All about Sigma tile cutters

Sigma di Sergio Ambrogiani & C. sas is one of the few leading brands in the world of professional tile finishing equipment. The company is located in Italy and has been known since 1964. Sigma provides a successful solution to the most complex problems with absolutely any type of tile, including porcelain stoneware.

Peculiarities

There is no special secret in the popularity of the Italian tile cutter from the Sigma brand:

- reliability of the tool;

- wide range of products (for professionals and beginners);

- rich functionality;

- relatively budgetary price tag;

- ceramics is now perhaps one of the most common materials for finishing work.

Ceramic tiles are practical, durable, and have an excellent presentation. Its versatility is known: it looks beautiful in any room, goes well with other materials, and is not that expensive. Laying the tiles on their own, as well as having certain skills, each master will agree with the opinion that tile cutters are definitely simple and indispensable in the process of working with ceramics.

Let us immediately point out one of the features that is important to consider when choosing this device. When choosing, you should focus on the quality characteristics of the tile, therefore, first of all, it is worth purchasing it, and only then proceed to the selection of specific tools for processing the existing material.

Initially, you need to pay attention to the manufacturer. In this sense, Sigma products are best suited.

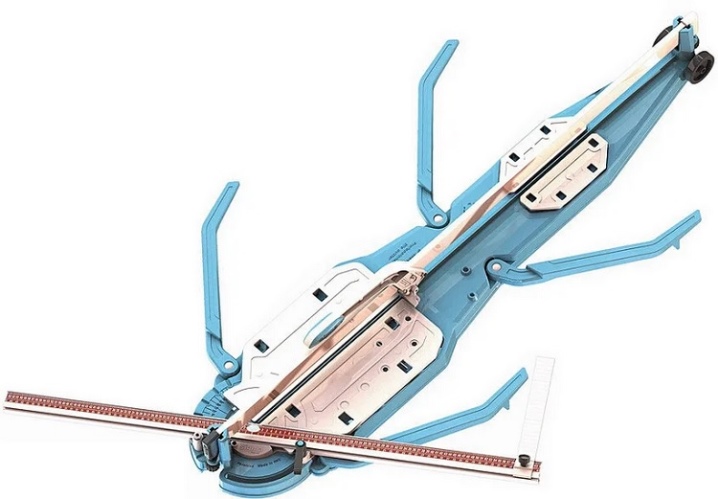

The lineup

Let's highlight a number of the most popular series.

Lines: 3, MAX and Klick Klock

They have common basic parameters, but different handles, which create nuances in individual devices.

- Line 3. Cutting scheme - "for yourself" (roller Ø12 mm, power - 1050 W).

- MAX line. Cutting scheme - "from yourself" (roller Ø19 mm, power - 1200 W). A special rotary system in the handle and an advanced cutter allow you to work very smoothly, as well as to process the thickest and most shaped tile structures.

- Klick Klock series. Cutting scheme - "from yourself" (roller Ø15 mm, power - 1200 W). The transition from cutting the ceramic to separating it takes place by flipping the handle, which then functions as a lever divider for extra hard tiles.

The handles of all mentioned series are interchangeable (replacement time is about 20 seconds). In other words, a pair of MAX fixture and Series 3 handle is the best option for a professional who encounters a wide variety of tile products in their work. This is confirmed by the calculations of the manufacturer's representatives.

TECNICA series

In the models of this professional line, there are schemes for both types of cutting. The self-directed scheme is quite popular in Russia. During the operation, it generates an additional force, which ensures the implementation of cutting of ceramic products of a greater thickness. The scheme "on oneself" is typical for the countries of foreign Europe. The pull motion is sharper for high precision cutting.

Average power (up to 800 W), the use of high-quality elements, thoughtful engineering, the use of high-precision parts, light weight, compactness, budgetary cost for professional models make the products of this series the most suitable option for teams of specialists involved in finishing operations. The line of models from Sigma is quite wide. It presents manual, electric and professional models and modifications with their own characteristics and advantages. Let's consider some of them in more detail.

Tile cutter 2G SERIE 3

This model represents a manual version of the tool. The flat cutter provides a cutting height of 15 mm and a length of 37 cm. The design is equipped with a movable divider, a roller cutter with a variable (6-12 mm) diameter. The device is quite light and compact, it is designed for cutting according to the scheme "from oneself", which allows performing precise manipulations, making cuts sharper and faster. Tiles with a thickness of 15 mm are not a problem for him, since the cutting is carried out with a force of up to 600 kg.

The compact dimensions of the tile cutter allow you to cut to a decent depth, so the device is suitable for even large tiles. In addition, the built-in ruler, placed close to the worker, greatly simplifies the entire cutting procedure. It has two scales and a convenient retainer. The angles of rotation can be varied in the range from -45 to + 45 °. The convenience lies in the fact that when preparing the tool before transporting it, you can easily attach the measuring device to the body of the tile cutter.

Model 3BM (professional version)

This device is very powerful - the cutting force reaches 1150 kg. At the same time, the least force is applied from the side of the cutter, so it is possible to produce high-precision cutting. The device is capable of cutting relief, as well as hard and thick materials. High power and a combination of smoothness and smoothness of cutting is provided by a special divider handle. The cutting length is 60 cm and the diagonal is 42x42 cm.

Cutting scheme - "from oneself". The device has a special button that allows you to quickly fix the ruler at the desired angles. For convenient movement of the ruler, it was fixed on the platform along the rails.

Tile cutter 2D4

Professional hand tool with a cutting length of 610 mm and a thickness of 22 mm. The device belongs to the TECNICA series, designed for cutting tiles up to 22 mm thick. The separating force is about 800 kg, and the cutting pattern is "pushing yourself".

The rotating measuring element is equipped with a double scale and is highly accurate. The 2D4 product is equipped with a 16mm roller and stop for serial operations. The spring-loaded work table creates additional convenience in the operation of the device.

Usage Tips

The process of cutting tiles using manual tile cutters does not require any special skills. But before starting the operation, the device must be checked for possible damage. For example, the cutting head rotates easily and freely. Its surface should have a rounded configuration, free from defects and burrs. The carriage works smoothly. For this purpose, the models use special radial bearings. It is also important to check the bed, the cleanliness of which is the key to a high-quality operation. The product to be cut is marked in accordance with the specified parameters.

The tile should be positioned on the bed so that the markings coincide with the line of movement of the carriage. The distance to the cut from the edge of the board should be about 10 mm, otherwise a neat cut will not work. The carriage must be guided exactly along the markings and with a certain effort, the intensity of which must be felt and controlled. This is important because it is not difficult to push through the tiles, and it is important to cut the glaze.

The roller cutter passes over the surface once, otherwise the cut will not be entirely correct. The handle should be in the working position, then abruptly lower it - the workpiece breaks along the intended cut. Before using the tile cutter, it is recommended to soak the ceramic tile, as this will greatly simplify the cutting. A drop of oil is applied along the cutting line, which makes the movement of the working surface of the device more smooth and light.

There is also a manual tile cutter (Sigma grade 7A), designed for cutting both porcelain stoneware and ceramic tiles, with a separation force of up to 500 kg. The cutting height of this device is 12 mm, and the cutting length is 33 cm. Model with a variable diameter of the roller cutters is 6-12 mm. The incisors contain a titanium base. The device is placed in a convenient case.

Tile cutter users should be aware that 12 mm diameter cutters are used for Pull-on brand devices, which are designed exclusively for cutting products containing a glass base.

The comment was sent successfully.