Orthopedic beds with lifting mechanism

A healthy sound sleep is impossible without a comfortable sleeping place. To date, the most popular is the orthopedic bed with a lifting mechanism.

Features and Benefits

The appearance of the orthopedic bed is no different from the classic model, but it has its own design features. It consists of an orthopedic base equipped with a lifting mechanism, a linen box, a headboard and side bars.

An orthopedic bed with a lifting mechanism has many advantages:

- The main advantage of the bed is the base, with orthopedic properties due to the installed lamellas. Sleeping on such a bed is not only convenient and comfortable, but also useful. This base, together with the mattress, perfectly supports the spine. In addition, the lattice base is well ventilated, which means that mold and mildew of this structure is not threatened.

- A lifting mechanism built into the structure provides easy access to the laundry drawer. Its dimensions correspond to the dimensions of the base, and therefore the box has a significant capacity. In addition to bedding, other things can be folded here, and quickly retrieved if necessary. Thanks to the lifting mechanism, the contents of the box can be accessed from any side of the bed.

The presence of a box for linen in this design can significantly save space.

Things put away in a drawer do not require additional pieces of furniture: dressers, bedside tables and wardrobes, and this is a significant saving not only in the space of small rooms, but also in cost savings.

As a rule, such beds are produced by manufacturers not only in a double version, but also with smaller dimensions. There are single and one and a half sleeping models, suitable not only for adults, but also for children.

Varieties of mechanisms

Any model with a lifting base has its own characteristics that affect the operation process. The orthopedic base, depending on the model, can be reclined either horizontally or fixed in a vertical position, forming an acute angle of 45 degrees at the junction with the base. The method of lifting the base can be carried out using various devices.

As a rule, manufacturers equip models with only three types of lifting mechanisms:

- Coiled springs, constituting the basis of the transformation mechanism, are in demand due to the inexpensive price and ease of use. But in this mechanism, the springs wear out quickly due to frequent stretching and significant loads. The service life of the mechanism, as a rule, does not exceed five years, after which it needs to be replaced.

- Gas shock absorbers, helping to raise the base and fix it at the desired height, are distinguished by significant ease of use. Thanks to them, you can move the base without much effort. The gas system works smoothly and quietly and is able to lift the base together with the mattress, even if their combined weight is over 100 kg. To date, the gas transformation mechanism is the most reliable and high-quality, has a rather long service life of about 10 years.

- The easiest way to transform is manual lifting, carried out with a loop attached to the base.In order to raise the base and get to the box, you will have to remove the mattress and make significant efforts. Therefore, this mechanism is not very suitable for cots.

Base design

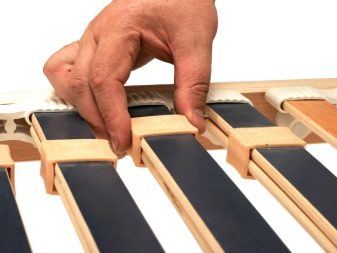

Any orthopedic base consists of a frame and a lattice. The frame can be either metal or wood. The lattice itself consists of lamellas, securely attached to the frame with the help of lat holders. Depending on the manufacturer and model, the lamella holders can be made of different materials. The rubber used as a material for lat holders is flexible and expensive. Plastic has a tough structure, but is more durable than rubber.

Lamellas are planks with a slightly curved surface on one side and are made of wood (beech, birch, walnut). The standard thickness of these planks ranges from 6-8 mm, and the width is 63 mm. The length of each lamella corresponds to the dimensions of the base. The distance between the slats is in the range of 70-80 mm, thanks to this value, the orthopedic effect is enhanced. These standards not only make the bed lighter, but also give it elasticity.

The orthopedic base is manufactured by manufacturers with the ability to adjust the stiffness.

Stiffness adjusters can be located directly on the lamellas themselves, allowing the base to be adjusted to the weight of a person, and there are also adjusters located in the head and leg parts of the base. Thanks to their presence, it is possible to change the angles of inclination in the upper and lower parts.

Most often, such beds are purchased for bedridden patients, because such an adjustment ideally meets all the vital needs of an immobilized person.

Selection Tips

There are several aspects to consider when choosing a bed. In addition to the design and compliance with the style of the interior, attention should be paid to the base and the mechanism of transformation.

- If the question is about buying a double version, then the transformation mechanism should be on gas shock absorbers. The base, in comparison with the single-bed version, has a greater weight, and the orthopedic mattress significantly increases the weight, and therefore, for the convenience of access to the box, it is better if the mechanism takes on the main load when lifting.

- To protect against injury, it is not bad if the bed is equipped with special bollards that protect against a sudden fall during the movement of the base.

- The lamellas should be free of large knots, cracks, chips and sharp rough edges. The base itself should not make any squeaks.

- The length of the legs that support the frame should vary within 24-25 cm. This value is the most comfortable base height for a person. The number of legs in different models is in the range of 4-7 pcs. The more legs, the more stable the base structure.

- Do not forget about the material of the bed itself. Solid wood is more preferable, since it is not only environmentally friendly, but also reliable, and therefore a bed made of natural wood will last much longer than a similar option made of chipboard.

You will learn how to assemble an orthopedic bed with a lifting mechanism from the following video.

The comment was sent successfully.