How to choose an electronic micrometer?

In work related to accurate measurements, a micrometer is indispensable - a device for linear measurements with a minimum error. According to GOST, the maximum permissible error of a serviceable device with a division value of 0.01 mm is 4 microns. In comparison, a vernier caliper can provide a measurement accuracy of up to 0.1 mm or up to 0.05 mm, depending on the model.

Peculiarities

According to the principle of operation, micrometers are divided into mechanical and electronic, the latter are also called digital. According to the field of application, these devices are classified as:

- smooth (MK);

- sheet (ML);

- pipe (MT);

- wire (MP);

- groove;

- blade;

- universal.

There are varieties for measuring rolled metal products and measuring depth. To choose the right digital micrometer, you need to proceed from the required accuracy and know the principles and features of each of the listed types of measuring instruments. There are a number of important factors to consider when choosing.

Principle of operation

Before buying a tool, you need to know how it works and what are the functional differences between different modifications. The micrometer is a construction of the following fundamentally important units.

- Brace. Made of high hardness alloy. Its size determines the maximum clearance that can be measured with this tool.

- Heel. The reference point is pressed directly against the surface of the measured object.

- Micrometric screw. Its distance from the heel is the desired length.

- Drum. When turned, the micrometer screw moves towards the heel (or away from it).

- Friction clutch or ratchet. When clamping the measuring object, it allows you to control the pressure on the micrometer screw.

For digital devices, the length values are displayed on the dial, so they are most convenient to use. The desired distance is determined by the sensor. The power supply to it, as well as on the display, is supplied from the accumulator (ordinary battery). Not inferior to mechanical options in accuracy, these types of instruments allow you to work faster and much easier to calibrate (tare the device). To calibrate (set the scale to zero), just press the corresponding button.

When choosing a micrometer, decide in which system of measures you will need to work. Some manufacturers offer a function to switch between metric and imperial systems.

Features and comparison of micrometer types

The digital micrometer has strong advantages over other types that have made it popular in the market. But there are also disadvantages to keep in mind when choosing. Let's list the main advantages.

- It is convenient and easy to use and allows you to make accurate measurements.

- Reading the readings from the display without having to calculate the divisions on a conventional scale greatly speeds up the work.

- There are also additional options. Some instruments have a digital menu for setting measurement parameters. In addition, they can store many values in memory and compare them with each other. This function makes it possible to make a series of measurements and compare indicators much faster and more convenient. One of the types of mechanical micrometers - lever, has a similar function, but this is its main purpose, and it is not suitable for other purposes (unlike electronic).You may consider purchasing this tool if your main work need is for serial measurements of some parts and comparison of values.

Let's move on to the disadvantages.

- Batteries discharge over time and must be replaced.

- Care must be taken during operation to avoid damaging the screen.

- The sensor can also be damaged by accidental impact.

- Devices equipped with electronics have a shorter service life than mechanical ones, and are more expensive.

Areas of use

Each model allows you to solve its own range of tasks, which is an important factor when choosing a tool. For example, you need a micrometer for your everyday household needs - for your home or garage. At the same time, you want to get a more convenient and functional tool than the usual vernier caliper. Then a standard sleek digital micrometer is perfect for you.

For workers in the water sector, it will be useful tube micrometer. MT allows you to quickly and accurately determine the wall thickness of any pipe (the inner diameter of which is 8 mm or more). In workshops for the production of roofing sheets and other easily deformable metal materials, a sheet micrometer is indispensable. It features large clamping jaws in the form of round steel plates.

In the production of parts and workpieces of complex shapes, for example, gears and gears, tooth measuring micrometer. There is another type of metal product, which is very widespread, but requires a special measuring device - ordinary wire. In order to measure its thickness, use wire micrometer.

If you are dealing with more than one type of measured surfaces, but are working with many complex parts of various shapes, then you should start universal micrometer. It is designed in the same way as usual, but it comes with a set of special inserts that are installed on a micrometer screw. Many other types of micrometers are omitted here, such as grooved or prismatic. Most of them are highly specialized. In most cases, the same tasks can be accomplished with more versatile digital micrometers.

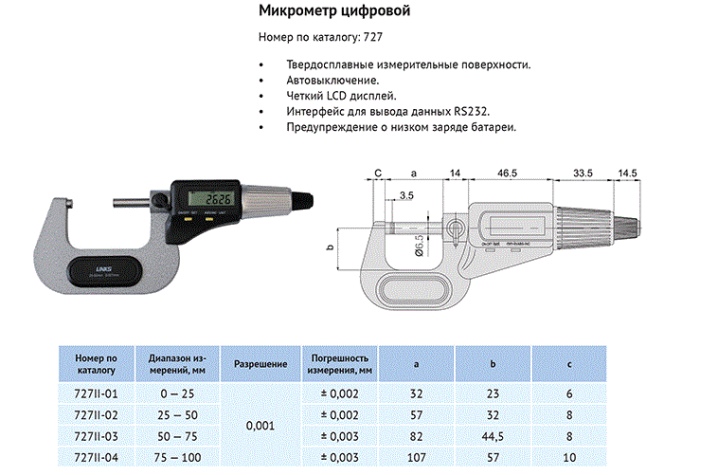

Measuring range

It is logical to choose a device that allows you to work with the most relevant length range for you. Therefore, each micrometer model indicates its range in millimeters in the form of a special marking. There is always a limitation of the micrometer screw travel in the micrometer design. The maximum linear length that can be measured with it is always less than the distance from the heel to the stopper.

For common needs, they are more often used modifications with a range of 0-25 mm (for example, a smooth micrometer will have a marking of the MK 25 type) and 0-75 mm. GOST provides for other basic ranges up to 900 mm inclusive. With an increase in the range, the acceptable margin of error also increases slightly. For example, MK 25 measures with an accuracy of 2 microns. For micrometers with the widest range (600-900 mm), the margin of error can reach 10 microns.

Devices with a range of more than 50 mm have a setting gauge that allows more accurate measurements by setting the indicator to zero division. This mechanism is explained as follows. The larger the measurement range, the more significant the deformation of the part, and, consequently, the error. In order for the deformation to influence the measurement result as little as possible, two types of indicators are used.

- Sentinels - have a scale with a division value of 0.001. Allows you to adjust the pressure on the micrometer screw so that the deformation is not too great. During the measurement, the drum should be rotated until the indicator arrow is at the zero division of the scale.

- Digital - they work on the same principle, but they allow you to set the indicator to zero in a more convenient and faster way.

The indication is especially relevant when measuring the dimensions of parts of low rigidity.

Accuracy class

The most important indicator that you should pay attention to when choosing a micrometer is the accuracy class. There are 2 classes of accuracy defined by GOST: 1st and 2nd. As stated above, the accuracy limits are range dependent. The first class of accuracy provides a margin of error from 2 to 6 microns. The second is from 4 to 10 microns.

Popular models

There are a number of popular brands that make high quality micrometers. Among foreign manufacturers of digital micrometers, the following are leading.

- Swiss firm Tesa. The line of digital micrometers Micromaster has earned the trust of professionals, the indicators of the devices really correspond to the declared accuracy (up to 4-5 microns).

- Japanese micrometers Mitutoyo, according to user reviews, are leaders in the quality of performance. In this case, it is recommended to purchase them from an authorized dealer.

- Carl Mahr. The German instrument has always been of the highest performance, and this brand's digital micrometers are no exception. They have the same level of quality and functions as those mentioned above: precision, wireless data transmission, professional dust protection.

There are 2 main factories among domestic manufacturers: Chelyabinsk instrumental (CHIZ) and Kirov instrumental (KRIN). Both supply digital micrometers with the special designation MCC. Finally, the question remains whether it is worth purchasing Chinese-made micrometers. Keep in mind that the performance of instruments priced close to $ 20 usually does not match the stated accuracy.

They will not be able to make measurements with an accuracy of thousandths of a millimeter. So, when buying from a Chinese brand, you should be careful not to try to save too much.

Advice

So, now you know everything there is to know in order to choose the right micrometer for your purposes. First of all, you need to understand the principle of operation of the device and imagine how its main technical units function. Then you can visually assess the quality and convenience of the tool. If you buy it from a dealer, then most likely you will not encounter a marriage. However, check to see if the drum turns easily and if the micrometer screw gets stuck during the stroke. It can jam when dust gets in, so it is recommended to purchase a special tube-case together with the micrometer and carry the device in it.

See below for an overview of the electronic thermometer.

The comment was sent successfully.