Everything you need to know about countersunk screws

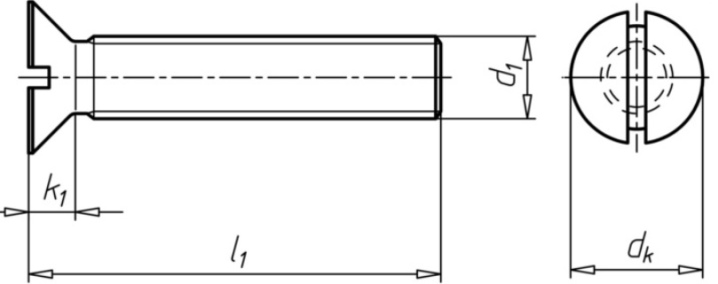

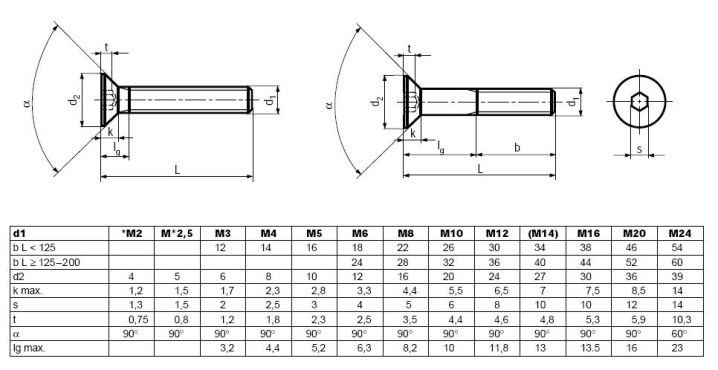

Countersunk screws are widely used in various fields of activity, from furniture assembly to renovation and construction work. Certain standards have been established for this type of product: GOST R 50403-92, GOST 17475-80 and GOST 17475. They are used to produce bolts with an internal hexagon M6 and self-tapping M3, M8 and other types of products equipped with a countersunk head.

Description

A countersunk screw is a type of metal product designed to connect parts. Like a bolt, it consists of a head and a shank that does not have a sharp end. Installation can be through or blind. The head is recessed into the material or structure without remaining on the surface. Its main part is most often conical, allowing for flush installation, has slots:

- for a hex wrench;

- for a Phillips or flathead screwdriver.

The screw thread is formed by the knurling method, according to its design it can be full or partial. Products can be made of carbon and alloy steels, non-ferrous alloys, stainless metals. According to the degree of strength, 11 classes of hardware are distinguished, in terms of accuracy only 2: A and B. Depending on the operational requirements, the hardware is covered with a protective anticorrosive shell or left without it. Most often (in the case of ferrous metals), processing is carried out by galvanizing or applying a zinc-lamellar coating.

It is important to know: self-tapping screws also belong to the category of self-tapping screws, they can have a countersunk head.

Their dimensions, characteristics and installation correspond to those indicated for a specific type of product. The main difference lies in the end part of the product: it is sharpened or looks like a drill, and the thread is applied with a certain pitch, which makes it possible to effectively fix the product in materials with different degrees of density.

Products of this type are characterized by the following features:

- material - carbon or stainless steel;

- anti-corrosion zinc coating;

- splines of types Torx, Pz, Ph;

- the end is blunt or sharp;

- length 9.5–32 mm with a diameter of 2.2–6.3 mm.

Self-tapping screws of this type are produced according to DIN 7982.

Applications

The use of countersunk screws is relevant for various fields of activity. Due to the wide range of diameters, they are in demand even in the watch industry, where special requirements are imposed on the size of fasteners. Among the most common applications for countersunk screws are several.

- Instrumentation. They are used to assemble parts in various types of consumer and industrial electronics.

- Mechanical engineering. The countersunk head is absolutely indispensable in cases when it comes to particularly critical units, where any elements sticking out are absolutely unacceptable. In the automotive industry, these hardware is used in a hardened version that is resistant to temperature and mechanical deformation.

- Assembly of furniture, shelving, exhibition structures, any areas where fixing of sheet metal, plastic, wood-based panels is required. Hardware are mounted using additional nuts and washers, both in a blind way and through.

- Installation of housings and equipment parts. In the food, chemical and medical industries, an anti-corrosion version is used.Such screws are in full compliance with the sanitary and hygienic requirements and allow achieving the desired level of reliability without risking production safety.

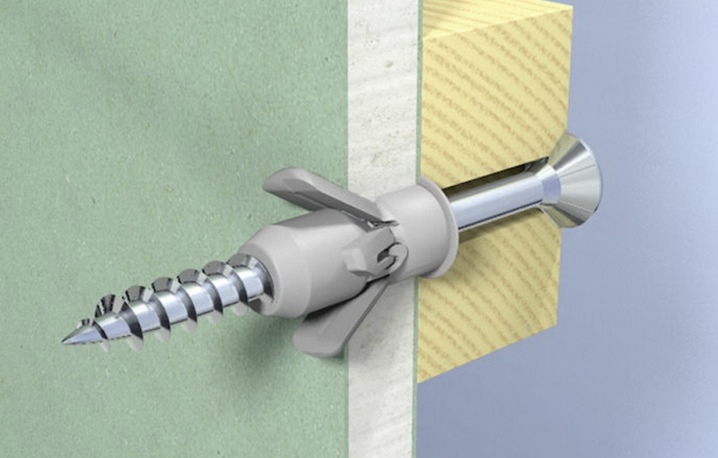

The areas of application for countersunk self-tapping screws are no less varied. Among the popular areas of their use are construction areas: the creation of one-piece fasteners in brick, concrete, wood, drywall. Often such hardware replaces dowels - their strength is sufficient to form a reliable support. When working with parts made of wood and plastic, pre-drilling is not performed for them.

What are they?

Absolutely all existing countersunk screws differ mainly in the type of head and slot. It is customary to consider self-tapping options separately, since they usually do not require additional efforts during installation. You can fix the hardware using a conventional screwdriver, without spending time on countersinking.

By the type of coating, products are classified into stainless and ferrous metals. The first version is made from non-ferrous alloys or equipped with a special coating at the production stage. The second can be additionally protected during operation with primers and other anti-corrosion compounds.

On sale you can find different types of hardware suitable for flush mounting.

- With a half-countersunk head. In such products, part of the head remains above the surface of the part, not ensuring full immersion into the thickness of the material. This is quite acceptable in those cases when it comes to not too stressed structural elements.

- With slot for flat screwdriver. The simplest and least common option. Today, such screws can be found in ship equipment, in watch movements, and measuring instruments. They are easy to install, but the straight spline is not too tear-resistant.

- With cross recess. To install this type of hardware, you need a Phillips screwdriver or a screwdriver bit with a similar tip. In classic versions of screws, Phillips are not used very often, they are rather characteristic of self-tapping versions.

- With an internal hexagon. One of the most popular types of screws, its slot has a special shape and is called Torx. Its hexagonal recess inside diameter allows much more force to be applied when installed in contact with a key or bit. Some types of such hardware used in the assembly of furniture are called confirmatory.

Dimensions (edit)

The size range of products made in accordance with GOST R50403-92 extends to countersunk screws with straight and cross-recessed slots with a thread diameter in the range of 1–20 mm, which is reflected in the marking. Among the current standard sizes, one can single out M1, M2, M3, M4, M5, M6, M8, M10, M12, M14, M16, M18 and M20. And also there is an extended range in which there are intermediate diameters. These include:

- M1.2;

- M1.4;

- M1.6;

- M2.5;

- M3.5.

The standard screw length range is 2mm to 120mm. The most common are the following sizes of countersunk head screws with straight or Phillips recess: M3X5, M3X50. Sometimes on sale products are simply labeled by diameter and length - 5X120 mm, 4X70 mm. For screws in the size range over M4, length indicators are characteristic of 40, 45, 50, 60, 70, 80, 90, 100, 110 and 120 mm.

Features of use

The main advantage of using countersunk screws is the ability to get a flat and smooth surface on the part without significant height differences. In the furniture industry, after assembly with such hardware, decorative plugs can be fixed in their slots, which completely hide the area of the mounting hole. Anti-corrosion coated products are suitable for outdoor use in humid environments. Ferrous metal options have a limited range of applications, with the exception of stainless steel hardware.

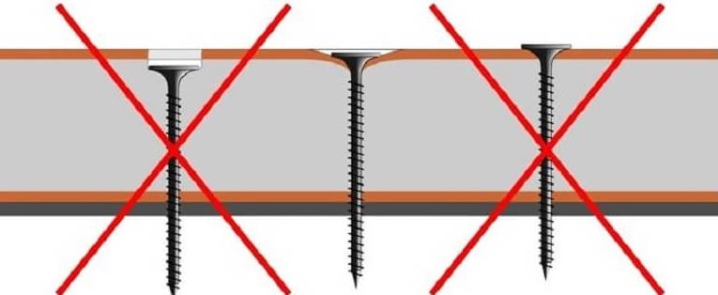

For countersunk head screws made in accordance with GOST, the holes must be pre-prepared for installation. For this, a number of operations are performed to ensure maximum connection reliability. In the case of conventional - not self-tapping - screws, the work process is divided into certain stages.

- Holes with a common diameter are made in the parts to be joined.

- An internal thread is cut or a sleeve is installed with it.

- The mounting part is countersinked. The dimensions and depth of the tapered bore must match those of the screw itself.

- Tightening the fastener until it is completely immersed. The head should be sunk into the material. Work is done with a screwdriver or a screwdriver with an appropriate attachment.

In the case of self-tapping screws, no pre-drilling or countersink is required. A power tool is sufficient to ensure that the required effort is applied.

When working with self-tapping screws equipped with a countersunk head, you also have to follow certain rules. Strict perpendicularity is important when the elements are located relative to the axis of the surface of the material itself. The size and type of the bit are carefully selected, since it is important to ensure a fairly tight fit of its working surface to the walls of the slot. Failure to follow these recommendations may result in screw breakdown.

How to properly countersink the countersunk screw holes, see the following video.

The comment was sent successfully.