How to make a folding chair with your own hands?

An armchair is a piece of furniture that allows a person to feel comfortable and relaxed. But not all furniture of this kind is so convenient for transportation - it will not be possible to take it with you and use it wherever you want. However, this does not include a folding product, which has a small mass and dimensions. This chair is not so easy to find in stores, so craftsmen have found ways to make it with their own hands.

Tools and materials

So, in order to make a folding wooden chair for a summer residence yourself, you will need to have several things on hand. First of all, we are talking about the following materials and tools:

- roulette;

- pencil;

- metal ruler;

- screwdriver;

- saw;

- drill;

- sewing machine;

- scissors;

- construction stapler;

- fine-grained sandpaper.

As for the materials, then you will need to have on hand:

- bars for creating a chair frame;

- screws and bolts;

- metal hinges;

- wood (for a product of this type, you can even take chipboard and plywood).

In addition, you will need fabric for the upholstery of the chair. Its selection should be based on the needs of the owner. The most preferred options are welfot, flock, nylon, microfiber, jacquard, matting, polyester. You also need some foam to put it under the seat upholstery. This will make it much more comfortable to sit on the chair.

You will also need to have on hand drawings and diagrams of future furniture, where the progress of work and the sequence of actions will be described in as much detail as possible, and everything will be thought out to the smallest detail. You can either make them yourself, or simulate them using a computer program, or find them on specialized sites.

Manufacturing methods

It should be said that today there are a huge number of ways and methods of making chairs. It can be sliding, triple layouts, etc. - there are many options for sketches and models. For example, let's take two of the most common ways you can make a good garden chair.

Made of wood

One of the most popular options for making a chair is wood. It is relatively easy to make, durable and easy to carry wherever you want. It can even be installed in a PVC boat for a much more comfortable fishing experience.

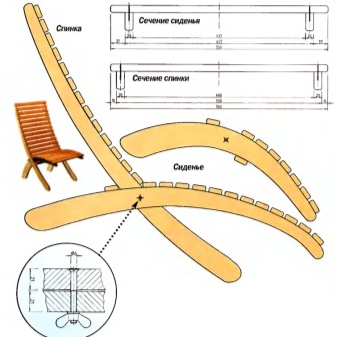

For to create such a chair, you will first need to apply the contours of the future elements of the structure in question to the plywood prepared in advance... After this is done, you need to take a jigsaw and cut out the parts strictly according to the marking.

Now the wooden blocks need to be divided into slats that will be used to create the back and seat. After that, we create jumpers from boards that have a slightly larger thickness. From the end side on the edges, we remove the chamfers at an angle of 45 degrees. To assemble the chair, you need to have 16 slats and a pair of persistent jumpers.

To create a seat frame, you need to have 9 slats and 2 plywood legs on hand. These parts are usually connected to each other using bolts and screws. Now we fix the outer rails with a pair of screws on each side. According to the same algorithm, the back of the product is assembled from 2 legs, 2 persistent jumpers, 7 rails, an upper jumper and a rounded edge with a hole in the middle.

It should be noted here that the entire assembly process of the chair should be checked with a square, and the slats should be aligned perpendicular to the plywood legs. This completes the assembly of the wooden chair.

It remains only to finish the chair with an antiseptic, stain and varnish in two layers, after which it can be used. You should also bring it to such a state that there are no chipping or other defects on it.

From an old clamshell

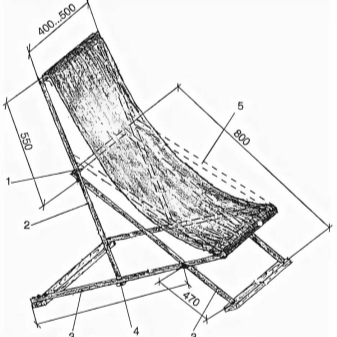

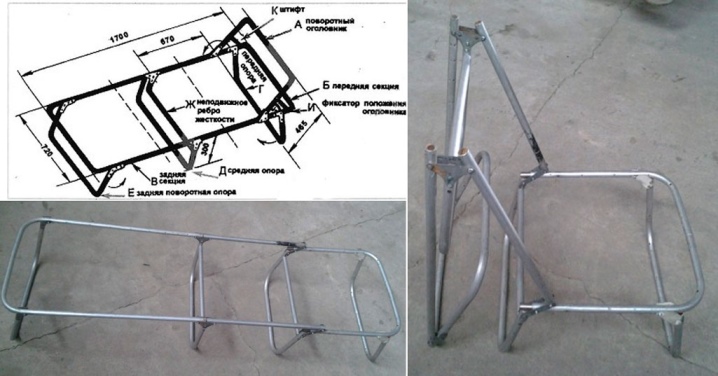

Almost every one of us has an old folding bed in the country or on the balcony. If it is not in use, then it can be used to make a pretty good folding chair. To do this, we first need to cut out the part located in the middle, together with the leg, and then connect the remaining parts to get such a sun lounger.

First, we mark the areas that we will saw off with a hacksaw. After that, we carry out a blank of a metal rod, from which an 8-centimeter-long insert will be made. Having retreated from the place of the proposed cut by 3-4 centimeters, in one of the tubes of the frame we make a through hole for a rivet or an M5 screw. A hole of the same type should be made in the insert.

They should now be connected and secured with the specified screw. Now the tip of the second abutting tube is pushed onto the insert, after which they should be drilled in the assembly. Then the tubes with the insert are fastened with rivets or bolts with Grover washers and nuts. This completes the chair frame.

If the cot has a reclining canvas, then you can leave it and use it. It is only necessary to remove the spring braces in the place where the middle part of the folding bed used to be, fold the released piece of cloth in half and put it on the seat. If the cloth is worn, then it is better to make a new one from some kind of dense fabric. The material can even be removable or made directly around the scaffold tubes.

The advantages of such a chair are pronounced - it has a small mass, the frame is resistant to moisture, and the properties of the clamshell make it convenient for transportation.

Recommendations

If we talk about recommendations, then the first one, which should be said, is that you should not in any case neglect the creation and careful study of the diagrams and drawings of the chair. How high-quality the chair will turn out depends on their correctness. (without any structural defects and flaws).

The second important point that I want to talk about is that you should use only high-quality moisture-resistant varnish and stain for working out and covering the chair. This is done in order to protect the wooden product from the effects of natural factors (water and ultraviolet rays) and to extend its durability.

Another aspect concerns the fact that there should be no burrs or irregularities on the wooden model... And for this, it is necessary to carry out high-quality processing of the wooden elements of the chair using sandpaper.

As you can see, making a folding chair with your own hands, if desired and with drawings, will not be difficult even for a person without experience in this matter.

See below for a master class on making a chair.

The comment was sent successfully.