Heated towel rails with side connection

It's no secret that the bathroom differs from the rest by the large accumulation of moisture inside. A heated towel rail is a great and inexpensive option for making a room drier. Such a device allows you to quickly dry the towel, hence the name, and also contributes to a favorable climate inside.

Advantages and disadvantages

Towel rails with side connection allow you to make not only a direct tie-in, but also to use additional fittings. With this design, it is imperative to make a straight jumper. It makes it possible to use the device without draining and stopping the heating system.

A heated towel rail is often used as an additional source of heating. When choosing the described option, it is useful to know when it is advisable to refer to the side option. As a rule, these are situations:

- when it is required to simplify the connection diagram, and at the same time minimize the number of fittings;

- when communications are located on the side of the wall;

- when it becomes necessary to organize a new open or closed wiring;

- when the bypass system and thermostat are installed;

- in systems where several radiators are connected at once, in parallel or in series - it does not matter;

- with non-standard outlet of communication pipes.

It is worth saying that the side-connected heated towel rail can be used not only in the bathroom. It is a kind of heating radiator, thanks to which it is easy to keep warm in a room or other room. Connect it to both a hot water riser and a heating system.

Of the advantages of this type, it should be noted:

- walls are not damaged;

- you can put the device both before the start and after the completion of finishing work;

- the structure is mounted to the main riser;

- there is no need to install an additional pipe system.

The only drawback worth talking about is that the heated towel rail is made using welding. The service life of the model depends on how well the welded seams are made.

This detail should be given special attention when buying, so that later you do not face big problems if you break through a pipe with boiling water.

Views by side connection method

Heated towel rails with side connection can be water or electric, with left and right connections. All this makes it possible to install the device in almost any room, taking into account its design features. There are also vertical and horizontal options.

The side outlet opens up great possibilities for the user. The connection becomes available to both hidden and open wiring.

When using hot water, it is possible to save energy, while drying towels is carried out quickly, even in the absence of a heating season.

Dimensions and design

All models on the modern market are divided depending on a number of parameters:

- by area;

- taking into account the heat capacity;

- by design and format;

- by the material used in the manufacture of the heated towel rail.

Many experts say that heated towel rails are a standardized product, and in the manufacture of one standard size of the distance between the elements, but today everything is different.

In search of new ideas and suggestions for customers, most manufacturers began to produce non-standard models.

As for the heat capacity, pipes with different diameters are used in the production process of heated towel rails. These are elements with a diameter of 32 cm, 40 cm and sometimes even 50 and 60 cm. You can combine pipes of different diameters, while the user gets unlimited possibilities when decorating the room.

Design and format have played a big role lately. People stopped choosing classic designs. On store shelves, it is easy to find a curved heated towel rail in a classic version or a complex structure model.

Thanks to the use of pipes of various cross-sections, new original versions of heated towel rails have appeared. Thanks to such products, the interior in the bathtub is easy to complement or add zest to it.

As for the material of manufacture, foreign manufacturers offer products made of brass and bronze. These are the metals that are most commonly used. But it should be understood that in conditions when hard water flows in the tap, such models quickly collapse, therefore they do not have a long service life.

For our country, it is advised to choose heated towel rails made of stainless or black steel. It is they who have proven their practicality over time, regardless of the operating conditions.

There is another point that must be taken into account. The coolant in a centralized system is supplied under high pressure, which is why the flow area of the product plays an important role. The larger it is, the less pressure acts on the metal from the inside, otherwise you may encounter a water hammer and subsequently with the need for serious repairs.

For small bathrooms, models with a width of 30 cm are suitable. It can be either black or white, possibly metallic. Recently, options for 600x600 mm, 500x400 mm began to be bought up more. There are even models with a shelf. When buying, it is worth paying attention to other parameters, for example, the center distance, the type of coverage.

Top Models

The bathroom fixtures market offers the buyer a rating of the best heated towel rails, including classic options and improved ones.

In fact, the format plays an important role. "Snake" and the classic are the most common, but even in such variants, you can find many differences. They consist in:

- dimensions;

- distance between elements;

- wing size;

- the number of bends available.

"Ladder"

If we consider from the side of popularity, then this is the second, most often acquired type of heated towel rail. This design has a lot of advantages, including ease of placement, many elements that give off heat to the room. The efficiency of such a device is at a high level.

Products are available in various sizes on the market. There are both small and giant ones.

M-shaped

The name of such models stands for “minimal coil”. This is because they have a small volume of the coolant, and therefore the heat capacity is at a low level. Manufacturers have worked on the design and format, making it easy to fit heated towel rails of the described category into any interior.

U-shaped

The low price is typical for heated towel rails of this group. This is a good and economical solution for a small area.

Other

There are other options, for example, combined and individual design solutions. The latter are not often found side-connected, but they are still found.

The consumer has the opportunity to choose a model that is lyre-shaped, round, with beams and even with movable elements. Such options are more expensive because they have a non-standard look.

You should always remember that a custom solution may not be so easy to connect. The level of practicality of the models of this class is lower than that of the rest. If you stop your choice on such equipment, then you should first consult with a plumber. It is he who can soberly assess whether the installation of the product is possible in real conditions.

The premium category includes sophisticated designs. It is better to use such heated towel rails on large areas. They usually have more than 20 sections, so the product is also suitable for drying things.

Installation tips

To properly connect a heated towel rail, you must first draw up a diagram. It is allowed to make connections to the heating system in several versions.

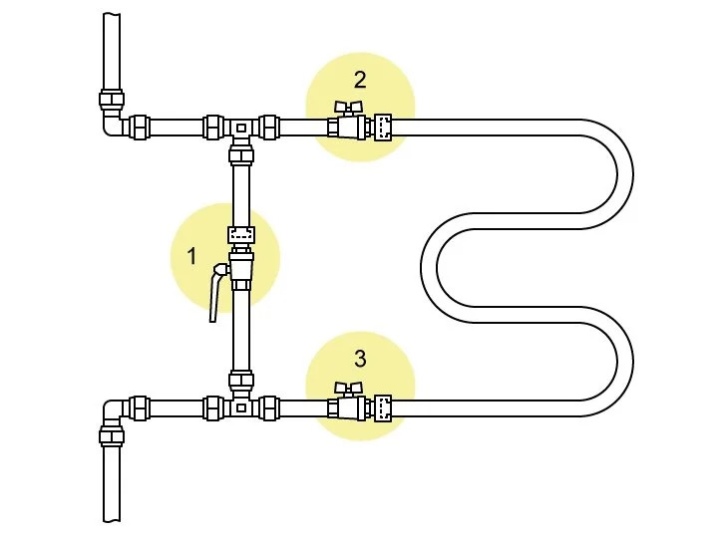

Direct connection

The advantage of this method is that there is no large number of fittings. Ball valves are at the inlet and outlet. If suddenly an emergency arises, then they can be quickly and easily blocked.

There is also a significant disadvantage to the method used - it will not be possible to adjust the temperature. As soon as the valve closes, the movement of the coolant stops.

Therefore, it is better to use the method when there is an autonomous system or you want to reduce the cost of the installation process.

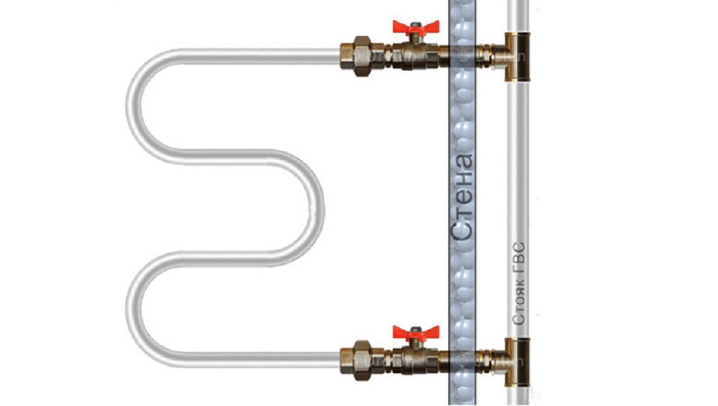

Bypass channel

It is also called bypass. With the installation of a heated towel rail, a jumper with fittings is also organized in parallel. Cranes are used for adjustment and shutdown. Additionally, a crane is installed, except for those that are at the entrance and exit. It allows you to regulate the heating.

If the product is of a complex design, it can be connected from different sides, while the heat transfer changes. That is why each individual case is advised to be considered individually.

Lateral connection will be effective if several conditions are met. The slope of the branches is at least 3 millimeters per 1 meter, the heated towel rail is mounted above the return circuit and there are no loops on the inlets.

The diagonal connection is considered optimal, while it is best to bring it to the upper corner. The water that has cooled down leaves through the lower near corner. This trajectory excludes the appearance of stagnant zones.

If during installation the bypass was narrowed or displaced, then there is a possibility that the flow will stop. The fluid stops moving at the very moment when the pressure in the system equals with the pressure, which is called gravitational. It occurs when there is a difference in the density of liquids and their temperatures.

Understated loop section and long piping are the main reasons. You can correct the situation - for this you will need to move the heated towel rail closer to the highway or remove narrowed areas in the system.

If a plastic product is used, then the likelihood of encountering such a problem is less.

The side connection can be simple, through corners or back:

- in the first case, a union nut or external thread is used - this is ideal for an open gasket;

- uniform heating can be achieved with a corner joint;

- if the track is hidden behind the finish, then the latter option should be used.

When the branch is welded directly to the riser, the bypass is considered to be part of it. That is why such work is better done by a specialist, since rash actions can lead to serious problems in the future. Plumbers often point out the fact that with such a connection, water passes by the heated towel rail. It is possible to solve the problem with a gravity pump. When the water cools down, it goes down and pushes hot water up.

To connect a heated towel rail with a bypass that is not offset or narrowed, certain conditions must be met:

- the supply drain must be located above the point where the heated towel rail is connected;

- the return riser is below the connection point;

- the connection pipes are at an inclination of at least 3 millimeters;

- the pipe should not sag and must be exactly in size;

- the diameter of the pipe that is responsible for the connection is at least 25 millimeters.

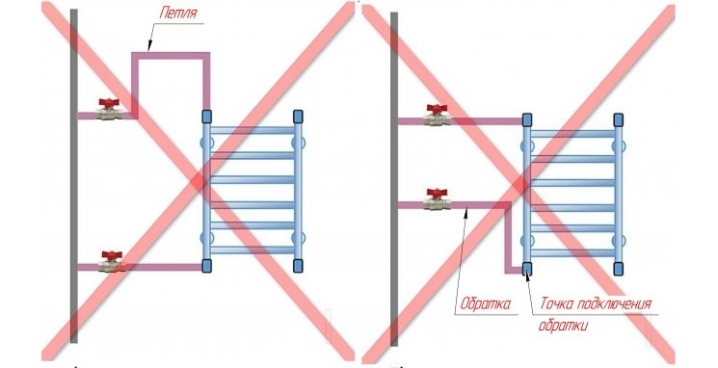

Under no circumstances should shut-off valves be installed on the bypass.When the bypass is narrowed but not biased, the system will not function properly. This is the main reason why the element always stays cold. It is worth considering only the top feed.

Any professional plumber will tell you that the problem with a heated towel rail is always an installation error. Although the side connection scheme is considered optimal, you can mess things up with it if you do not know all the subtleties.

Among the main mistakes:

- the bottom point of the product is ultimately located below where the return outlet is located;

- arched or protruding shape at the top bend.

In the first case, the installed element heats up only for a while. When the water reaches the bottom outlet, its further movement is impossible. 100% in the pipe can be found when studying the dirt that gets there from the riser. The result is deformation of the material inside and a quick failure. In the second version, the accumulation of air in the pipes, the impossibility of subsequent operation. An additional drain valve will be required.

The comment was sent successfully.