Varieties and rules for choosing welding masks

Any type of welding is considered a hazardous activity for the health of the master. When cutting or joining metal products, sparks, infrared and heat radiation are generated that can damage the skin and cornea of the eyes. For maximum safety, the welder must use special personal protective equipment (PPE): masks or shields.

Peculiarities

A protective mask is a mandatory attribute of welders' equipment. It protects the visual and respiratory organs, as well as the skin from various harmful effects that arise during the operation of welding equipment. By refusing to use such PPE, the employee exposes himself to the threat of partial or complete loss of sight.

All modifications of masks are equipped with a viewing screen designed for the welder to observe the work. Usually it is covered with tinted polycarbonate glass or plastic. There are more expensive and improved models that use filters that react to the flow of light energy.

The benefits of masks include:

- security effective protection of eyes and skin from thermal and mechanical influences;

- easedue to which the products do not exert an additional weight load on the welder's head and neck;

- ease of use;

- wide range of models with different design features and functionality (both simple budget masks and more complex solutions equipped with LCD screens are available for sale);

- long service life subject to careful handling.

The disadvantages of some models of welding helmets include limited adjustments, due to which the product may not fit snugly to the face. According to welders, a significant disadvantage of professional PPE with additional options from well-known brands is considered to be too high a price.

Description of species

Welding helmets have their own classification depending on the design. The simplest personal protective equipment includes glasses and face shields. These are budget solutions designed for one-time or short-term work. Glasses are open and closed. The former have side protection; their filters are made of polycarbonate or mineral glass. The closed ones have fixation with the help of head holders. They have special ventilation holes to prevent fogging.

Points advantages:

- small weight, minimal dimensions;

- the possibility of welding in a confined space.

The disadvantages include the inability of glasses to protect the respiratory organs, skin of the face and neck from harmful effects.

Face shields provide greater safety for the welder compared to goggles, since they are able to completely cover the face. Products come with a handle - they must be held by the face during work with the help of a holder. On the one hand, the shields are easy to use, as they can be quickly removed to assess the quality of the suture. On the other hand, when holding PPE 1, the welder's hand will be busy, which makes it impossible for him to hold the part during work.

Masks are also classified into universal, with lifting light filter or with air filtration. The most advanced PPE are considered "Chameleons". All of these types have different pros and cons.

Standard

This group includes ordinary masks, made of plastic. They are lightweight (no more than 0.5 kg) and have an unreliable budget mount. Versatile models look like a helmet. Such products do not require holding by hand - they are fixed on the head with the help of special fasteners with the ability to adjust in size. Universal solutions are easy to use - to assess the quality of the work performed, the master needs to fold back the mask.

If it is necessary to continue the process, she returns to her place by a sharp nod of her head.

The advantages of such models:

- low price;

- simple construction;

- the ability to adjust in 2 directions (horizontal and vertical);

- protection of eyes, skin of the face and neck.

The disadvantages of universal products include possible burns of the eye corneas during regular inspection of the quality of the suture - in this case, part of the radiation will negatively affect the organs of vision. Consumers also consider the drawbacks to be the rapid mechanical wear of the helmet and leather fasteners, and the frequent breakdowns of the fixing elements.

Depending on the intensity of operation, their service life ranges from 6 to 12 months.

With lifting filter

Such masks only provide for raising the light filter - to assess the quality of work, the foreman does not have to completely remove PPE from his head. When the light filter is folded back, the plastic shield and clear safety glasses will continue to protect the welder's eyes and skin. Such models, in comparison with the previous ones, provide a greater degree of protection.

"Chameleon"

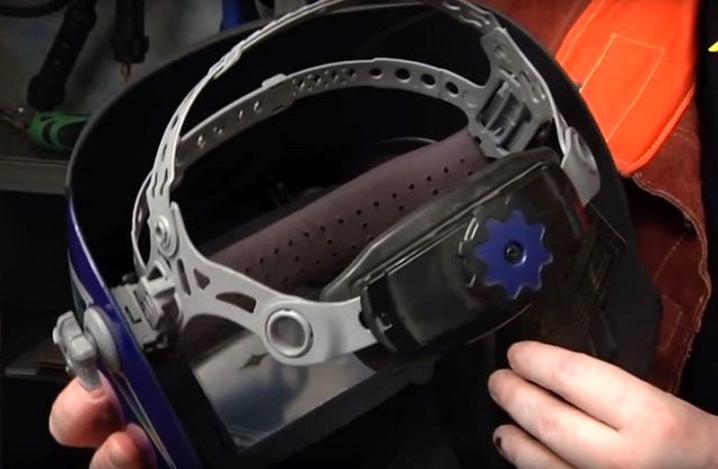

Best-in-class for performance, options, and performance. It is equipped with quality bindings that can withstand multiple lowering and lifting cycles. The design provides a soft foam liner to reduce the intensity of friction of the welder's head. "Chameleons" are distinguished by their unusual design, original shapes, they are often decorated with various stickers.

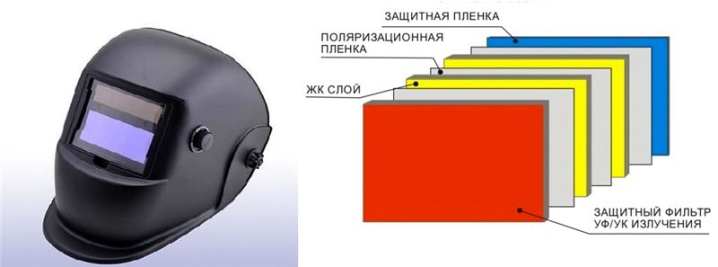

Their main feature is in the possibility of automatic change of the level of darkening of the viewing screen... It is achieved thanks to the provided light-sensitive sensors. When idle, the technician will see the environment through the viewing window, as through sunglasses. Due to this, in order to assess the quality of the imposed seam or other work, the master does not have to fold the light filter or completely remove the helmet.

This feature allows you to significantly increase productivity, prevent various "misses" and rejects.

The principle of operation of "chameleons" is simple - during the ignition of the welding arc, the sensitive sensors are automatically triggered. Result - instant darkening of the viewing screen to the optimal level. Upon completion of the work, the filters regain their light transmittance. For the functioning of such a system, the design of the "chameleons" provides a compartment for the batteries (in some models, the built-in battery acts as a power source). And there are also models equipped with solar panels that receive a charge from the energy emanating from the welded arc.

All "chameleons" there is a ventilation function. It prevents the screen from fogging up during work, which creates a comfortable environment for the welder. For welding in conditions of increased gas pollution, special masks with forced ventilation, equipped with a filtration system, have been created.

Advantages of "chameleons":

- complete protection of the neck, face, eyes and respiratory system from all types of negative influences;

- the ability to adjust the sensitivity, dimming and delay time (not available for all models);

- the ability to work in an aggressive environment;

- headband adjustment, thanks to which you can securely fix the mask on any head size.

Some models have the ability to turn on / off, which allows you to completely remove the blackout. Due to this feature, "chameleons" are used for grinding and cutting metal parts and structures.

The disadvantages of "chameleon" masks include them high cost, limited operating temperature range (-10 ... +50 degrees), expensive repairs in case of their failure. Such PPE must be stored away from sunlight at positive air temperatures, otherwise they will quickly fail. A significant drawback of models with a built-in rechargeable battery is the impossibility of replacing it.

With air filtration

These include specialized masks designed to protect the skin and eyes from harmful effects, as well as to protect the respiratory organs from the penetration of harmful vapors. They are recommended for use when working with various alloys containing harmful components. The devices can be used with a limited supply of fresh air or with a complete lack of ventilation in the room.

Such masks have complex design. It includes a welding shield complete with a light filter with a sensitive sensor, a filtration system and a supply of clean air. The masks fit tightly to the face, so that the respiratory organs are isolated from the penetration of gases harmful to health.

The main feature of products with forced air supply - tightness... Their casings are made of soft, fire-resistant materials, and there are adjustable seals in the neck area.

To ensure full breathing during welding, the devices provide portable filtration system. Air is supplied from the turbo unit by a fan. It can be powered by a built-in battery or solar panels. When the power source is discharged, the air flow becomes less intense - in this case, the welder will receive a sound signal, notifying the need to replace or recharge the battery.

Popular models

Welding masks are produced by domestic and foreign manufacturers. They offer a variety of models at different price points. Popular among home craftsmen budget PPE.

Here are the TOP of the best inexpensive masks.

- Interskol MS-400. The product is recommended for welding such as MMA, MIG-MAG, TIG and others. Has a manual dimming function. The power source is batteries and photosensitive elements. The shade of the filters is from 9 to 13 DIN. The disadvantages of the model include the small size of the viewing hole.

- Foxweld Corundum 5895. This is a PPE with an automatic light filter, equipped with 2 sensors. Designed for MMA, TIG welding. The model provides an external dimming control, welding and cutting modes. The product has a small weight - 370 grams, shade level 9-13 DIN.

- ROSOMZ NN-10 PREMIER FavoriT 10 5136. One of the cheapest face shields with tinted glass. It has tilt adjustment, the degree of shade of the filter is 10 DIN.

- Fubag Optima 4-13 Visor... Chameleon mask suitable for both amateur and long-term professional welding. The maximum degree of shading is DIN 9-13, the dimensions of the inspection hole are 100x65 mm. They differ in almost instantaneous darkening speed (0.04 s). Power source - lithium or solar battery. Mount type - headband. There is an option to test the light filters yourself.

The most expensive models - professional masks from German, American and other brands. The rating includes reliable and high-quality devices that have received the highest consumer ratings.

- Kedr K-714T. Chameleon mask with a maximum shade of 13 DIN. The response speed of the photosensitive sensor is 33.3 μs.The model provides the function of adjusting dimming, sensitivity, delay time, "grinding" mode, ventilation system.

- 3M 501805. Chameleon mask with automatic light filter with a maximum shade level of 13 DIN. The product is equipped with additional side windows. The model supports the following options: adjusting the level of dimming, sensitivity and delay time. The "grinding" mode is provided.

- TECMEN TM 1000 with 4 optical sensors. The mask is equipped with a forced air system. It can be powered by a built-in battery or solar panels. The dimming level is 4-8 / 9-1 The large LCD screen is provided for comfortable operation.

- Speedglas 9002NC (American brand, country of origin - Sweden). Mask with automatic light filter with a shading speed of 0.1 m / s. The product is resistant to high temperature and mechanical stress, which increases its service life. Screen shading degree - 3 / 8-12 DIN. The mask is equipped with 2 optical sensors. Internal dimming adjustment provided

These models are suitable for all types of arc welding.

How to choose?

Before buying a welding mask, you should decide on the intensity of its use. Depending on the frequency of use, personal or professional PPE is selected. For infrequent use, budget face shields with a fixed shade level or goggles are suitable.

In order to choose the right protective mask, there are several important parameters to consider.

- Light filter... The choice of filter depends on the type of activity. In the case of professional work, it is recommended to give preference to solutions with automatic light filters - they independently adjust to the intensity of the luminous flux, setting the optimal level of shading.

- The degree of darkening of the glass, measured in DIN. The value of this indicator for various models ranges from 3 to 15 DIN. The larger it is, the darker the filter becomes.

- View area. Viewing screens come in different sizes - the more important the better the view. However, it should be borne in mind that light filters are afraid of mechanical stress. The wider they are, the greater the risk of breakage.

- Possibility to install diopter lenses under the mask... Diopters are designed to correct a worker's vision.

- Welding type... Masks are marked. Decoding of letter designations: E - the product is intended for electric welding, G - for gas welding, V - for auxiliary work, C - light filters "chameleon". You need to pay attention to the marking, since electric welding masks are not suitable for gas welding.

- Power supplies. For long-term work, it is preferable to choose PPE with 2 power sources, for example, lithium and solar batteries. When one of the sources is fully discharged, the second will continue to supply energy to the light filter, so that it will not turn off at an inopportune moment.

- Number of optical sensors - the more there are, the faster the filter will react to changing conditions.

When selecting, it is important to pay attention to the location of the adjustment system - it is desirable that it be on the outside of the mask. In this case, you can make adjustments to the PPE settings without interrupting the work process.

If welding work will be carried out in a polluted atmosphere, it is best to give preference to models with a forced ventilation system. It will provide an optimal level of comfort and breathing freedom.

Correct fitting also includes trying on the mask and checking the headband adjustment. PPE should not place significant stress on the head and neck.

Note! A certificate of conformity and a warranty card should be requested for the purchased product.

How to use?

Before starting work, you need to check the functioning of the automatic light filters. To do this, you can bring a lighter to the screen - the subsequent blackout will indicate the health of the PPE. If the light filter does not change color, you need to check the serviceability of the supply source and, if necessary, change the battery.

If manual adjustments are provided, the operating parameters must be correctly adjusted to suit the working conditions. Before using the mask, you must adjust it "for yourself" by changing the circumference of the headband, belt and other fasteners. After that, you can start to work.

Wipe the mask body and screen with a soft cloth after each use. In this case, you must not use abrasive or chemically aggressive substances.... Light filters must be protected from contact with liquid.

Possible malfunctions

The problems with most types of universal masks are in the failure of the light filter... Basically, breakdowns occur due to the careless attitude to PPE. To eliminate the malfunction, it is necessary to replace the damaged protective glass or light filter.

Chameleons have common problems in which the light filters are very dark or do not change the hue at all. In this case, it is recommended to replace the batteries.

If this does not solve the problem, you need to contact the service center.

For information on how to choose a welding mask, see the next video.

The comment was sent successfully.