What is infrared film and how to connect it?

Infrared material has many benefits. It is used to improve comfort and optimal indoor temperatures. This device is offered in different variations, so first it is important to analyze the technical data of the material, as well as to get acquainted with the leading manufacturers. To make insulation, you need to follow step-by-step instructions, and you can cope with the solution of the problem yourself. In this article, we will take a closer look at what infrared film is and how to connect it.

What it is?

There are many modern materials on the market that fulfill the task of heating elements. One of them is infrared film, which is capable of emitting heat. This device consists of three layers, each of which performs its own task. It is worth noting that the film can be used not only for local heating, but also to equip the whole house with it. As for the principle of operation, it consists in the radiation of infrared long waves, which heats up hard surfaces that are in the entire room, due to which the air heats up, so the temperature will be optimal and you can create comfortable conditions for living and working.

Important! The human body perceives infrared radiation as solar heat, so if you need a heating system, you can safely choose such a film.

She works great and does her job well. Such heating products are in great demand, as they have a number of advantages.

Advantages and disadvantages

Thanks to such a simple material, everyone can handle the installation, besides, the process does not take much time, which means that the installation of heating can be done quickly. One of the main advantages is the absence of the need to make a screed. The film coating can be combined with different types of floors, be it tiles, laminate and so on. This will not affect the height of the room, and this is true for oversized rooms where there is little space.

The material is reliable, contributes to energy savings when compared with other types of heating systems. Self-regulating function is provided by installing a dedicated regulator.

It should be noted that such an IR film can eliminate unpleasant odors, the air humidity remains at the same level. In addition, the material does not cause allergic reactions due to its environmental friendliness. When heated, anions are born, which have a positive effect on the human body.

As for the disadvantages, but they are still there, the film runs on electricity, so there may be voltage surges at home, but this problem can be dealt with by installing a stabilizer and a protective relay. Also, the material is not cheap, so you have to invest in order to get high-quality heating of the room. Thus, the advantages of IR coverage are much greater than the disadvantages, so you can safely consider this option for heating a room.

Species overview

Despite the fact that all IR films have a common principle of operation and characteristics, they are divided into several varieties that should be studied before purchasing. The difference lies in maximum heating performance and compatibility with the flooring material. High-temperature underfloor heating that is installed under the tiles. The maximum heating rate reaches +50 degrees Celsius, so the material is not used together with linoleum or laminate. As for the low-temperature IR material, the system does not exceed +27 degrees Celsius, so it can be used with different coatings. On the market, you can also find a versatile system that is suitable for installation in different conditions and can be combined with both tiles and linoleum.

However, there are other parameters that divide the IR film into types depending on the heating component. - carbon, bimetallic, and they need to be studied in more detail. The power indicator of the material is an important characteristic that you need to pay attention to first. The power of films can be different, and this should be taken into account when choosing the type of material, because this will affect the quality of heating and other factors.

Carbon films are considered the most expensive. This heating element is made of carbon material, the structure of which is fibrous. Some manufacturers provide films with a protective layer using graphite. Thanks to this spraying, the strength of the system increases, which in turn extends the service life of the heating material.

The difference between the bimetallic film is that the heating element consists of aluminum and copper interlayers. For the manufacture of the base, polyurethane is used, due to which the material becomes flexible and pliable, which means that it is easier to work with it. However, this heating is not suitable for rooms with ceramic hob. This is a low temperature film that cannot be heated above +27 degrees Celsius.

All heating systems have a thermostat to monitor temperature readings and set optimal heating.

Famous manufacturers

There is a wide selection of manufacturers on the market for modern heating materials. Before buying an IR film, it is useful to study the characteristics of the products of a particular company in order to analyze the information and compare the benefits.

- One of the domestic manufacturers is firm "Zebra", which has been producing film type heaters for many years. In the assortment, you can find different cutting sections, which allows you to select the required material parameters. It is worth noting that the kit includes the necessary equipment with which you can independently perform the installation.

- South Korean company Caleo can also offer a wide variety of IR films at an affordable price. However, its products are fragile and can deform in poor conditions, so you should be careful when handling the material. The infrared film has a thickness of 0.4 cm, and the power varies from 180 to 220 watts.

- If a material with a higher heating power is required, then study Rexva products, which is presented in rolls of different widths. The design uses an anti-spark mesh, which makes the film more reliable and resistant to mechanical damage.

- When buying such an expensive material, you want to get a warranty from the manufacturer, and Heat Plus company provides it. In the assortment you can find IR films of different parameters with a detailed description.

Selection Tips

The film floor system must be chosen carefully, so it is important to pay attention to all the factors that affect the quality of heating the room. First, you need to calculate how much material needs to be purchased to equip a certain area. If we talk about the percentage, it depends on whether the IR film will be the only equipment for heating or as an auxiliary element.

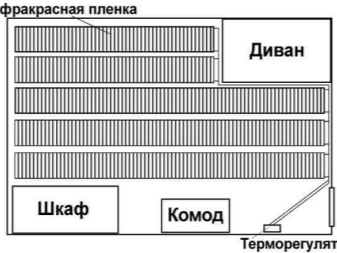

In the first case, it will be required that the material fill about 80% of the area, and as an addition, no more than 50%. To determine the total length of all strips, you can draw a layout diagram on a regular sheet, then analyze the size of each fragment, and put it together.

It is important to note that when laying, the film should recede from the walls by 10–20 cm. The IR system is controlled by a thermostat, which is included in the package with a temperature sensor. You can choose one of the device modifications - mechanical with keys and wheels or electronic with buttons and display.

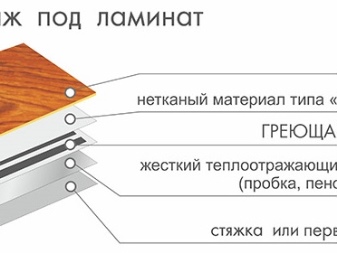

NSWhen choosing such a device, it is necessary to take into account the power of the thermostat, therefore, the indicator must be multiplied by the size of the area that will be covered with a heating element. When installing such a system, you must make sure that the flooring is completely flat, and in order to avoid heat loss, craftsmen most often use heat-reflecting materials.

If you are going to lay the film under the tiles, it is better to use a mounting grid, then the coating will not move.

Application methods and installation rules

To lay the film floor yourself, it is enough to follow the step-by-step instructions and the recommendations of specialists, then the work will be done efficiently, and heating is provided. At the same time, it is important to observe safety measures, which means that before work it is necessary to clean the room of small debris, dust, and, if necessary, cover it with insulation material.

The film strips are placed 5 mm apart, which will ensure the safe operation of such heating. Before work, you need to prepare the necessary tools. Places where the film is cut must be covered with bitumen insulation. The main advantage of connecting this type of heating is that it is suitable for almost any room, be it an apartment, house, greenhouse, sauna, and so on.

For floor

Often, infrared heating film is used for the floor, so you need to figure out how the system is installed. It should be noted that the dismantling of the old concrete pavement is not required, and this greatly facilitates the task. At the same time, it is important to clean the base, if necessary, make repairs, fill up holes and pits so that the surface becomes even. For insulation, you can use foil-clad material that is not an electrical conductor.

Then you need to start marking in order to determine the parameters of the film and cut the material. It remains to position the heating element, fix it with hot glue or tape. The copper strips should be laid down. Recesses are cut into the substrates to accommodate cables, terminals and a thermal sensor. Thermal insulation is carried out using tar pads, which ensure tightness. At the last stage, the wires are connected to the thermostat, and they are attached to the wall.

It is necessary to check the performance of the system, you can lay the flooring, linoleum, laminate and even tiles will do. You can connect the heating with a regulator by setting the desired temperature.

To the ceiling

To heat the room from above, the film is installed on the ceiling. Radiated heat affects surfaces, the air heats up, and it becomes comfortable inside. Installation of such material is carried out under plastic, suspended ceiling and drywall. Here it is necessary, just as with the floor, to determine the area of the site and prepare the film of the required dimensions.

Thermal insulation is fixed on the ceiling surface; dowels and screws are used for this. Then it is necessary to mount the heating film with contact clips. It is important to make sure the connection is secure, then insulate the two sides of the cut. The electrical wire is connected to a ferrule and then a copper bar on both sides. All strips must be connected to the network in parallel through a thermostat. The sensor is fixed with tape under the heating element, then the system can be connected and checked how it works.At the final stage, it remains to install the final ceiling covering and enjoy the comfort.

On the walls

This type of insulation is suitable for saunas and chicken coops, as well as utility rooms where a certain temperature is required. Here the surface is also leveled, waterproofing is installed, and then the film itself is attached. When it comes to equipping a chicken coop, it is necessary to think over where the birds will be located so that only the free space is heated, and not the objects that are in the room. In addition, precautions are taken this way.

Such a system is also great for saunas, where the booth needs to be lined with clapboard or wooden boards, and then fix the film with a construction stapler. Each time, when working with IR material, one should remember about the isolation of the contact junction points. After the work is done, you can operate the premises. It should be emphasized that infrared heating is suitable for different types of premises and has a number of positive characteristics.

The main thing is to choose the right heater according to the power indicators, and follow the installation instructions.

In the next video, you are waiting for the installation, installation and connection of an infrared film floor.

Interesting article.

The comment was sent successfully.