Features and uses of fluoroplastic film

PTFE film is used as an insulating material for the production of power cables and wires. In addition, the film has a wide range of applications in other areas.

What it is?

PTFE film is an extruded polymer material. Fluoroplastic powder is used as a base. A blank is made from it, in professional slang it is called a "pill". The technological process involves careful monitoring of the homogeneity of the material. According to state standards, not the slightest sign of impregnation of foreign substances is allowed.

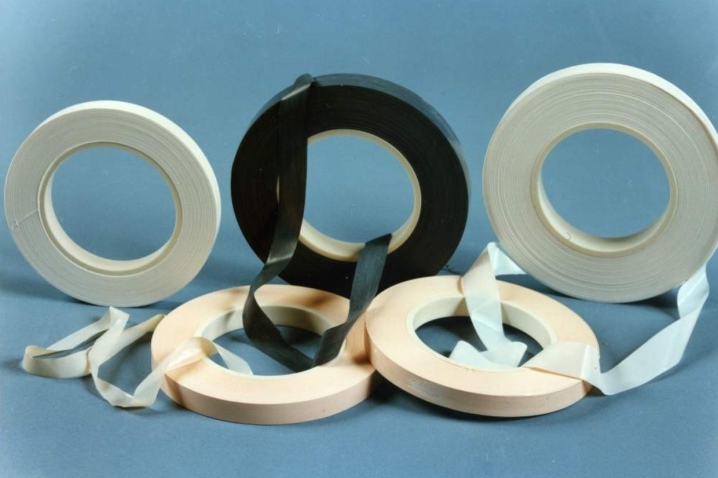

The film has high strength, elasticity and resistance to aggressive environments. In the manufacturing process, the technology of the cold method is used. Wide shavings, similar to long strips, are cut from the blanks and rolled. This reduces the thickness of the belts, gives the material strength in length and width. Then the film is rolled into rolls. A similar method is used to produce fluoroplastic tape.

Views

The consumer buys the film in rolls of various lengths: 50,100, 250 m. The thickness of the fluoroplastic polymer varies from 10 to 500 microns. The technical characteristics of the material do not allow its use in work with fluorine gas, alkaline solutions, chlorine trifluoride and melts. The type of fluoroplastic depends on the original polymer - F-40. F-10, F-50, 2-M, 3-M, etc.

Properties.

- The film is characterized by high strength and reduced reflectivity.

- Resistant to aggressive effects, has the ability to pass gas.

- It can withstand temperatures from - 60 to 250 degrees and can be processed mechanically.

- It adheres perfectly to materials of other physical characteristics, for example: wood, metal, plastic and other surfaces.

- It has thermostatic properties and is resistant to chemical and radiation effects.

Before the finished product arrives at the consumer, it undergoes strict quality control for compliance with GOST - 24222-80 standards. PTFE film can be of 3 types: deep drawing, metallized, welded.

Grades of polymeric fluoroplastic.

- F-10. Protective covers and elastic containers are made from this type.

- F-50. It is used as insulation, corrosion protection, withstands high temperatures and is resistant to aggressive environments.

- F-4 KO. It is used in the production of capacitors operating at low and high temperatures.

- F-4 EO. It is used as an electrical insulating material for the production of cables, electric wires, as well as in the field of high and ultrahigh frequencies.

- F-4 IO. Its scope is intermediate insulation.

- F-PN. Insulating, gasket and sealing material at temperatures of ± 260 degrees.

- F-4 IN - the same as F-4 IO; F-4 EN - the same as F-4 EO.

Short designation.

- KO - use in capacitor production.

- EO; EN - electrical insulation.

- AND ABOUT; IN - insulating material.

- PN - used as gaskets and seals.

The oriented film has the following parameters.

- Width 10 - 100 mm.

- Thickness 0.02 - 0.1 mm.

Non-oriented film.

- Width 40 - 100mm.

- Thickness 0.06 - 0.25 mm.

Applications

- Package. Fluoroplastic polymer is widely used in the industrial packaging of chemicals, pharmaceuticals, food products, various devices and containers.

- Sports industry - windows of tents and windsurf sails are made of polymer.

- In the cable industry the film is used as a winding for wires and cables.

- In the chemical industry a fluoroplastic polymer is used as protection against corrosive environments and atmospheric and radiation effects.

- In the automotive industry the polymer is used as a protection for compensatory membranes, shaped gaskets and O-rings, as well as for the production of emitter shells from it.

- In electronics relays, microphones, sensors are made from polymer.

- In the food industry The rollers and conveyor belts are coated with a polymer film.

- Fuel and energy industry - production of power plants where fluoroplastic is used.

- In the construction industry the polymer is used in the production of roofing, greenhouse, greenhouse coverings.

- Aviation industry uses fluoroplastic film for the manufacture of elastic containers, fuel tanks, insulation for electrical wiring.

Manufacturers

One of the most famous manufacturers of polymeric fluoroplastic is the Novosibirsk plant of fluoroplastic films. The plant offers a wide range of types and types of fluoroplastic tapes and films.

- Adhesive, sticky, oil resistant.

- Oriented - capacitor, insulating, electrical.

- Non-oriented - insulating and insulating.

- Non-oriented fluoroplastic and cushioning tape.

Other manufacturers.

- BBB "Alliance" - Yekaterinburg. Wholesale and retail supplies.

- LLC "MetallPromContinent", Chelyabinsk.

- LLC "Alexandria", Sterlitamak.

- BVB "Alliance Barnaul".

- "Plastpolymer Prom", St. Petersburg.

- LLC "Fluoroplastic products", Belgorod.

- LLC "Research and Production Enterprise" PLASTPOLIMER PLUS "Simferopol.

The following video talks about PTFE wrap.

The comment was sent successfully.