All about moisture-resistant solid tongue-and-groove slabs

When renovating and constructing new buildings, you always want to do everything well, so as not to redo it later. To do this, you need to use modern and high-quality materials. One of these - monolithic tongue-and-groove plates, the use of which gives a more significant economic effect than brick or concrete already familiar to everyone. This saves time and resources. Now it's safe to say that traditional building materials will soon be a thing of the past.

Characteristic

Tongue-and-groove plates (PGP), or blocks, Is a large format building material for the construction of walls and partitions. Outwardly, they resemble a rectangular parallelepiped, on the side faces of which there are grooves and ridges (spike-shaped projections). Because of these features, they got their name.

For the production of these products, stucco with impurities or a solution based on sand and quicklime (silicate) is used.

That is, there are gypsum and silicate monolithic blocks. Let's consider their parameters.

- The weight... The panels are divided into two types according to their design - monolithic (solid) and hollow. A solid tongue-and-groove slab differs from its hollow "sister" in weight and strength. Walls built from solid slabs will be stronger, but significantly heavier, the difference in weight is about 25%.

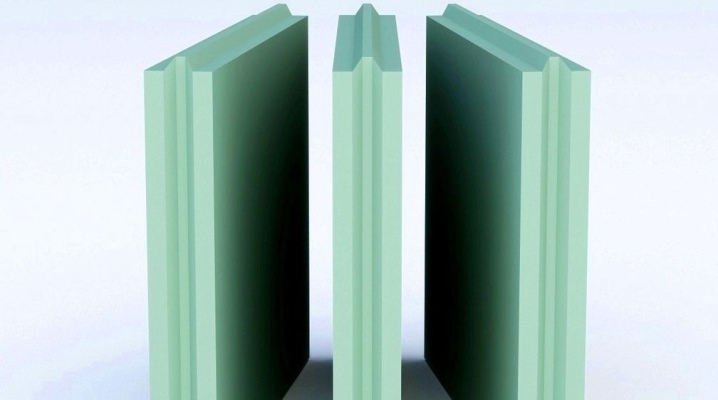

- Moisture resistance... The blocks are available in two versions - standard and water-repellent. For gypsum blocks to become water resistant, special additives and treatments are required. Typically, for this purpose, Portland cement and blast furnace slag granules are added to gypsum. To easily distinguish moisture-resistant gypsum blocks from ordinary ones, the first ones are painted green. Silicate initially are not affected by moisture.

- Fire safety. Panels made of gypsum are capable of resisting an open fire (temperature about +1100 C) for at least three hours without losing their bearing capacity. Silicate blocks fight fire just as well; in case of fire, they do not emit harmful gases.

- Gas permeability. Monolithic slabs allow air to pass through well or, as the people say, “breathe”.

- Thermal insulation... This parameter is at a fairly high level. One row of blocks 80 cm thick can replace a four-meter brick wall.

- Height... For gypsum tongue-and-groove blocks, it is a maximum of 4.2 m for walls. For lintels - 3.6 m. There are no restrictions for silicate panels.

- Soundproofing... The noise factor for this type of product ranges from 35 to 42 dB. And what is characteristic, for hollow products, this parameter will not be good, and to enhance noise suppression, you will have to additionally sheathe the wall with plasterboard. Monolithic blocks will do this better.

The main advantage of tongue-and-groove panels is the speed and simplicity of their installation. Even a person who has never installed them can easily cope with this work.

Also, the advantages of full-bodied blocks include:

- the ability to use in regions with any climate;

- environmental friendliness;

- do not conduct electric current through themselves;

- not subject to decay;

- do not have any smell.

But there is also a minus - it is price... At the moment, such products are quite expensive. But there are more advantages, and this will more than pay off all the costs.

Dimensions (edit)

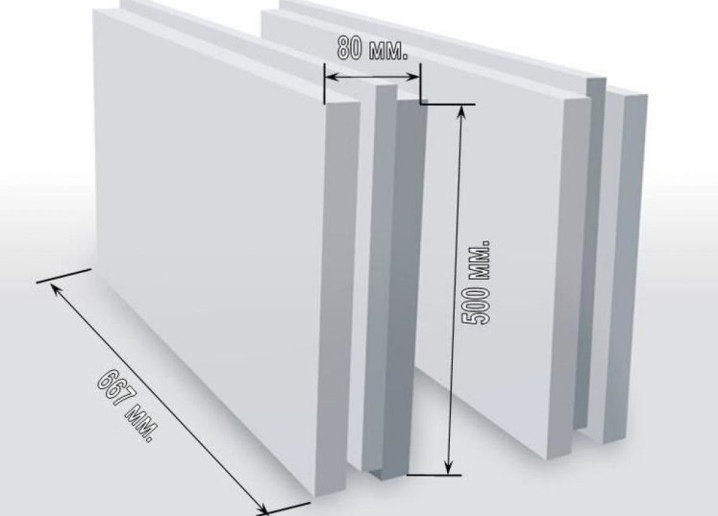

The most common dimensions for gypsum monolithic slabs with spikes - 667x500x80 mm, 667x500x100 mm. In accordance with the current GOSTs and TUs, it is also possible to produce blocks of 900 × 300 mm; 800 × 400 mm; 600 × 300 mm.

Thickness products can be 80; 100 and 120 mm. For silicate blocks, the dimensions are somewhat smaller, the length and width are 500x250, and the thickness can vary - 70, 88 and 115 mm.

How is it used?

Due to their remarkable properties, tongue-and-groove blocks made of various materials have practically been ousted from installation of lintels in buildings heavy brick or rather unreliable drywall. But they are used not only for these purposes. They are widely used for insulating building facades, increasing sound insulation and masonry of load-bearing walls.

But The main area of application of waterproof solid tongue-and-groove slabs is still rooms with a humidity of more than 60%, that is, bathrooms. Neatly executed panel surfaces allow to exclude wall plastering and immediately start laying tiles. Solid blocks are able to withstand decent loads, you can hang furniture on them.

If you need to erect load-bearing walls, then it is worth examining the parameters of the products. The best choice would be panels with a thickness of 100 mm and 120.

In the case when the panels are used as facing, you should use moisture resistant or silicate.

Another point that few people remember is that moisture-resistant solid slabs can apply for the construction of premises, in which heating is not provided. They do not react to temperature changes, and there will be no condensation inside.

There are quite a lot of manufacturers of these products on the market now, but you should trust the time-tested ones.

How to make installation of walls and partitions from tongue-and-groove plates, see below.

The comment was sent successfully.