Choosing accessories for PVC panels

Plastic panels have a number of important performance properties, in addition, they are considered an environmentally friendly, harmless material, therefore they are often used for interior cladding of premises. To install the material, you need components - fittings, appropriate fasteners, selected based on different coating parameters.

Purpose of fittings for plastic panels

Wall and ceiling panels made of PVC are a functional and durable coating, it is presented in a large palette of colors, has a different texture and is ideal for decorative finishing of residential premises. Sheets are made from a polymer mixture using special equipment - a plasticizing machine or an extruder. The cut lamellas are painted with organic dyes, and the top of the canvases are covered with an antistatic agent and a protective varnish - that is why the material looks good and has high performance.

However, it is not enough to choose a perfect plastic coating for installation - you will need to purchase fittings and fasteners, which are currently not just a set of separate parts, but also a multifunctional and technological mechanism that performs different tasks.

Purpose of components for PVC assembly:

- fixing panels to ceilings, walls and flooring;

- connection of trim segments with different thicknesses;

- design and connection of joints at different angles;

- formation of structures of any scale and shape.

The main material for the production of fittings is high quality steel, although some parts can be made of alloys based on magnesium, titanium, aluminum, processed by pressure. Polymer elements are used more for decorative framing than for creating a durable sheathing.

A characteristic feature of the profiles used is ease of use - they can be easily adjusted to the required dimensions by cutting with an ordinary construction knife. In some cases, it is better to fix the outer molding with adhesives, thanks to which the panels are not subject to damage and deformation.

Types of components for finishing PVC canvases

Auxiliary parts for mounting plastic fragments are manufactured in accordance with GOST 19111-2001 standards, which speaks of their quality and safety.

For assembly, different types of molding are used.

- U-shaped profile, starting or initial - the strip from which the laying of ceiling panels begins, it is used to cover the transverse edges of the panels. If the product is used for walls, then window slopes and doorways are decorated with it.

- The end profile in cross-section resembles the letter F, and its central crossbar is pushed forward compared to the top. The part is intended for decorative framing of plastic joints, corner joints, door and window openings.

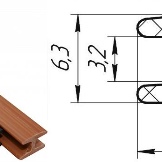

- The H-shaped connecting strip is designed to connect the short sides of the panels and extend their length when there is not enough of it.

- External and internal corner - details that are necessary to connect and design external and internal right angles.

- Universal corner - due to the ability to bend at any angle, it is used to close any corners and at the same time performs the task of decoration.

- The general construction angle (decorative) is required for sealing external plastic joints at an angle of 90 degrees.

- Ceiling plinth (fillet) serves to smooth the transition from the walls to the ceiling surface, covers the joints of the panels.

- For the ceiling cornice, external and internal corners are also necessary, as well as connecting parts with its insufficient length in rooms with a large area.

- Guide rails made of plastic and galvanized steel are intended for the construction of the battens, they facilitate and speed up the assembly of PVC panels.

Components are selected taking into account the thickness of the polyvinyl chloride, a certain color of the finishing cloths. And you should also pay attention to the strength of plastic fasteners, on which the reliability of the structure depends.

Fixing elements for plastic

The method of installing PVC panels, that is, attaching them to the walls and ceiling, depends on the characteristics of the room - the level of humidity, the curvature of the working surfaces, the availability of communications and temperature bridges. In each case, certain fasteners are used, which will be discussed.

There are three ways of fixing.

- The most inexpensive and simplest means of fastening plastic is silicone glue or "liquid nails". You need to choose a special heat-resistant type of product. Silicone dries quickly, has high strength, allows the panels to be assembled in a short time, however, it can be used with a perfectly flat wall surface, moreover, during repairs, this method does not allow replacing damaged PVC lamellas.

- When erecting a frame for cladding with plastic, fasteners such as dowels or nails are most often required - here it all depends on the material of the walls and ceiling. PVC panels have special tongues on their surface, located under the grooves, and fixation is made in them. Based on the fact that the lathing is usually made of wooden blocks, they are fixed with dowels with polymer sleeves. In this case, you can additionally use "liquid nails". This method has its drawbacks - the construction of a frame made of wood is associated with sawing a bar and covering it with antiseptic agents, and this takes a lot of time.

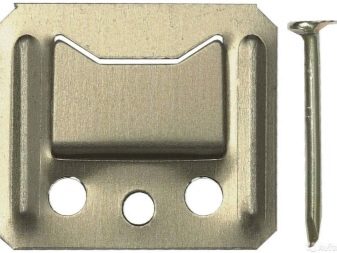

- Kleimers occupy a special place in the installation. They are different in size, but, as a rule, not more than 50 mm. These are special mounting plates in the form of curly brackets made of galvanized iron, have a fastening tongue and holes for nails and dowels. Usually these parts are included in the batten kit. The mounting clip snaps into the groove of the strip in one motion, so that when using it, you can even do without self-tapping screws and nails, since such a fastening is absolutely reliable.

Cleamers are versatile parts, unlike nails, they do not damage the joints and panel locks, they adhere tightly to the surface and provide high quality assembly. Despite the strength of the fastening with brackets, minimal distortions remain, making it possible for the walls to collapse with the integrity of the panels.

Of course, against the background of other mounts, mounting clips are more preferable, the main thing is, when choosing, pay attention to the presence of a high-quality connection of spikes and grooves on the parts.

The use of components during installation

To install PVC lamellas, you will need a jigsaw, a flat screwdriver, a level, a metal saw, a tape measure, a screwdriver, clamps, self-tapping screws ("bugs").

Work algorithm:

- first, a crate is made - it can be made of metal profiles or a bar with a section of 2x2 cm;

- the guide strips are fixed to the base of the walls or ceiling by means of nails made of galvanized steel or self-tapping screws, an indent from their edge must be left;

- if there are irregularities, then the structure should be leveled with wooden lining;

- the starting profile is fixed in the left corner, from which the assembly begins;

- a panel is started on it from the bottom corner and fixed with self-tapping screws so as not to damage the plastic, the fasteners cannot be tightened too much;

- the next sheet is tightly inserted next, it is desirable that there are no gaps between them.

In order for the plates to fit organically to each other, it is necessary to correctly connect them - the panel is inserted into the corner with a thorn, so that the groove remains open for the next sheet. If there is a gap near the thorn, it is carefully trimmed.

Then you should fix the lamella on the crate and now you need a kleimer - its hooks are inserted into the groove, then the element is pressed tightly. The fasteners are fixed with special screws. For plastic use staples up to 2 mm high. Four of these parts are enough for 2 meters in length, however, with a large perimeter, their number can be increased. When working with a screwdriver, it happens that the "bug" turns the mounting clip, but it can be pressed and held with a screwdriver.

When installing PVC, it is important to focus on some points.

- Since the assembly begins with the installation of the box, it is necessary to correctly install the rails. Especially carefully, using a level, the position of the panel installed first is checked.

- In the course of work, you need to monitor the accuracy of the fit of individual sheets of material. There should not be large gaps between them. That is why the plates must be compacted as much as possible.

Ceiling and F skirting boards should always be installed last. While the moldings are intended for decoration, they additionally reinforce the edges of the existing structure.

For plastic panels, you should choose high-tech fittings, and, of course, do not proceed from its appearance or cheapness. With such a task as the construction of a reliable crate, savings are inappropriate. In addition, you always need to focus on the compliance of products with quality standards and GOST.

Video instructions for the installation of PVC panels are presented below.

The comment was sent successfully.