What are pins and how to install them?

Nagels have found application in a wide variety of installation and repair work: they are used in construction, including in housing construction, and with their help they install decorative items for the interior. Below you will find more information about the purpose and correct use of this connection.

What is it and why are they needed?

This type of fastener is widely used. This happened after its very valuable properties were discovered, which turned out to be extremely useful in construction.

Nagel is a type of pin fastening that protects against the negative consequences of deforming loads on building structures and resists many dangerous factors that must be considered: bending pressure, displacement. Such fasteners are used as a connection in structures made of a wide variety of materials, be it beams or concrete blocks, from which the walls of buildings are erected.

The nail mount is a kind of nail, and it can be in the form of a metal self-tapping screw, or it can be a wooden rod that has absolutely no thread, a head and a sharpened tip.

Due to the fact that there are several varieties, the characteristics of these types of compounds may also differ. Certain materials of the pins correspond to properties characteristic only of them, which must be taken into account in any type of work. When the construction of block houses is carried out, you can find wooden pins, which are often used here, as they effectively cope with the connection of parts.

If it becomes necessary to install concrete, then the same pins come to the rescue. They become extremely popular when other fastenings are impossible - for example, when the most ordinary screw is screwed in, and the concrete is too hard for this.

What is the difference from the dowel?

Different types of fasteners have different requirements. Thus, the same type of fastener is not suitable for every design. Among others, fastenings are performed with dowels. Let's consider what it is and how they differ from the nail connections.

Dowels are also used in the assembly of various structures: furniture, log structures. The pins can be longer and do not have pointed ends. Despite the fact that there is some difference in the structure and size of the dowels and dowels, they are equally successful in connecting the required parts.

When dowels are used, the strongest contact of the pin with the material is created, it follows that no movements of the fastening element are assumed in the structure: the diameter of the hole for it is equal to or less than the diameter of the pin. When mounting using pins, holes are made that are wider than the diameter of the nail.

Varieties

If you correctly give preference to any kind of dowel joints, then the result of the construction will delight you with strong fastening of ceilings and partitions.

For work on bricks, concrete, metal types of dowels are used, because only such a device is capable of holding various objects firmly in weight under significant loads. It might seem that the nail looks like an ordinary screw and has no structural differences. This is not the case, in addition, the special pins do a better job of fixing.

The pins have a special variable thread.The pitch between the serifs is not the same - its unevenness along the entire screw-in length of the self-tapping screw is provided specifically for better grip.

Self-tapping screws for concrete differ in the type of coating.

- Brass. They differ from others in gold-colored coating and in the scope of use when installing small light structures, indoors. Thanks to their beautiful color, they can be safely used in decorative structures. However, they are easily deformed and corroded.

- With oxide. They are black. Scope of application: indoors or in places where water does not get into. Black self-tapping screws are susceptible to rusting.

- Silver with zinc. The most practical, as they can be used in places with any humidity, outdoors and indoors.

A hole in concrete is not always preliminarily made under the dowel. When working with porous materials, it is important to ensure high-quality contact between the self-tapping screw and the base. This rule applies to aerated concrete, as well as foam blocks.

The dowel prevents the beam from shifting horizontally and at the same time does not interfere with the vertical shrinkage of the house - thus, it will not hang and gaps will not form. Pay attention to the type of wood. It should at least correspond to the breed of crowns, or be slightly more durable. Birch and oak pins are made, and larch pins are often found.

It is noted that in practice, wood joints have a positive value, because wood can expand and dry out.

The pin must be able to change along with the log - this is how a reliable fastening is carried out. Fixation is performed with hewn pins of various shapes: the cross-section can be in the form of a star, a square. The most popular are cylindrical mounts.

The type of fastening depends on the conditions in which it will serve. It is necessary to assess the damage from external factors such as moisture and stress. For a durable service of buildings, you need to select the types, sizes, coating of dowels, based on their purpose.

By appointment

Any house or bathhouse has at least one window and doorway. They also need to be further strengthened, since there is a risk that the ends of the bars will begin to shift in different directions. Nagels exclude the possibility that the crowns will suddenly lead during shrinkage.

Installation and installation of devices, electrical equipment in the room is not complete without the use of dowels. When you need to hang objects on the wall, special self-tapping screws come in handy in the work, which will reliably fix even the most bulky thing.

To hang a chandelier on the ceiling or install a swing, pins with a hook are used. Not only in woodwork, but also in the connection of various parts with concrete, pins come to the rescue.

The advantage of dowels is that they are useful at any construction site due to their wide range.

For fixing PVC windows, you can take an iron screw on concrete, with their use there is no longer a threat of loosening the windows. Plastic windows are characterized by high sound and heat insulation, but in order for these properties to manifest themselves, it is important to correctly install using pins.

Bolts, nuts and the simplest nails are common fasteners, however, it should be remembered that such clamps do not work in bending, with them the wood can deteriorate, and over time the fastener will become ineffective.

Fixation of objects on the walls, operation during the erection of the roof of houses and in other construction work, strengthening of structures - far from a complete list of things in which nail connections are irreplaceable.

By form

The area of use is also determined by the shape of the thread of self-tapping screws, pins and heads. The cross-sectional shape of the fasteners is round. Cylindrical steel rods and strings are produced. The pins are also made of metal hollow inside - they look like pipes.

Wooden pins are made with a round section.

Square and rectangular are also widespread.Used hexagonal and even with a star in cross section.

Screws for concrete are distinguished by the type of flat heads, which are:

- rectangular - head-hook, loop-shaped;

- hexagonal - they are characterized by the presence of an internal thread, a slot;

- secret - the slot for such screws is cruciform, there are countersink notches that strengthen the fastening in the structure of the walls;

- threaded studs;

- Heads with a hexagonal Torx-slot - such screws are used for fastening with an "asterisk".

The main feature of concrete dowels is a special thread.

- Medium type multifunctional thread. It is not necessary to use a dowel.

- "Fir-tree". The hardware is twisted after the dowel has already been installed in the drilled hole.

- Variable. There are notches on the self-tapping screws. Before installing the dowel with this type of thread, a hole is made with a depth greater than the length of the self-tapping screw. The dowel is not used during installation.

Materials (edit)

You can understand which pins to choose for the construction of a log house, renovation of the interior or other types of installation work if you know about the characteristics of the materials from which the fasteners are made. A well-chosen element will increase the service life of the structures.

Today, the materials for the manufacture of pins are as follows: metal, wood, plastic. Each of them is used as intended by builders.

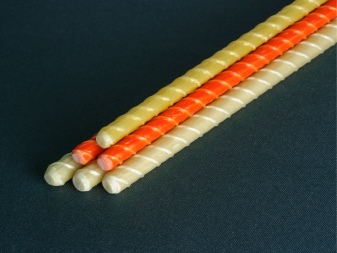

Plastic and fiberglass, as well as the metal look, are commercially available in hardware stores along with traditional wooden dowels. Let's figure out which ones are better.

Metal

In practice, the steel type of fastening can be used in temporary and permanent structures together with wooden pins when assembling wooden houses, as well as in working on concrete, installing fences and as reinforcement. Self-tapping screws for concrete are made of hardened metal and are additionally covered with special protection. The metal pins are strong and stable. In wooden structures, the beams are not threatened with warping.

But nevertheless, it is worth remembering that during the construction of a log house, such a property as protection against bending remains an important parameter. The tree is deformed, and then returns to its original position. But since metal is a rigid material and does not change with the crowns, the timber hangs, cracks are obtained through which cold penetrates. The pins themselves have high thermal conductivity, condensation may form, there is a risk of rusting "nails" and rotting wood.

Steel pins are praised for their ease of installation, because there is an option to use spring braces, which makes assembly more convenient.

The installation of the supporting structure (cobbled wall, window crown) can be carried out using the spring assembly technology. The device of this unit, due to the existing spring, allows a good connection of the rims. High sealing is achieved. The structure is mounted quickly and does not rot.

Wood

Such pins are loved by craftsmen in the construction of houses because the pins are resistant to bending loads, do not interfere with the natural shrinkage of the log house. A truly reliable connection is achieved through gradual integration with beams and logs. If wooden "nails" are used, exceptional tightness is created.

Wooden pins can be made independently, while manufacturers offer high-quality larch, oak, beech, birch or pins from ash, coniferous trees. The cost may vary depending on the breed from which the pin is made.

Plastic

Plastic pins have less bearing capacity. This material does not take into account wood shrinkage and shrinkage.

Flexible plastic - a softer connection than metal pins, but the fasteners are of high quality, and if you choose the right size in accordance with the loads, the walls will not loosen or sag.

Dimensions (edit)

When choosing wooden pins, which connect two crowns, attention is primarily paid to the thickness of the pin.The length does not really matter here.

In order for the "nail" to withstand the load and not break, according to the regulations of the established standard, the diameter of the round wooden dowel is at least 1/6 of the thickness of the log. Calculations are performed following this rule. The difference between the hole in the wood and the dowel in size should be plus or minus 0.5 mm. In addition, it is noted that wood is a material of natural moisture, the diameter of the hole made increases.

When assembling home furniture, small dowels with a diameter of 0.8-1 cm may be needed. They will reliably connect the parts.

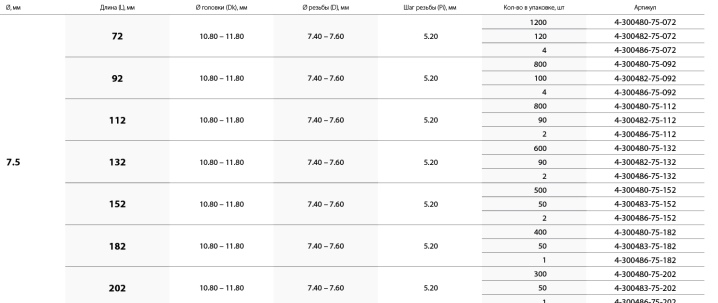

Since the dimensions of objects that are fastened with self-tapping screws are mainly determined by the length of the fastening element, the size of that part of the element that will be screwed plays a decisive role in working with such connections. With an increase in the load, this part of the self-tapping screw should increase. The spread in size is from 50 to 200 mm inclusive.

The purpose of the types of dowels for concrete, as is already known, is different, because this or that type of coating determines the quality and properties of the screw. Black self-tapping screws of any length common in construction have one diameter - 7.5 mm. Yellow copper-plated and with zinc protection in thickness range from 2.5 to 3.5 mm. The last two species are shorter than black ones.

The size of pins for connecting logs from 140 mm (diameter) - from 30 mm. In critical construction, such as the construction of log cabins, cottages or even baths, it is better to use pins that would meet the load created on them.

Installation features

So, when you have already decided on the choice of the type of dowels suitable for the material and performed the necessary size calculation, you can install the fasteners.

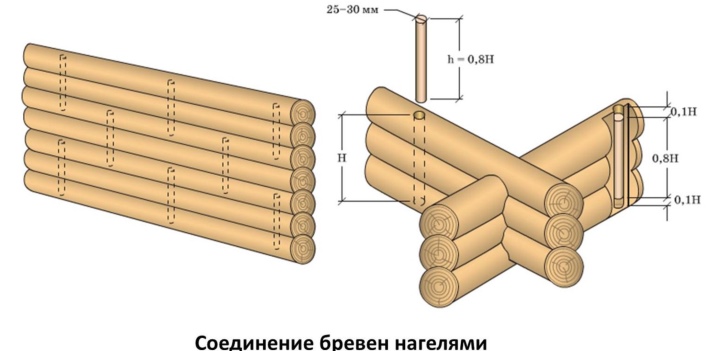

The assembly takes place in the following order. During the construction of a wooden house, points are outlined in the center of the logs in which holes for the dowels will be drilled. The distance from one pin to the next in the log is one and a half meters.

When installation work is carried out, the installation of the dowels always occurs at an angle of 90 degrees to the supporting material (brick wall, crowns). Therefore, the timber is drilled vertically. It is very easy to make a hole in wood using a special low speed drill with beam drills.

The drill diameter matches the pin diameter exactly. Before making the first hole, do not forget to retreat from the end of the log 20-30 cm.

To screw a self-tapping screw into concrete, a Torx T30 bit is used, a screwdriver or hammer may be needed. However, power tools that drill at high speeds and heat the fragile screw are avoided. The dowel is hammered into the hole in the crown with a hammer and recessed so that after installation there remains 2-3 cm of free space on top.

The placement of pins in the construction of houses from a bar is performed in a checkerboard pattern. It is wrong to fasten the crowns, placing the pins one under the other. Choose for work smooth pins without any knots, from wood of the first grade, treated with soapy water, an antiseptic. The moisture content of the fasteners should be lower than that of a wooden structure - this is important for a secure fit and withstanding the displacement of one beam relative to another.

Having completed the correct installation of the dowel, you can count on its long service as a connecting element in any project.

How pins are used in the construction of houses, see below.

The comment was sent successfully.