Drill sets for metal: types and selection criteria

The quality of construction, repair and installation work depends not only on the tools used, but also on the correct selection of consumables. This is especially true when drilling, when a poor-quality tool can lead to injuries. Our article is devoted to the most popular metal drill sets, as well as the main criteria for their selection.

Peculiarities

Drills consist of three conditional elements:

- cutting part - is located in the front of the product and directly provides the formation of a hole in the material;

- working part - located behind the cutting and must ensure the removal of chips from the place of work;

- shank - located at the back and intended for fastening the product in the tool (drill).

The hardness of the drill must be higher than that of the metal to be processed with it (at least 62 HRC). Drills must have a certain sharpening angle:

- for processing steel, cast iron and hard bronze - from 116 to 118 °;

- for works on soft bronze and brass - from 120 to 130 °;

- for copper - 125 °;

- for aluminum processing - 140 °.

Classification

Drills for metal are usually classified according to the following main characteristics:

- by design;

- by material;

- to size.

The sets of these products may also differ in the composition of the drills they contain. Let's consider each of these classifications in more detail.

Design

There are currently 4 types of drill designs.

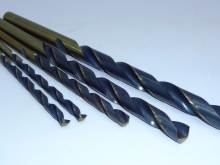

- Spiral - cylindrical parts with a sharp tip and a spiral groove along the length.

- Stepped conical - each step on them corresponds to a certain diameter of the resulting hole. One drill can produce holes of different diameters, the depth of this hole will depend on the selected diameter. Such a tool is much better centered than a spiral one.

- Flat (feather) - are distinguished by a relatively low price, good alignment and high reliability. They can only be used to produce holes of relatively small diameter and shallow depth, since they very poorly evacuate chips from the working area.

- Drill bits - this option is used when it is necessary to obtain a large diameter hole in a relatively hard material.

There are special options for twist drills.

- Elongated - are used to make holes, the depth of which is more than 5 times the tool diameter. They are distinguished by the presence of a double spiral channel, which is used to supply coolant to the cutting part.

- Centering - special products for creating holes for centering drills of large diameters (usually on machine tools). They differ in small length and diameter ranging from 0.25 to 5 mm.

- Threaded - cut a thread inside the hole.

- Left-handed - used for dismantling hardware.

- High precision - allow you to perform work with a high class of accuracy.

The drill shank is:

- cylindrical (found in both Soviet and new domestic and foreign products);

- hex (typical for new foreign models);

- conical (the rarest format, more often found in CNC machines than in hand tools).

Material

According to the metal from which the borax is made, the following varieties are distinguished:

- steel (usually made of high-speed steel);

- from alloy steels (titanium and cobalt additives are common);

- carbide (usually carbide is used in the form of a coating or replaceable inserts in the cutting part).

The size

GOST 10902-77 distinguishes the following standard sizes of drills:

- short - differ in diameter from 0.3 to 22 mm and length in the range from 20 to 131 mm;

- elongated - with the same diameter as the short ones, they have a length from 131 to 205 mm;

- long - their length is from 205 to 254 mm, and their diameter is in the range from 1 to 20 mm.

Composition

The following standard sets of drill bits for metal working are the most common:

- 3 pcs... - usually step drills with diameters of 4-32 mm, 4-20 mm and 4-12 mm are supplied in this way;

- 5 pieces... - usually this is how inexpensive twist drills of small diameter are sold for domestic needs;

- 6 pcs. - similar to the previous version;

- 8 pcs. - semi-professional sets, most often in the range of diameters from 3 to 10 mm;

- 13 pcs... - an extended semi-professional set, found in versions of different diameters with a step from 0.5 to 2 mm;

- 15 pcs. - similar to the previous one;

- 19 pcs. - a professional set, which usually contains drills with a pitch of 0.5 mm;

- 25 pcs. - contains all diameters applicable for hand tools, namely - 1-13 mm with a step of 0.5 mm;

- 29 pcs. - extended professional sets, most often in the size range 1-15 mm or 3-16 mm.

What does the color say?

Contrary to popular belief, the color of the drill does not provide an unambiguous indication of its material. So, gray tools can be made of low-quality steel (therefore, many craftsmen advise to avoid buying them), however, gray color can also be acquired with high-quality steel as a result of oxidation. Therefore, before you refuse to buy a set because of the gray color of the components included in it, it makes sense to study its labeling.

The same applies to black drills - this color can be a result of nitriding, oxidation or steam treatment, as well as coating. But the presence of a golden hue indicates that the product is made of hardened and tempered steel. Such products will have a slightly lower hardness, but much greater strength and reliability.

If the instrument has a rich golden color, then it contains titanium. This element improves the hardness and strength of the material, and also reduces the coefficient of friction of the product against the surface, due to which the drill lasts longer and heats up more slowly.

Standard markings

Both according to GOST and according to ISO standards, the marking is applied to the tail of the drill closer to the end. It without fail indicates:

- diameter (on Soviet and Russian products in millimeters, on goods from the United States - in inches);

- accuracy class (A1 - highest, A and B - lower);

- material.

The marking system adopted in the Russian Federation includes standard designations for steels:

- P9 - high speed steel containing 9% tungsten;

- R9K15 - the previous version, alloyed with 15% cobalt;

- R6M5 - contains 6% tungsten and 5% molybdenum;

- R6M5K5 - additionally contains 5% cobalt;

- R0M5F1 - tungsten-free high-speed steel, has a lower price and slightly lower hardness.

P9 tools are best used for simple work, while cobalt options are suitable for processing hard heat-resistant metals. In foreign marking, high-speed steels are designated by the letters HSS.

Popular manufacturers

Currently, the most popular on the Russian market are drill sets from three groups of manufacturers. The most expensive and high-quality products are manufactured in the USA, Germany and other European countries. The sets of Russian manufacturers differ in slightly worse quality and at a lower price. The most budgetary options are made in China. Let's consider each of the product groups.

USA and Europe

- The rating of western manufacturers of drill sets is traditionally headed by the German company Bosch, which produces sets of various compositions. The most popular one is Bosch 2607017154containing 25 drills in the range of diameters from 1 to 13 mm. The main disadvantage of these products is that due to the sharpening angle, they do not cope well with aluminum processing.

- The products of the company also show themselves well. Ruko with carbide coating... This company is one of the few that produces both spiral and crown products. The company also boasts unique sets containing 50 and 170 items.

- For drilling in hard metals, the company's kits are well suited Haisser. Unfortunately, the company almost does not produce sets containing drills with a diameter of more than 10 mm.

- But the firm DeWalt offers drills up to 13 mm in sets of 28 pcs. At the same time, they are distinguished by a good price-performance ratio and ensure that there are no defects at the edges of the hole.

- Sets from a German company are also popular Hawera, in particular HSS-C SpiralBohrer GQ-32692 25-piece (1-13 mm) HSS coated with titanium nitride.

- If you want to save money, you can purchase a universal set Irwin TurboMax, consisting of 15 items. Its cost is almost 2 times lower than that of professional kits. Please note that these drills can only be machined with these drills when cooled with liquid.

Russian sets

Among the modern domestic brands, the companies Zubr, Attack and Enkor have shown themselves well:

- sets "Bison" 20 pcs. differ in cross-shaped sharpening and a relatively low price (about 1000 rubles);

- the same cost and sets of "Enkor" for 19 items in the range from 1 to 10 mm, differing in the presence of a carbide coating of the cutting part;

- a professional set from "Ataka" will cost several times more, but it will allow you to process even hard steel grades.

Finally, the old Soviet victorious drills, which are actually made of VK4-VK 10 carbide-coated steel, often outperform modern versions of conventional high-speed cutters.

Chinese brands

The most popular Chinese kits are made by Matrix and Stayer.

- For less than 600 rubles you can purchase a set 19-piece Matrix with diameters from 1 to 10 mm (step 0.5 mm) in a metal case. These drills are made of high-speed steel R4M4X2, which makes it possible to recommend such a set for DIYers who perform irregular work with relatively soft types of metal.

- If you want to work with hard types of steels, you should pay attention to the kits Matrix with titanium nickelide coating (they can be distinguished by their rich golden color). A set of 13 products with a diameter of 1.5 to 6.5 mm will cost about 300 rubles.

- Stayer offers a wider range of PROFI kits, made of steel R6M5. The assortment of the company includes sets of the following composition:

- 3 pcs. (2-4 mm);

- 5 pieces. (2-6 mm);

- 6 pcs. (2-8 mm);

- 8 pcs. (3-10 mm);

- 10 pieces. (1-10 mm);

- 13 pcs. (1.5-6.5 mm);

- 19 pcs. (1-10 mm).

Products of popular Chinese brands are focused on household use, therefore, it is better to purchase goods from Russian and Western firms to work in a workshop.

Advice

Before you go shopping, it is worth clarifying the following details:

- what kind of metal you want to process;

- what tool you plan to use (drill, machine, screwdriver, hammer drill, and so on);

- what will be the speed and mode of drilling;

- how often you will perform work;

- what is the diameter and depth of the hole that you plan to make.

When choosing a set, you need to clearly understand which hole diameters you will need to make. If you are going to work in a workshop, you will need a professional kit, and a kit from 1 to 10 mm will be enough for a home craftsman.

Store the purchased kits in their "native" packaging in a warm and dry place. If organizing storage in low humidity conditions does not work, you can try to store them in a rag soaked in oil.

For an overview of 13 pcs Intertool metal drills, see the following video.

The comment was sent successfully.