experts distinguish a number of models among the most high-quality and convenient products.

1. Cutter PCut SC-630:

- cutting width - 730/635 mm;

- pressure on the cutter - up to 800 g;

- motor - microstepping;

- cutting speed - 600 mm / s;

- number of pressure rollers - 3;

- USB, Serial (RS232C), SD Card interface;

- memory - 4 MB.

Practical LCD panel for quick set-up. Torch pressure is used to cut dense materials such as magnetic vinyl. The device is equipped with a marking point positioning device. Complete with software (WinPCsign) and drivers for cutting directly from CorelDRAW software.

2. Professional cutter Graphtec CE5000-60 (Japan):

- roll width - 712 mm;

- cutting speed - up to 600 mm / s;

- 2 positions in the installation of pressure rollers;

- pressure on the cutter - up to 300 g.

The unit perfectly handles sharp corners and small elements, it is equipped with servo drives, which guarantees the correct cut.It is possible to work with layouts of considerable size, while maintaining the required degree of accuracy.

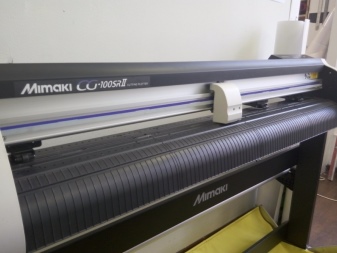

3. Cutter-plotter Mimaki CG-100 SRII:

- cutting width - 1250/1070 mm;

- pressure on the cutter - up to 400 g;

- servo motor;

- cutting speed - 850 mm / s;

- USB and RS232C interface;

- memory - 30 MB.

It can work with various types of films, fabrics and cardboard. It has a torch control function and an optical marking device. FineCut 7 software is a plug-in for CorelDRAW and Adobe Illustrator CS 3 / CS.

4. Desktop cutter Roland GX-24:

- cutting width - 700/584 mm;

- pressure on the cutter - 250 g;

- servo motor;

- cutting speed - 500 mm / s.

Works with a wide variety of materials - vinyl, reflective, thermal transfer and sandblast films. Has the function of leveling curves, which increases the accuracy of the cut at high speeds. The optical corrector works automatically. The cutter offset is manually set to facilitate working with small fonts. LCD panel, convenient service and quality work. Gives photorealistic images.

5. Cutter Vicsign VS 630:

- cutting width - 730/635 mm.

- motor - microstepping;

- cutting speed - 650 mm / s;

- pressure on the cutter - up to 1000 g;

- memory - 8 MB.

Excellent cutting quality. Functions according to the assigned template without a PC.

Thus, depending on the indicators, the 1st place will be Mimaki CG-100 SRII; 2nd - Chinese PCut SC-630; 3rd - Japanese Graphtec CE5000-60.

How to choose?

The choice of the cutter is made for targeted reasons, that is, for what and how the device will be used. The format of the final product is also taken into account - A4, A3 or other options. The main characteristics are also relevant:

- raw material format;

- the level of cutting accuracy;

- torch pressure;

- cutting speed.

The width of the processed materials is usually limited to 100 cm, this size is quite enough for the production of most types of advertising products, although sometimes there is a need to use more wide-format cutters. Nevertheless, practice shows that cutters with working dimensions of 50-72 cm are most often used, including for the home.

The next relevant parameter is cutting precision. If it becomes necessary to cut out small fragments, then a cutter with high accuracy is needed. Of course, this affects the price of the product.

The optical positioning function is provided in the device special sensorsallowing you to find optical points within ready-made layouts. This allows you to get a product of any degree of complexity. For example, in the production of stickers, if a roll with a circulation to be cut is installed in the machine, the cutter needs to be “attached” to the given coordinates at certain points. Only in this way will he be able to give out complex contours in the most accurate way, correctly copying all the curves of the prepared drawing.

Knife pressure - an indicator that is especially important for choosing a cutter. It determines the degree of density of the material that the device is capable of processing. So, if you plan to make clippings from photographic paper, film, then a pressure of 350 g will be enough, but for magnetic vinyl this will not be enough. The value of the parameter here should be at least 400-500 g. Often its value is adjusted by being displayed on the display.

Cut speed determines the performance of the apparatus. At the same time, its greatest value is relevant without losing the quality of the result. If you do not have this need, it makes sense to choose a slower device. Saving money is not the last thing in the acquisition of such equipment.

The cutters in the cutter are driven either by a stepper motor or by a servo motor. In the first (mechanical) version, the torch moves in steps. It is a time-tested technology that demonstrates stability and relative quality. Plus, it's inexpensive. However, such motors are noisy and do not provide high-precision performance.In other words, this option is not entirely suitable for obtaining a cut with smooth curves.

For this reason, to complete complex tasks, digital servo cutters, which set the device holder in motion using an encoder that receives commands from a computer. Cutters with a servo motor are capable of cutting both large-sized parts and small figures (3 mm). At the same time, the accuracy of execution is not lost even with the release of significant volumes.

It is useful to remember both software and technology compatibility.... Thus, a number of Japanese devices are integrated with well-known graphic editors, for example, with CorelDRAW. The Chinese prefer their own software.

A number of additional elements to the cutter should be mentioned here: LCD displays, roll holders, network indicators, cross cutter, material containers, toolboxes and other items.

How to use?

The quality of the cutters, regardless of how you use it - for cardboard, for fabric, for scrapbooking, for patterns and others - depends on the following aspects:

- sharpness of the cutting edge of the knife, which is especially important when performing small jobs with high precision;

- the quality of the original drawing;

- adhesion properties of the substrate, which fixes the working materials;

- error-free setting of the device for specific consumables.

Before starting work, the device is connected to a computer on which the corresponding software is already installed. The program sends the image for cutting to the cutter, then the cutting tool comes into action.

The most popular software is CorelDRAW, a well-known vector editor designed specifically for processing graphic documents and composing images. In addition to this program, a number of tools have been developed that work with plotters.

- SignCut - paid software with preview, which has a number of free plugins for famous design developments.

- PlotCalc - Software with a simple and intuitive interface.

- Omega cut - multifunctional software for working with project documents. Here, for example, you can scan and perform other actions.

For hybrid devices, as a rule, use the proprietary software from the manufacturer, which is included with the plotters. It greatly expands the capabilities of the device, reducing the likelihood of errors.

The plotter setting is performed according to the algorithm.

- To begin with, a CD with software is inserted into the PC. If there is no such disk, then the necessary files with drivers and instructions are downloaded from the website of the manufacturer of the device.

- We install the software on the computer and connect the device.

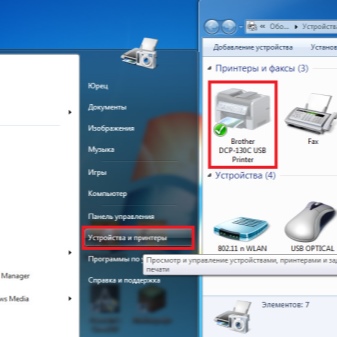

- In the "Start" menu we find the "Devices" section. When new hardware is found, the system will show it in the "Printers and Faxes" column. Double-click on the plotter image.

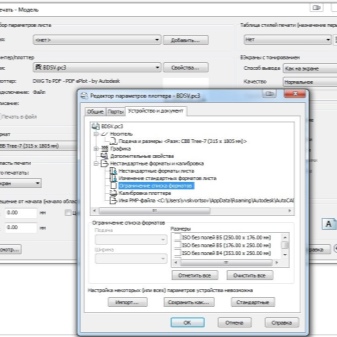

- We configure the parameters of the machine's operation - the type of media and the way it is fed, paper size, print area and other values.

The preparation procedure for all plotters is almost identical.

- Preparation of the required image, drawing in any vector program or in the basic software supplied with the device (many programs have a ready-made image import).

- Preparation of material for cutting. It is important to carefully place the edges of the roll or base sheet into the device, and securely fix the pressure rollers. Using the test, set the correct knife pressure so that the cutting of the material is accurate and does not damage the substrate. Next, we set up the cutting area. Now we set the starting position of the knife, send the file for cutting from the computer.

- At the end of the work, it remains to remove the excess parts of the finished image, then apply the mounting film on its surface (if necessary). Mounting tape is necessary to transfer the pattern to the surface, preserving all the elements of the image.

- The cleanliness of the device also plays an important role in working with the cutter.For cleaning, use a detergent, and then treat with a technical solvent corresponding to the surface. At the end of cleaning, everything should be wiped dry.

For an overview of the Cricut Explore cutting plotter, see the following video.

The comment was sent successfully.