All about polymer concrete

With the development of science and technology, more and more new materials appear on the construction market. One of them is polymer concrete. Today in our article we will look at the main features of this material.

What it is?

Polymer concrete is a relatively new building material that is actively gaining popularity among users. This is primarily due to the large number of positive characteristics that are characteristic of it. The composition of the material (in addition to traditional and familiar sand and crushed stone) includes many additional components that provide such quality properties of polymer concrete as strength, high performance characteristics, decorative effect and many others.

Let's consider in more detail the main advantages of the material.

- Sustainability... Polymer concrete has increased resistance characteristics in relation to various negative environmental influences, for example, excessive moisture, unstable air temperature, chemical aggressive substances, and so on. So, due to the physical and chemical properties of the material, excess water quickly and easily evaporates from its surface. Due to its resistance to unstable temperature conditions, polymer concrete does not crack even after several freezing cycles.

- Possibility of quick and easy recovery. In this respect, we mean the fact that even in the case of mechanical damage, polymer concrete can be quickly and easily restored and, if necessary, corrected its shape. This procedure is performed using a specially designed restoration mixture.

- Strength... Polymer concrete has high strength characteristics. Accordingly, all products that are made from this material have extended performance properties.

- Smooth surface. It should be borne in mind, despite the smooth surface (which does not have any roughness, defects and other shortcomings), it is not slippery. In this regard, polymer concrete can be quickly and easily cleaned of any contamination.

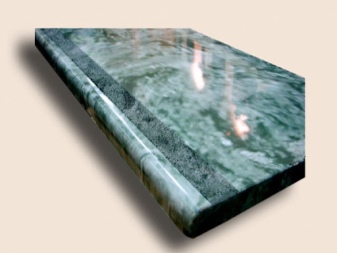

- Variety of colors... Depending on your preferences and needs, you can choose polymer concrete, which resembles marble, granite, malachite and so on in appearance. At the same time, it is rather difficult to distinguish polymer concrete from real stone. Due to this characteristic of the material, it can be used for a variety of purposes. And also polymer concrete will perfectly fit into almost any interior.

- Recyclable. Thus, polymer concrete residues do not pollute the environment. This is primarily due to the fact that the production of the material is waste-free.

At the same time, it should be borne in mind that even despite the presence of such a large number of advantages, polymer concrete is not an ideal material, it also has a number of disadvantages. So, the disadvantages include the following:

- highly flammable;

- relatively high cost (compared to conventional concrete).

The advantages of the material significantly exceed its disadvantages.

It is thanks to this that polymer concrete is widespread, popular and in demand among buyers (both beginners and professional builders).

Composition and properties

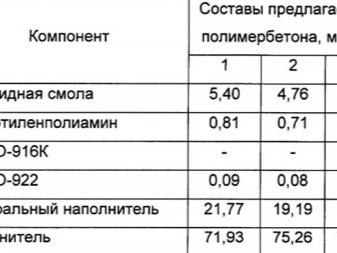

Before purchasing and using polymer concrete, it is important to familiarize yourself in more detail with its composition, as well as its properties and technical characteristics. The composition of the material includes such components as:

- resins (urea-formaldehyde, polyester, epoxy and furfural acetone substances can be used) - this component acts as a binder;

- crushed stone filler (for concrete polymers, the presence of a coarse-grained filler is characteristic, the particles of which can reach an indicator of 4 cm);

- quartz sand (it must be sifted and peeled without fail);

- graphite powder or quartz flour (these elements are used as a filler, which reduces the need for expensive resins);

- plaster of paris (it goes well with urea-formaldehyde resins);

- Surfactant (or surfactants);

- components with antiseptic properties etc.

The distinctive properties of polymer concrete include such characteristics as:

- density - from 300 to 3000 kg per cubic meter;

- specific gravity can range from 500 to 1800 kg per cubic meter;

- abrasion - from 0.02 to 0.03 g per cubic centimeter, and so on.

It can be concluded that polymer concretes are highly durable and are actively used for elastic waterproofing. It is also worth noting the fact that the material is oil and gas resistant.

Classification

In the process of acquiring the material, it should be borne in mind that today there are several types of polymer concrete on the construction market (it can also be called polymer cement or plastic concrete). So, there are several grades of material, their properties and characteristics must comply with generally accepted GOST standards. It is worth noting the fact that the material is classified depending on the concentration of the filler in its composition. Let's consider the main categories.

- The heaviest. The density index of such a material can range from 2500 to 4000 kg. Most often, this material is used for the construction of various load-bearing structures, since it is able to withstand a fairly large mechanical load. The composition of the material includes fractions, the size of which does not exceed 4 cm.

- Medium heavy... The density of such polymer concrete can reach 2500 kg / m³. Cast stones are usually made from it, which imitate an expensive material (for example, marble). The particles of such concrete should not be larger than 2 cm.

- Light... The minimum density of such polymer concrete is 500 kg. In this regard, the material belongs to the structural and thermal insulation category. Lightweight polymer concrete has the ability to save heat.

Cooking technology

- Preparing the necessary components... Before starting the direct preparation of a substance such as a polymer-cement mortar, it is important to take care of the initial preparation of all the necessary substances. So, in this respect, we mean cleaning, sieving and drying all constituent components (resin, sand, and so on).

- Preparation of the mixture... After you have completed the preparatory stage, you can proceed to the direct preparation of the mixture. So, in the mixer you need to put crushed stone, quartz sand and aggregate. These components must be thoroughly mixed together twice (before the second mixing, a little water must be added to the solution). After that, you need to soften the resin (a specially designed solvent is usually used for this), and then add a plasticizer to it and mix everything thoroughly. Next, you need to place the binder with the filler and add the hardener. At the end, the entire mixture must be thoroughly mixed again.

- Fill... To correctly fill, a specially designed lubricating oil or technical petroleum jelly must be applied to the surface of the shape you have chosen. This is necessary so that the solution itself does not stick to the mold. After that, the container must be filled with the composite itself and the surface must be leveled without fail. Next, the solution is compacted on a vibrating platform. In this position, the mixture is kept throughout the day. The finished product can then be safely removed.

How are concrete polymers used?

As mentioned above, concrete polymers are popular and widespread materials that are widely used in various spheres of human life. The following is often made from the material:

- countertops (they have not only practical functional characteristics, for example, hygiene, resistance to mechanical damage, but also an aesthetically pleasing appearance);

- floor coverings (they are quite easy to clean and easy to install, the user does not need to have specific skills, in addition, such coatings will last for a long period of time);

- facade decor (such concrete polymer elements are very popular, as they imitate natural stone);

- monuments and fences (products made of polymer concrete are resistant to negative environmental influences, respectively, they are excellent for making such things) and much more.

In general, there are no restrictions on the use of this material. It can be used to make hardeners, antiseismic devices, self-leveling screed, electrically conductive and conductive PDF, highly filled compositions, drainage systems. At the same time, paint and plaster for outdoor use fit well on the material.

Accordingly, with the help of polymer concretes, it is possible to carry out construction and repairs of any complexity.

Examples of products

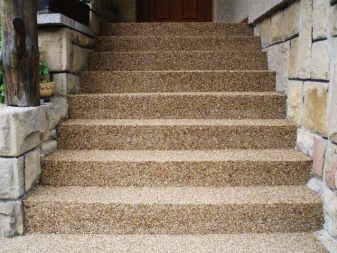

Polymer concrete is used in various spheres of human life for the manufacture of many products: vases, countertops, bathtubs, sinks, sculptures, tiles and putty for the facade, steps, hatches and so on. Artificial stone has high aesthetic and practical qualities. Let's look at a few examples of products.

- These vases are great for decorating and decorating both public and private areas. For example, you can use them to create miniclums.

- The sink made of polymer concrete will be an excellent decoration for both the bathroom and the kitchen. At the same time, you can choose a sink design that will fit well into your overall interior, or a design that will be an accent.

- Tiles made of this material are especially popular among buyers. This is primarily due to a wide variety of colors and tile styles.

- Various fences are often made from polymer concrete, which can be used both inside and outside the house.

- Among other things, you can create a variety of benches and benches from polymer concrete. This way you can decorate your courtyard. In addition, these seating positions are well suited for setting up public spaces (such as parks).

For information on how to make polymer concrete with your own hands, see the next video.

The comment was sent successfully.