Hammer paint: features and benefits

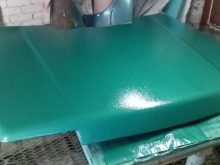

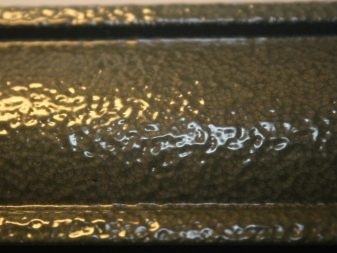

The strange name "hammerhead" appeared because of the specific type of dye. The surface treated with such a composition does not seem to be flat, but mottled with shallow depressions. One gets the impression that she was subjected to shelling, and then they decided to paint it.

However, the authors of the name were, apparently, peaceful people and the texture reminded them of the surface after blows of a blacksmith's hammer. An unusual name stuck to the paint and is still used today.

What it is?

After its appearance, hammer paint was used only in production. Due to its exceptional durability, it has become indispensable for painting equipment operating in harsh conditions. Moisture corroded the beds of machine tools and machines, and blacksmith paint reliably protected the mechanisms from rust and premature failure.

The vast majority of paints and varnishes fit well only on specially prepared surfaces. Preparation consists in cleaning and subsequent priming.

Corroded areas must be thoroughly cleaned. If this is not done, the coating will not last long.

Under the hammer effect paint, it is sufficient to remove loose rust particles. Corrosion damage does not need to be removed.

The dye perfectly "gets along" with metal damage, tightly connects with them, stops the started negative process.

After multi-colored enamels appeared, blacksmith's dye began to appear in areas of human life that were previously inaccessible to him.

First, doors painted by them in private houses appeared on sale. Dull dark colors were replaced by original bright colors with sparkles and tints. The first products were so attractive that they simply did not put others in the new cottages. Since then, the entrance to each new house has been distinguished by its hammer color.

Demand gave birth to supply. The well-proven dye has become widely demanded. This means that a vast field of activity has opened up for designers. And they were not long in coming.

Today hammer paints and enamels are present on forged products, including:

- fences;

- gate;

- metal furniture;

- sculptural compositions;

- decorative dyes.

The beautiful, durable material has found its way into residential and public buildings. Now not only metal is processed with it. Blacksmith paints work well on wood, glass and hard plastics.

But the possibilities of paint are not limitless. Hammer compounds will not adhere to products previously painted with oil, powder or bitumen-containing paints.

It is useless to paint factory products without removing the grease from them. So, new sheet steel or rolled products require cleaning with white spirit or acetone. For better adhesion on the sheets, you need to walk with coarse-grained sandpaper.

Scope of application

The scope of the dye is due to its characteristics. Hammer paint has the ability to resist rust. Therefore, first of all, it is in demand for coating metal products and only then all the others.

In hammer "clothes" they look perfect:

- garage gates, entrance doors, wickets and fences;

- casings of various moving mechanisms;

- cabinets containing electrical equipment;

- building structures, supports, fastenings;

- equipment and laboratory instruments;

- metal parts of park benches, garden furniture;

- safes and safety deposit boxes designed to store valuables;

- forged decorations;

- car parts.

Hammer enamels have transcended traditional limits. Today they are used for the processing of wood, ceramics, hard plastics and glass.

Blacksmith's dye appears in all its glory when applied to a horizontal surface. This means that to paint a door or garage door, they need to be removed from their hinges, given their original horizontal position, and only after that start processing.

The paint, resistant to fading and temperature changes, is often used in the design of outdoor advertising structures. A durable coating is found on high-tech, loft, Provence home furnishings.

Advantages and disadvantages

Hammer paint would not have become as popular as it is now, if it did not have characteristics other than a spectacular look.

The demand for the composition is explained by the following useful qualities:

- Resistant to temperature changes. The paint does not lose its properties and does not crack when heated to + 80 degrees, it is not afraid of the most severe frosts.

- Lack of preliminary surface treatment before applying the dye.

- Possibility of painting directly on rust.

- Mechanical strength.

- Resistant to precipitation, moisture.

- Drying speed. The first place in terms of setting speed is occupied by aerosol paints, they completely harden in a couple of hours after application on the surface of parts.

- The ability to protect metal products from corrosion. The minimum shelf life of the protective layer on external structures is 8 years.

- Lack of negative consequences during operation. No harmful vapors when heated.

- Restoration of consumer properties of corroded objects.

- Wide range of colors.

After the paint dries, the surface of the products acquires the ability to repel dust. The appearance of such products is always neat, they do not need to be constantly wiped clean.

The disadvantages of blacksmith dye include:

- Difficulty of removal. No modern solvent can quickly cope with a tough coating. To remove it, you will have to work hard. In this case, the solvent will only soften the paint; it will have to be removed mechanically using a scraper or an abrasive tool.

- Rust corrosion. It is worth skipping a small section, and the coating runs the risk of being "eaten" by rye. Corrosion will appear on unpainted metal over time. Gradually, it will spread to the dye itself.

- The inability to use a spray gun when working with thick enamel.

- Large paint consumption.

- High price.

Types and composition

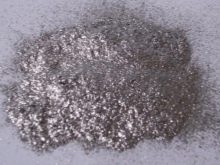

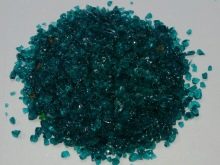

The most significant characteristics are provided to hammer paints by the epoxy and alkyd substances that make up their base. Other components included in the composition are pigments - metal and silicone resins. In a single "commonwealth", these elements give the composition an amazing durability.

The paint is applied very easily and firmly adheres to the surface to be treated. The listed ingredients significantly increase the density of the dye, provide it with a unique ability to resist corrosion.

The additional strength of the paintwork comes from the fillers.

The most important and useful of them are:

- aluminum powder;

- fine fraction glass.

Fillers affect the durability of the applied layer and the increase in adhesion. However, the main merit of these components is that they provide the uniqueness of the texture. It is the fillers that create the effect of hand-chased metal.

The peculiar appearance of the dye makes it possible to hide surface flaws. After staining, chips and shells, deep scratches and small cracks become invisible.

Additives in the form of silicones and aluminum flakes affect the ability to wick away moisture and improve the structure. Technical wax is needed as part of the dye to obtain a protective surface film.

Hammer paints are not available in powder form like some other types. It is impossible to prepare a complex composition at home.

For this reason, ready-to-use liquid mixtures are commercially available. Paints can be sprayed in cans or in traditional containers - metal cans. Large volumes are packed in plastic buckets.

The components included may vary from manufacturer to manufacturer. This is how one or another characteristic is achieved, mainly aesthetic - matte or gloss.

Colors

The first hammer paint was not original. She, of course, was not too boring, like her "brothers". External "roughness" put the dye in a separate row. And yet, the gray color was not pleasing to the eye.

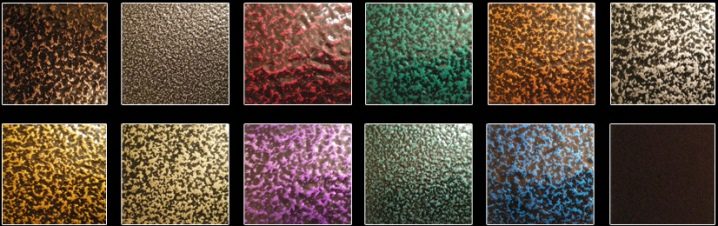

The addition of pigments to the composition made it possible to diversify the colors of enamels and paints. White, black, blue, brown, red and other hammer paints are presented on the shelves of shops of paint and varnish liquids.

Products of the Hammerite brand are distinguished by a special variety.

Smooth semi-matte group of dyes, in addition to the listed colors, includes:

- dark brown;

- lavender;

- Gray;

- dark grey.

Hammerayt paints are also different, including:

- dark blue;

- blue;

- copper;

- light green;

- dark green;

- silvery.

Other manufacturers offer a less extensive palette.

Blacksmith paint can be glossy, matte or have an intermediate texture - semi-matte. The greatest demand is for matte black and glossy white paint. The gray color, as before, is in demand. Various devices, metal parts of furniture for home and offices are treated with discreet dyes.

Brands

The most famous brand of blacksmith dyes is Hammerite... The hammer effect of paintwork materials is obtained due to the inclusion of the smallest particles of tempered glass and aluminum flakes. Regardless of the type, Hammerite varnishes have a high hiding power and adhesion that is unsurpassed in comparison with other manufacturers.

The company produces the following types of dyes:

- smooth enamel with a shiny texture;

- hammer rust enamel - contains aluminum flakes;

- anti-corrosion matt paint;

- semi-matt anticorrosive paint;

- special paint that is not exposed to high temperatures;

- a synthetic resin-based compound designed to protect roofs from corrosion.

For ease of use of paints, the company invented and put on the market a solvent that allows you to reduce the viscosity of the composition. Thanks to this tool, thick enamels can be applied not only with a roller, but also with a spray gun.

LKM Hammerite - available in cans and aerosols. For coloring small items, you can purchase the composition in a jar weighing 0.25 kg. It is more convenient for industrial consumers to buy large quantities in 20 kg buckets. On average, one liter of dye is enough to process 4.5 sq. m of surface.

Hammerite paints are the highest quality and most popular, despite their high cost. They are used for painting car bodies, metal decorative parts of building facades, fences and so on.

Dali Is another well-known brand in the dye industry. Dali paints are intended for protective and decorative coating of the surfaces of metal products.

The composition can be applied to the places of punctual or continuous damage by corrosion, which has penetrated to a depth of no more than 100 microns.

Dali paints are used for the treatment of all metal surfaces, both new and previously painted. They are safe for humans, therefore they are used not only outdoors, but also indoors, including residential ones.

The dye fits well on:

- steel and cast iron parts;

- non-ferrous metal products - zinc, aluminum, copper;

- stainless steel and galvanized;

- wood, provided that its moisture content does not exceed twenty percent.

Dali paint is ready for use at a temperature in the working area of at least + 8 degrees. It can be stored and transported both at positive and negative temperatures. Does not lose properties when frozen. Shelf life in a closed container is 3 years. The coating remains resistant for seven years.

For the application of Dali "3 in 1" enamel, loose rust and oil contamination must be removed.

The composition is at the same time:

- rust converter;

- primer;

- protective and decorative coating.

Enamel is characterized by:

- resistance to weathering and ultraviolet light;

- good covering ability;

- even distribution;

- resistance to oils, weak solutions of acids and alkalis.

The paint is applied in several layers with a brush, roller or by spraying. Each subsequent layer - after a certain time specified in the instructions for use. The three-layer coating acquires its final durability after 7 days.

It is possible to dilute the dye up to 10% by volume. Solvent and xylene act as a diluent.

Judging by the reviews, Dali paints fit well on new and painted surfaces, retain their durability for the stated period, have a glossy shine, and are in demand.

Hammer enamel "Prestige" performs three functions:

- primers;

- coloring;

- decorating.

It is applied on metal surfaces in several layers. It takes 60 minutes for one layer to dry. Full hardening occurs within 24 hours after the application of the last layer. The result is a semi-glossy anti-corrosion coating.

Advantages of the composition:

- rust protection;

- durability and hardness;

- hiding power;

- forging effect;

- beautiful appearance;

- low cost.

The Prestige brand is available in several colors, including:

- golden;

- Brown;

- silver red;

- silver blue;

- silvery green.

Reviews of the composition confirm the durability of the paint if the painted objects are in the room. It is better to treat objects located outdoors with a foreign dye.

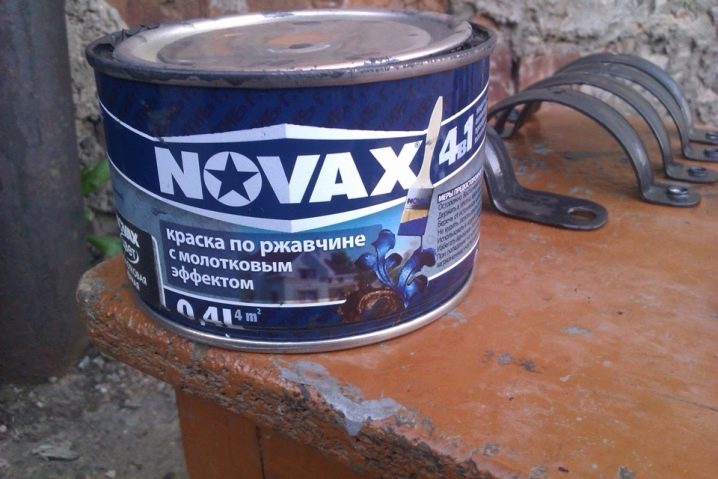

The paint "Novax", according to the annotation, has the same properties as imported counterparts.

Based on user reviews, the dye:

- easy to apply;

- does not require special training;

- has no smell;

- is spent economically;

- diluted with an original solvent;

- can be applied with a spray gun.

The paint does not cause much enthusiasm. On the contrary, there are a number of complaints against the manufacturer. For example, the color instead of the declared black turned out to be graphite. The actual volume does not always correspond to that indicated on the container.

Under these circumstances, only 25% of users left positive product reviews. The remaining 75% of consumers expressed dissatisfaction.

How to choose?

When choosing paint and varnish coatings, the location of the processed products must be taken into account. So, when it comes to gardening tools, benches or garage doors, you can ignore the smell of paint. When working indoors, strongly smelling types of dyes should be excluded.

Outdoor paints must withstand significant temperature changes, be resistant to all types of precipitation, and not fade in bright sunlight.

Colors should be chosen so that new or renewed items fit perfectly into the existing environment.

If a vertical surface is to be painted, preference should be given to quick-drying compounds. Otherwise, drips will occur. However, it is unlikely that such an attractive hammer effect will be created. The heavy particles that provide it will simply slide down.

It is necessary to take into account the method of painting. For example, thick enamel cannot be applied with a spray gun. And when working with a brush, it will take much more time.

The consumption of paint should be taken into account. You need to focus on the instructions.

Manufacturers indicate the consumption of funds per square meter. Difficulties can arise when using aerosols. Without skills, it is quite difficult to distribute the paint evenly.

If you want to get a flawless coating, choose paints that match the type of surface and conditions for further use.

For information on how to properly paint a metal gate with hammer paint, see the next video.

The comment was sent successfully.