Choosing dowels for foam blocks

Questions about which it is better to choose dowels for foam blocks sound quite often, because this building material has gained popularity relatively recently. For a long time, it was believed that block buildings and structures should be erected immediately with special embedded products, allowing the necessary hanging elements to be fixed on the surface of the walls. Today this problem is easily solved with metal and plastic dowels - to understand the assortment and find the right parts, advice on their selection and an overview of the products on the market will help.

Peculiarities

It is no coincidence that dowels for foam blocks were used. In direct contact with screws or screws, the connection in walls made of porous, brittle material is weak. The fasteners simply do not stick to their surface. The use of dowels eliminates this drawback, makes it reliable and safe to hang shelves, household appliances, sanitary and hygienic equipment, and decorative items. A similar role in the walls of houses made of foam blocks is played by embedded parts, but it turns out to be quite difficult to think over absolutely all the subtleties of the arrangement of furnishings.

By means of dowels on the vertical surface of a block partition or solid structure you can fix pictures and mirrors, sconces and curtain rods, plumbing and pipes, shelves and pieces of furniture, equipment, household appliances.

Such fasteners are quite reliable, provide high strength of the connection, and prevent crumbling and destruction of the wall material.

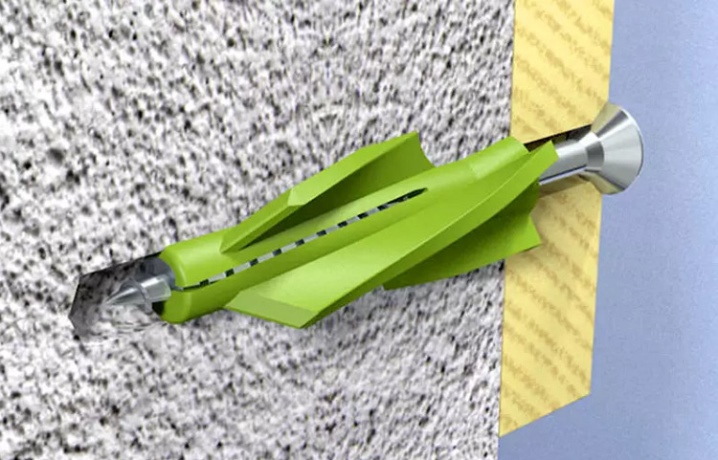

For foam blocks - surfaces with a cellular structure, fasteners with a certain set of characteristics are required... It must have a sufficiently large contact area to guarantee reliable adhesion to the material. At the same time, the fixing parts themselves are multi-component, consist of:

- hollow bushing with spacer;

- rings and half rings;

- screw.

So that the dowels after installation do not scroll in the hole under the action of loads, they are equipped with special teeth. They play the role of a stop in the thickness of the material. According to the field of application, there are options for facade and interior work.

Such products are installed in a specially prepared hole by screwing them in or hammering them in.

Varieties

When selecting suitable dowels for foam blocks the main choice usually has to be made between metal and polymer products. Each of these materials has its own individual characteristics that determine their purpose and field of application.

Metallic

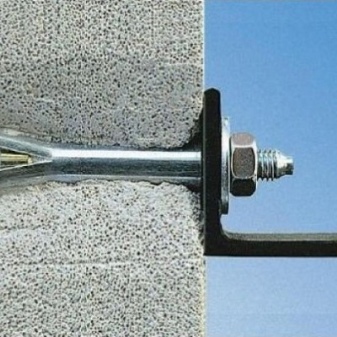

This type of dowel differs high mechanical strength... They are used for fastening and hanging massive products or in areas of linear communications that are of the greatest importance. It is imperative to use metal products in rooms with a high level of fire hazard. With the help of such dowels, facade elements, wall decoration, racks and shelves are attached. Each metal product has external teeth and spacer segments.

M4 screws can also be classified as dowels. This mount is made of metal. In addition to the usual cutting, it has a expanding element, which, after installing the product in the wall, ensures its reliable fixation.

Immediately after tightening the screw, the mount can be loaded without requiring additional manipulation.

Plastic

Polymer materials are widely represented in the manufacture of dowels for foam blocks. The following options are most commonly used here.

- Nylon. Durable elastic material that is not subject to corrosion, destruction by changes in temperature and humidity. Dowels of this type are wear-resistant, suitable for construction and installation work of any complexity. The withstand load is relatively low, it can be varied by changing the diameter of the product.

- Polypropylene / polyethylene... A highly specialized variety. It is used mainly for the installation of plumbing communications. Withstands a fairly intense operating load.

Plastic dowels are most often used indoors, they are not designed for a significant weight of products.

Combined

This category includes dowels also known as chemical anchors... They use a plastic sleeve and a metal screw or hairpin. The kit includes an injection compound, which, when the product is screwed in, forms an additional adhesive layer for fasteners. In terms of their characteristics and bearing capacity, chemical anchors are 4-5 times superior to conventional screw fastening. The adhesive used contains cement mortar and organic resin.

Both metal and plastic dowels can be framed. They are combined with galvanized steel screws, used for the installation of window and door frames, other similar structures, guides.

Which one is better to choose?

The main recommendations for choosing dowels for foam blocks are directly related to the type of accessories and fixtures to be hung on the wall surface.

Some useful tips include the following.

- Mounting a sconce or a mirror, flexible piping of plumbing fixtures, washing machines does not give a significant load. Here you can get by with the use of nylon polymer dowels with a diameter of 4 to 12 mm.

- Through-type fasteners inside or outside the room are required when creating decoration. Special dowel nails are used here.

- In rooms with high fire safety requirements, only metal fasteners are used. It is better to choose metric screws for them.

- When laying rigid pipelines for plumbing, sewer purposes, metal dowels and clamps are used to attach them to the wall. The dimensional parameters of the screw-in fastener must correspond to the level of the loads received.

- When finishing facades from foam blocks, specialized dowels are used. In this case, the mount must have a stainless metal structure with increased weather resistance.

- Heavy furniture, shelving structures, storage systems are fixed on metal dowels with the highest load-bearing capacity... They must sink deeply into the wall and withstand significant loads.

- When installing door and window blocks, guides for sliding elements, special frame dowels made of plastic and metal are used... The type of fasteners directly depends on the intensity of the planned loads.

- To fix the wiring on the surface of the walls made of foam blocks, a special fastening is used - a dowel clamp made of durable nylon. At the same time, the screw is not screwed into the product.

If you need to hang a light paper calendar, a photograph, a compact picture in a frame on a foam block wall, you do not need to screw in a dowel. It is better to use a regular nail.

With minimal load, it will cope with its task just as well.

Mounting

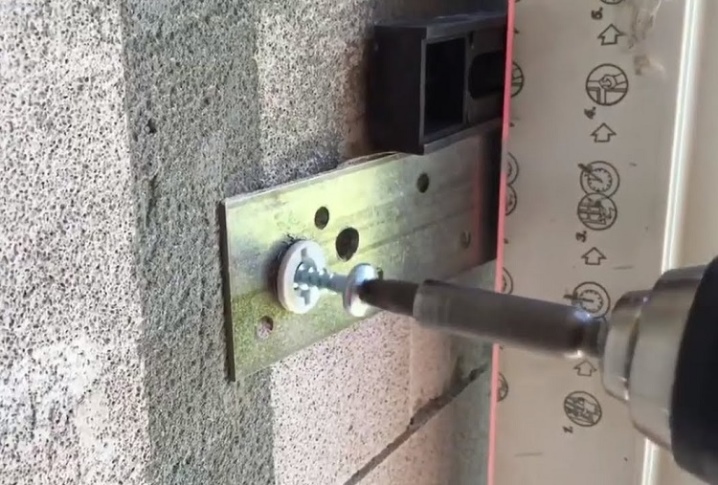

Installation of both plastic and metal dowels in foam block walls follows the same scheme. To carry out the work, a special mounting tool is used in the form of a handle with a tip of the desired shape or a regular hexagon. The procedure will be as follows.

- Drill a hole in the wall. It should be located in the place of installation of the dowel, correspond to the diameter specified by the manufacturer of these elements.

- Remove crumb. The prepared hole must be cleaned of dust and other consequences of drilling. Any interference can affect the correctness of further installation.

- Install the dowel in the place of attachment. This is done using a nozzle.

- For screw-in dowels, you will need to make rotational movements. It is important to take into account the direction indicated by the manufacturer.

- Hammer-in types of fasteners are driven in with a rubber-headed hammer. It will not damage the honeycomb wall. These dowels have large spacing teeth, which, after installation, act as spacers in the drilled hole.

- Chemical dowels are mounted in the same way as conventional ones, but with the installation of a glue capsule. Then the hardware is mounted with a threaded connection.

After installing the dowels, traditional fasteners can be screwed into them. Once inside the cavity, the screw will cause the collet segments to collapse. This will make the fit of the base itself tighter, eliminating accidental loosening or a decrease in the mechanical strength of the fastening.

It is important to remember that foam concrete is a material that is not too resistant to vibrations and shock loads. It cannot be drilled with hammer drills, it can be used for making holes with impact drills. A delicate influence is needed here.

It is better to get by with an ordinary hand or electric drill, using the rotation mode.

You can find out how to fix heavy objects on the gas block from the video below.

The comment was sent successfully.