Mastic MGKP

For humanity, electricity has become a useful and everyday thing. It is from this type of power that a large number of equipment, devices and everything that is in mass demand work. But, unfortunately, electrical wires are subject to fire hazards, which is why there is a risk of malfunctions. To avoid this, people are increasingly using MCGS mastic.

Description

This material has a large number of advantages and is divided into two types:

- waterproofing;

- fire retardant.

The first type, as the name implies, prevents any moisture from entering the places where the wires will be. The tool itself consists of a pasty viscous substance that is applied to the desired area in the room. As for the principle of operation, it consists in the fact that in the event of sparks or an ignition source, prevent this area from spreading the high temperature to other parts of the communications.

Simply put, the sealing compound helps prevent flammable situations as well as protect cable systems from other unpleasant physical influences. The first type is characterized by special properties that help when operating in difficult conditions, for example, places with high humidity or mold. In addition, the waterproofing properties are to prevent the formation of dust, dirt and other substances that can negatively affect the operation of the cables over time.

The fire-retardant advantages of the MGKP mastic are expressed in the fact that this material has an extended temperature range (from -50 to +70 degrees), within which the substance retains all its properties. Simply put, by sealing certain passages, routing modules and other cable locations, you will create a protective barrier that will allow communications to work more reliably and not be exposed to harsh conditions, both physical and technical.

One of the advantages of fire-fighting mastic is its ease of use. This substance is produced immediately ready for use, and the user only needs to apply the substance to the desired location. It is also worth mentioning about the long service life, which, as a rule, is equal to 20 years. During this long period of time, the mastic (with proper application and correct initial use) does not lose its positive protective characteristics.

It is also important to remember that the substance is versatile and resistant to various negative factors, such as chemicals. This mastic does not contain any solvents, which makes it safe to use in any environment. Consumers note a high degree of adhesion to metal, concrete and other substances, which greatly facilitates the use of this substance even with a wide variety of materials used in the construction industry. Manufacturers claim to have a high degree of sound insulation and versatility when painting and other effects on the mixture.

Holes and lines, when sealed with this component, do not require any additional intervention in order to maintain the properties of the mastic. Other advantages include gas and water resistance. This point is important in case of a high level of condensation and evaporation in the room.

In fact, there are a large number of mastics, but MGKP has a certain field of application, which involves the protection of network and other cables, as well as large penetrations connected to wide communication schemes.

Appointment

Taking into account the unique and universal properties and characteristics, the purpose of this mastic depends on the specific situations when you need to protect cables and wires from negative consequences of various types. First of all, the most important area of use of this substance is the use in structures equipped with or connected to power supply. Such structures include server stations, technical buildings associated with networks, as well as special places that act as storage for units operating due to the presence of engines and other similar components in them.

The best result from the use of mastic can be obtained when processing cable penetrations with a diameter of up to 100 mm and a cross-section of 100x100 mm. In addition, this substance is also used to seal cracks, chips, seams, joints and other places near which cables and equipment can be installed. As for other types of mastics, their scope of application depends on the characteristics of each type.

For example, there are types of mixtures that people use to treat stove or boiler equipment, and also use when lining the lining, thereby protecting it from the effects of various gases and chemicals. When they interact, a large amount of heat is generated. The temperature range of these substances can reach thousands of degrees, which is caused by the special components that make up this material. There are also special waterproof mixtures used for underwater communications. As a rule, they are included in the composition of concrete, which does not undergo negative consequences even if it is constantly in the water, for example, during the construction of bridges, pillars, and supports.

There is also an adhesive mastic used for laying ceramic tiles, stone, glass, panels and fireclay products. Thus, not only the substance itself will be protected, but also the area around it. Adhesive mastic is used in decorative finishing and restoration, when it is necessary to prevent the negative consequences of the external environment on those types of materials that may soon be processed. The roofing type of mixture is popular when interacting with actively burning substances, for example, bitumen, which is used to treat roofs.

In order for these components to be protected from fire or wired communications located on buildings, the substance forms a special layer, when heated, it begins to increase its size, thereby preventing the possibility of a fire source.

How to use?

Considering the fact that MGKP mastic is supplied ready for use, you will not need to carry out any processes for creating a mixture, kneading it and everything else inherent in a considerable amount of building materials. Installation of cable penetrations with this material is carried out in several basic stages.

- Cleaning the hole from dirt, dust and other substances, the presence of which may interfere with the effectiveness of the mastic.

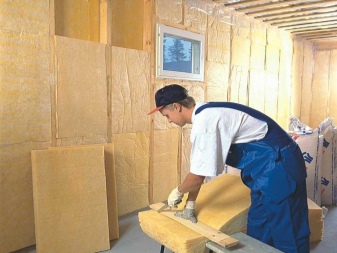

- Laying of mineral wool, which will serve as the basis for filling.

- Filling the formed voids with the substance.

- Leveling the mastic with a spatula so that it is as flat as possible relative to where the hole is made.

- Installation of a special marker, thanks to which you can determine in the future where the mixture was used. These places should be checked periodically, and if the construction of the mastic is broken, then repeat all the previous procedures in a new order, while avoiding past mistakes.

Do not forget about safety, information about which is in the instruction manual.

See the video below for the MGKP mastic.

The comment was sent successfully.