All about polyethylene sheet

Polyethylene sheet has a lot of advantages, it is durable, lightweight and cheap. Based on this, it is highly popular in various fields. Let's take a closer look at everything about sheet polyethylene.

Specifications

Polyethylene sheets are produced in strict accordance with regulatory documents that specify how this material is manufactured, transported and stored. At the moment, the most used types are sheets made of high-density polyethylene (LDPE) and low-pressure (HDPE). Separate standards have been developed for these types, GOST 16338-85 for HDPE and 16337-77 for LDPE.

Low-density polyethylene sheets have the following characteristics:

- very high density - more than 0.941 g / cm³;

- excellent frost resistance;

- moisture resistance;

- well tolerates contact with oily and greasy liquids;

- environmentally friendly.

High pressure polyethylene sheets have such basic properties as:

- flexibility and plasticity;

- density 0.900–0.939 g / cm³;

- melting temperature - + 103– + 110 degrees Celsius;

- withstands low temperatures of about minus 120 ° С.

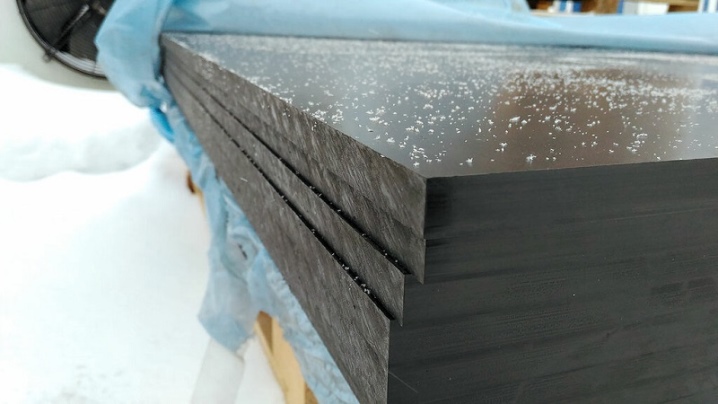

The standards indicate all the parameters for both groups, having studied them, you can familiarize yourself with everything in detail. Both materials do not emit harmful substances and are absolutely harmless to the human body in direct contact with them. And also, when using it, no precautions are needed. You can also find less common - high molecular weight polyethylene. This type of material has increased resistance to mechanical stress, rigidity, reliability and wear resistance. It is able to resist impacts even at minus 200 ° С, begins to melt at + 150 ° С, the density is 0.95 g / cm³.

Views

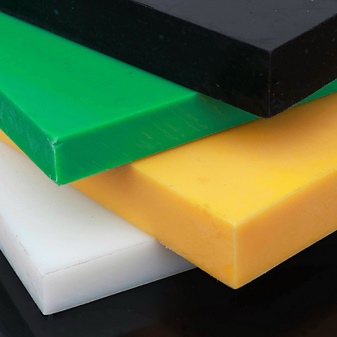

Polyethylene sheet, according to the production method, is classified into groups such as:

- HDPE;

- LDPE;

- high molecular weight polyethylene sheet.

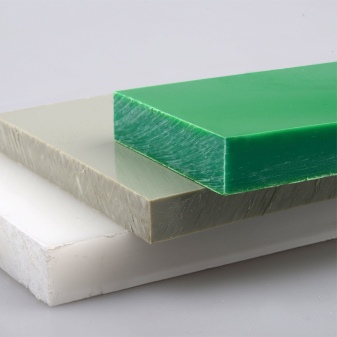

High and low pressure polyethylene is produced by extrusion, and high molecular weight - by pressing. To improve the properties of monolithic polyethylene, in addition to processing raw materials by thermal and mechanical methods, various additives are added. In this way, a so-called "stitched" and "non-stitched" material can be obtained. In the first case, chemical elements are added, a sheet monolithic material with increased strength and temperature performance characteristics is obtained. In the second case, gas is added during melting (isobutane, freon or propane-butane is supplied). The result is a lightweight product with characteristics similar to conventional polyethylene.

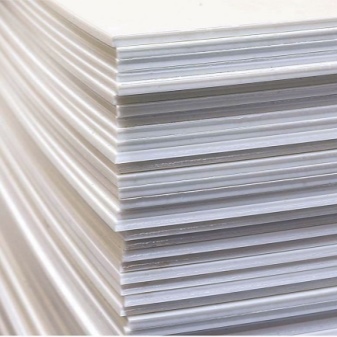

Important! In its pure form, polyethylene is white. Only thin sheets are transparent, and if the thickness increases, it loses transparency.

Stamps

In use (industry and everyday life), HDPE is the most common. Its main brands are PE80, PE100, PE300. PE500 is already high molecular weight and PE1000 is ultra high molecular weight. The temperature regime of operation depends on the marking. For ordinary material, it is possible to use the first three grades at temperatures from -50 to +80, and for high-molecular and ultra-high-molecular from -100 to + 80 degrees Celsius.

Dimensions (edit)

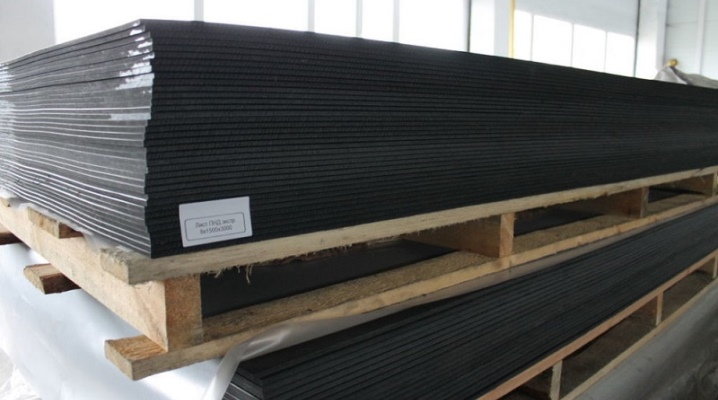

A sheet with dimensions of 1500x3000 mm is considered standard. The thickness is different, from 1 mm. But the most popular are from 3 to 10 mm. Weight varies greatly depending on it. There are a large number of sheets of various thicknesses on sale, consider the parameters of some of them.

Thickness (mm) | Weight (kg) | |

standard sheet | square meter | |

3 | 12,9 | 2,9 |

5 | 21,4 | 4,8 |

6 | 25,7 | 5,7 |

10 | 42,9 | 9,5 |

20 | 85,7 | 19,1 |

25 | 107,1 | 23,8 |

At the request of the customer, it is possible to produce sheets of other sizes, for example, 1000x2000 or 2000x4000 mm.

Applications

The area of use of this material, due to the simplicity of processing and connection, is very wide. It can be easily drilled, sawn and cut. HDPE and LDPE panels can be bent and take almost any shape. They have found their niche in the food, chemical, automotive and other industries. They make a lot of everything, from food containers to swimming pools. High molecular weight polyethylene, in addition to all the listed places, is also used in the military sphere due to its improved properties - plates for body armor and helmets are made of it.

In the next video, you can take a look at working with polyethylene sheets.

Very easy to understand, thank you.

The comment was sent successfully.