Bathroom wall decoration with PVC panels

If, when choosing a finishing material for a bathroom, preference is given to PVC panels, then questions arise about their installation. This process is clear to everyone, because the panels can be installed without the involvement of a specialist from outside.

However, you need to know certain nuances.

Peculiarities

PVC panels - a decorative material made of rectangular or square plastic, is a kind of alternative to ceramic tiles. In contrast, they do not need to be docked independently, achieving an identical gap between the elements.

Most of the panels are distinguished by a special connection technology. It is conventionally called suture and seamless. Externally, seams are visible in every finish. The difference is that seamless panels are neater and thinner. Other varieties do not have this attachment.

Their use is associated with preliminary preparation of the base - it has to be cleaned from the old cladding: paint, tiles, plaster. The installation technology can be frame or frameless - it depends on the evenness of the walls, communications, the footage of a particular room. The installation method largely depends on the difference in the height of the walls: if their height and geometry are far from ideal, then you have to mask the flaws due to the frame.

In one case, the panels have to be glued to the base. Frame technology involves the manufacture of lathing (structures from profiles). A void forms between the base and the panels. No glue is needed here: the system is created from a metal profile and special fasteners. Depending on the type of panels, the panels can be fastened vertically or horizontally.

This material is included in the line of materials demanded for cladding. It has an elastic, but not soft structure, does not change it, but is not designed for significant mechanical damage. If you hit it, then dents can be left on the surface. The resulting scratches cannot be masked or painted over - the material does not provide for this.

It does not accumulate static electricity and has antibacterial properties. In addition, the panels are easy to clean - to clean the surface, it is enough to wipe it with a clean damp cloth. High-quality material is not afraid of household chemicals.

Advantages and disadvantages

Plastic panels have many advantages:

- They are aesthetically pleasing. With their help, you can decorate the interior of the bathroom in any stylistic solution.

- The raw materials used are high-tech. It is created on modern equipment, taking into account the requirements of safety standards.

- The range of cladding and color palette is varied.

The buyer has the opportunity to choose panels of any shade.

- The panels differ in texture. Its imitation ability allows you to change the aesthetic perception of the bathroom. The texture easily conveys the material of wood, marble, stone, brick.

- The material is resistant to temperature extremes. It does not change its structure under the influence of moisture and steam, it is resistant to light.

- The panels can be attached to different floors. They look beautiful on walls and ceilings.

- PVC trim can become an independent background of the bathroom or its stylish accent. She can zone the space of the room.

- The panels hide communication systems well. They can be used to decorate the bath screen and the space under the sink.

- It is not difficult to assemble a frame for installing such a system.It is he who is the guarantor of the durability of the finish.

- These panels look great with other bathroom finishes: they can be combined with ceramic or mosaic tiles.

It is worth noting a few disadvantages of this finish.

- When preparing the base, it must be treated with an antistatic compound. Sometimes, during operation, molds form in the cavity between the material and the surface.

- The cost of the panels cannot be called budgetary; the savings are obtained due to the acceptable price of work.

- The glue method cannot be called good if the walls differ in curvature and convexity in height.

- The frame system "steals" centimeters of the usable area of the bathroom. This is not scary for a spacious bathroom or toilet, but not always good for a small room.

Panel types

Conventionally, all existing types of plastic panels can be divided into 2 types:

- wall;

- ceiling.

The difference between them lies in the thickness - the versions for the ceiling are thinner. This is due to a decrease in the weight load, which is especially important for loose floors of a panel house or a private building made of wood and foam blocks. The material differs in width and length, some varieties are more reminiscent of sheet material.

The parameters can be small - 100x50 cm. Other decorative panels are similar to slats - they are mostly thin, but strength is an important criterion for buying: the larger it is, the more durable the sheathing.

By the type of texture, the varieties differ in reflectivity: lamellas can be matte or glossy. The use of gloss on the ceiling allows you to visually stretch the length of the bathroom walls, make the space larger. Matte options are especially harmonious where imitation of other material is needed.

Plastic goes well with mirror inserts - such panels are used to decorate the ceiling.

Interesting texture with relief. With its help, you can add a special flavor to the bathroom interior. Typically, these varieties are made for finishing wall floors. Sometimes they are more like sheet materials. They can be thin or moderately dense, but their strength allows them to finish walls near high-use areas.

Preparation

It is not difficult to mount panels in the bathroom, but you will need to prepare the base, stock up on facing material, frame components in the case of this technology, as well as inventory.

For the wireframe method, the following may come in handy:

- guide rails (lathing profiles);

- finishing plastic profiles;

- plastic corners;

- screwdriver;

- hacksaw;

- self-tapping screws;

- dowels;

- ruler, pencil;

- building level;

- clamps;

- crosshead screwdriver;

- construction stapler;

- puncher.

Depending on the type of panels, you will have to buy a ceiling or floor plinth. Sometimes the auxiliary material can be polyurethane foam, sealant and insulating material. When using the glue method, buy glue liquid nails. Molding can be connecting, ceiling, end, internal, universal, external and starting. The choice of the desired variety is made based on the perspective of the walls or ceiling, it depends on the presence of protrusions, niches, and sloping walls.

Preparation of the base usually does not take much time. It is necessary to strengthen the base, which is especially important for porous, loose floors. They usually crumble, as they were made in violation of construction technology. It is impossible to make a high-quality lathing or a classic base for glue on them.

Begin by leveling the surface. If there are bumps on it, then they are removed. At this stage, the surface is primed with a primer with a high penetrating ability - it makes the structure of the floor homogeneous, binds dust and cracks. The primer is applied in an even layer. When dry, it forms a crystal lattice that increases adhesion.

Visible defects - cracks, chips, potholes - are trimmed with cement-based plaster and putty. Rotband-type gypsum-based mixtures cannot be used in the bathroom, as they damp and peel off from the base. If it is necessary to make the corners straight, then this process is carried out by means of a perforator. Then it is the turn of the primer.

A second layer will link all the previous ones.

Calculations

When the base is prepared, proceed to the construction of the lathing. However, its manufacture directly depends on the calculations made. These include accounting for the number of fasteners, profiles and guides. The calculation allows you to determine the amount of material required.

To find out how much profile you need, you have to take into account several factors:

- the position of the components of the crate is strictly perpendicular to the panels;

- the optimal gap between the panels should be 3-5 cm;

- additional slats are used for the door opening;

- installation is carried out around the perimeter or partially;

- in addition to the crate, you need guides;

- the calculation data are rounded up.

The number of fasteners depends on the length of the panel to be installed: usually 1 fastener is used for every 50 cm. When working with clamps, they will take 20 pcs. for 1 sq. m. The number of facing panels depends on the volume of the trimmed surface.

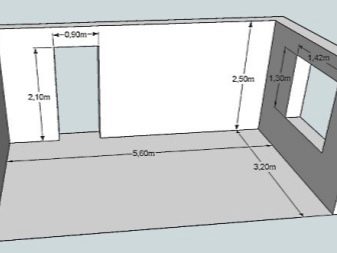

In the event that it is necessary to sheathe the entire wall with panels, proceed from its height. Then the total length is divided by the width of 1 lamella. The calculation of the panels near the doorway is performed separately. The plinths (plinth) are counted along the perimeter, measuring the distance with a tape measure. If sheet material is used in the work, then the calculation of PVC plates is determined by the area formula.

Installation

You can sheathe the surfaces of the bathroom floors with PVC panels with your own hands, following simple instructions. It should be noted step by step the main nuances of installing the frame method on a metal crate. It is undesirable to use wooden options - it will not give perfect joints.

Determine the area of the surface planned for processing. The area of the door and window opening, if any, is removed from it.

You can use the formula Stot = L * H - (S1 + S2), where:

- L - length;

- H - width;

- S1 - area of the window opening;

- S2 is the area of the door opening.

At the same time, they make a small margin for pruning. For fastening, you can use staples and a construction stapler. It is not difficult to fix the panels to the wall with their help. The glue method is a quick installation method, but if you need to replace the lamella, then this will be problematic.

Before creating the lathing, check the evenness of the surface again using the rule.

- On the frame. For the frame method, horizontal guides are initially installed along the perimeter. To do this correctly, start with the markings for attaching metal profiles. When ready, drill holes in the marked places.

Then the guides are attached using self-tapping screws.

Install horizontal slats depending on the desired strength. For example, when lining the ceiling, it is recommended to fasten at a distance of 30-40 cm. If it is a wall frame, then the distance can be 40-50 cm. The end sections of the profiles should ideally fit into the corners of the room. After the frame mesh is ready, you can start attaching the panels.

They start cladding a bathroom or toilet from the very corner of the door - this technique allows you to get rid of defects in cladding. Keep the joint sealant ready.

To make the corners look beautiful and professional, use a kind of corner (external or internal profile in the form of the letter L). The plinth is used when joining the floor. When the corner profile is installed, a PVC lamella is inserted into it. Then it is fixed to the frame rail.

Further work is to insert each subsequent panel into the gap of the previous one. This must be done carefully, pressing firmly without much effort, so as not to damage the plastic.If, when facing, you need to make a hole for the outlet, then it is done before being attached to the wall. To give the finish a complete look and hide flaws, ceiling and floor skirting boards can be glued on top and bottom.

- On the glue. This method is simpler and more accessible to every man in the street, since there is no need to use metal fasteners and profiles. The principle of operation does not differ from frame installation: installation starts from the corner. The panels are trimmed to the desired size, after which one such panel is taken and liquid nails are applied to the back side. You need to use glue under the construction gun. The composition is applied pointwise - in a checkerboard pattern.

One cartridge is usually not enough - the average consumption is 1 piece. 5 sq. m. The glue should be applied away from the edge. It will not be possible to remove its excess from the front surface - this will ruin the panel and the appearance of the finish. After application, the composition sets quickly. You need to take the panel and put it in place, pressing it with your palm.

However, angles are rarely perfect. To glue the first lamella correctly, you will have to use the building level. Often, craftsmen, in order to prevent sliding of the panel, fix it from below and from above by means of self-tapping screws. If you fix it in this way, then it will not budge. Apparently there will be no fasteners - they are covered with baseboards.

Start strips and corner fittings are used as needed.

Sometimes (for example, in a toilet) a baseboard is sufficient.

Useful Tips

The advice of professional craftsmen will help to simplify the selection and installation of PVC panels.

- When buying material, you need to squeeze the panel with your fingers at the end. If it is soft, it will dent. You cannot take such material.

- If the cladding has a pattern, then it is necessary to check its coincidence with each panel. The lines of the pattern should go from one panel to another.

- The durability of the print is important. On low-quality material, the pattern is erased by friction - such raw materials for finishing are not suitable.

- High-quality cladding has no gaps when joining. It is necessary to connect the panels and inspect them for cracks. Their presence speaks of a marriage and a low-grade product.

- The thickness of all elements must be identical, otherwise the difference in the plane will be noticeable against the background of the built-in backlight.

- The plasticity of PVC panels matters. Low-grade goods crack at the slightest bending - this is an obvious defect, a PVC recycled product with low cost and poor quality.

- In order not to be mistaken in the calculations of fasteners, experts recommend buying clamps and self-tapping screws in packs, based on the width of the panels used.

- The installation of vertical panels increases the height of the ceiling and promotes better moisture removal. When laying horizontally, water will linger on the lamellas.

You can cut the panels lengthwise and crosswise using a cutting knife with a sharp blade. Sometimes a grinder or a hacksaw for metal is used for this. However, the latter method is not in demand due to the laboriousness of the work. In this case, a file is used with a minimum tooth.

- The stripes can crush the room. In order to prevent this effect, it is preferable to install panels in light shades in a small bathroom.

- For a spectacular design, you can combine panels of different textures and sizes - this will make the interior boring.

- It is better to choose the color of the finish according to the general concept of stylistics. The tone should not match the background of the floor or furniture. The priority is soft and muted paints.

- The markup is carried out based on the location of the communication systems. It is not always possible to disguise them. If possible, use a dummy panel.

- Plinth for wall cladding allows to strengthen the lower fastening of the panels.

- Panels with a smaller seam thickness look better.

In the bathroom, additional crushing is undesirable - in addition to not aesthetics, it is associated with the complexity of cleaning.

Beautiful examples

You can evaluate the possibilities of facing the surfaces of the walls and ceiling of the bathroom by paying attention to the examples of the photo gallery. This will allow you to see different ways of decorating, as well as combination techniques.

- This example uses wall panels with an accent in the bath area in combination with floor tiles. Successful installation of fixtures.

- Here, wood-like panels are used as a background design. A frame structure for finishing the bath screen has been made.

- The original technique of suture technology. Here, narrow slats are used for one of the bathroom walls.

- Accentuation of the shower area and decorative panels that protect walls in particularly hazardous wet places. The skirting board completes the decoration.

- Panels with three-dimensional effect create a special atmosphere in the bathroom interior. Accentuating the wall and partitions contributes to a clear organization of the space.

- Stylish choice for bathroom ceilings. The lamellas look impressive against the background of brick-like wall decoration and marble-like flooring material.

- A brutal solution in the loft style. Combination of panels with brick finish. The white color of the lamellas softens the rough texture of the brick.

- Accentuating the wall with the location of the sink and mirror. Used textures for bleached wood.

An overview of wall panels is waiting for you in the next video.

The comment was sent successfully.