All about veneered MDF

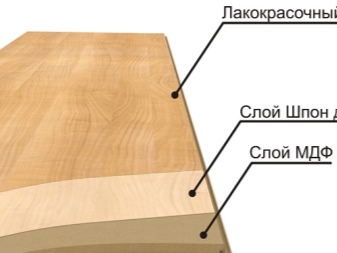

Today, various materials are used for the production of furniture. MDF boards, which are offered in a wide range, are in great demand. This is a medium-density fiberboard that is excellent for the manufacture of furniture facades, decor and has a number of positive characteristics. During the production of MDF boards, modern technology is used - veneering, intended for finishing furniture items.

Peculiarities

Wood with a thin cut is called veneer. To obtain veneered material for further production, modern equipment is used, with which the raw material is sawn or peeled. Elite wood species are often chosen for this. The appearance of MDF is no different from ordinary boards. The main advantage of this material is its cost, which is much more affordable than the prices for natural solid wood. The veneer is covered with a special varnish, which creates protection against mechanical damage and moisture. Furniture made of such material will look stylish and noble, fitting into any interior.

It is worth noting that geometric patterns are often applied to veneered MDF panels in order to diversify the range of materials. In case of damage, paintwork is often used and the defect can be quickly removed.

A distinctive feature of veneer from other types of finishing materials is its high level of environmental friendliness. Even when exposed to high temperatures, the wood produces non-toxic and completely harmless lignin, which confirms the naturalness of the material.

Noting the advantages of veneer, it is important to highlight the ease of caring for such products, since it is enough to use a napkin to remove dirt and dust. Low weight allows you to independently assemble furniture products from MDF boards. In addition, much less raw materials are consumed in the manufacture, and this has a positive effect on the preservation of forests. The application of veneer allows you to obtain a beautiful textured material from which stylish furniture is created. A facade covered with paint and varnish will last much longer, while maintaining a presentable appearance.

Species overview

For the manufacture of veneered MDF panels, different types of wood are used. Walnut, oak, ash, beech and pine are in great demand in the production of the material. As for the varieties, they are distinguished by the way they are processed.

- Natural veneer created by finishing thin sheets without refining. Therefore, such panels look as natural and embossed as possible. The naturalness of the massif is preserved, which is highly appreciated by designers.

- Fine-line technique exclusively soft rocks are used, which are distinguished by a loose structure. The cuts are made quite thin, and in order to give the desired shade, experts use dyes. After that, the plates are stacked, then pressed with the addition of binders. A pattern can be applied on top that will simulate a timber.

- Veneered or colored veneer painted, stained or patinated, so the range of material is quite extensive, you can also choose any shade to harmoniously combine with the overall interior. Such furniture fronts are lightweight and look aesthetically pleasing.

- Multi-veneer is created by reconstructing a natural veneer sheet, during which the pattern, texture and color change. Therefore, as a result, geometric shapes are obtained, and the furniture will look original.

Dimensions (edit)

MDF panels are offered in different parameters, which are always indicated in the description of the technical characteristics. One-sided veneer can be made from 0.6 to 16 mm thick. The standard length of the slabs is 2800 mm. As for the double-sided veneer, the thickness reaches 22 mm, however, panels of 6 mm, 16 mm and 10 mm can be found, it all depends on personal requirements and the scope of the panels.

Colors

The colors of the slabs are offered in a wide range, so everyone can find what meets the design needs. You can choose transparent and translucent slabs, on which a lace pattern is applied. These slabs imitate glass and stained glass; this unusual decor is often used as a separate component that complements the overall interior. The dense monochrome coating of veneered MDF boards is presented in pastel and bright colors. If you need a light facade, you can safely choose panels with this design. The range of solutions can reach 200 options, while the execution can be both smooth and textured.

It should be noted that slabs in white are presented in several shades, which allows you to achieve the perfect design solution and interior decoration... Of course, slabs for solid wood, metal or natural stone are in great demand. This effect is created using films, patination, brushing and embossing.

The texture can be different, thanks to modern technologies, you can get an imitation of any materials, which is a big plus.

Popular manufacturers

There are many factories on the market that offer their products on a variety of terms. This allows consumers to choose not only the desired version of veneered material, but also to study the price range, technical characteristics and find something that meets all the requirements and high standards.

- Russian company "EuroShpon" offers MDF boards in a wide range, which is a worthy analogue of valuable wood. The material is produced in Holland and delivered to the territory of the Russian Federation in a rich variety of sizes, shades and textures.

- "Veneer Factory" has been working in this field for many years, so it can offer decent product options to its customers. The assortment includes natural veneer, fine-line and even designer.

- Orchid is a popular manufacturer of veneered MDF., in the catalog of which you can find a wide variety of materials for facades, furniture manufacturing and decoration. In the course of production, species such as oak, beech, ash and even mahogany are used. If you are interested in exotic options, for example, birch, wenge, walnut, maple, the catalog contains a complete description of the material.

- Venezia veneer factory has already earned the recognition of its customers, among which there are many furniture companies. The production of veneered panels is organized at the highest level, in the assortment you can find everything that the buyer may wish for.

Where is it applied?

The most demanded area of application of veneered MDF is the production of furniture facades. Finishing kitchen sets with this material is in great demand, but it all depends on what kind of wood was taken as a basis. For example, walnut, which has a light and pleasant grayish tint, is ideal for the manufacture of doors. As for pine MDF boards, they are often used in the production of expensive and exclusive furniture.

Oak is distinguished by its durability, so this kind of veneer material is often used for finishing door structures. A maple product is ideal for interior decoration in light colors.Products made from MDF boards will serve for a long time, maintaining a presentable appearance, if you take care of the surface and initially choose a manufacturer that guarantees quality. Veneered facades attract a lot of attention not only due to their excellent characteristics, but also aesthetics, the choice of texture and textured patterns, and other advantages.

A kitchen made of such material will be an excellent solution that will ennoble the interior and refresh the atmosphere.

In the next video, you will see the installation of veneered MDF panels on the wall.

The comment was sent successfully.