Ordinary brick: what is it and what characteristics are different?

Ordinary brick is used today for various types of construction work. It is made from clay and subsequently fired at high temperatures. Ordinary ordinary brick is used for the construction of internal and external walls in buildings for various purposes. The masonry is formed using cement and sand compounds.

Product design features

A solid single brick after laying requires additional finishing or plastering of the base with other materials, since it does not have an ideal surface. The grade and strength are usually indicated on the stone, and stones of the M100 or M150 brand are used for the construction of buildings of 1–2 floors. If the building is more than 3 floors, then ordinary brick laying is not performed.

It is produced in the form of rectangular products and happens:

- hollow;

- corpulent.

These types of products differ in thickness, size, resistance to low temperatures, strength, texture and weight.

The strength of such a product is indicated by the letter M with numerical values, and frost resistance by the letter F with a numerical value.

- Strength. For example, a stone of the M50 brand is usually used for laying partitions, or it is used for low structures that do not have a large load. Brick of the M100 brand can be used for the construction of the main walls. Products of the M175 brand are used for the construction of foundations.

- Water absorption. Water absorption is also considered important, which indicates the ability of the product to absorb moisture. This value is determined as a percentage and indicates the amount of moisture that a brick can absorb in percentage. The tests are usually carried out in a laboratory setting where the brick is placed in water for 48 hours. Standard brick has a water absorption of 15%.

- Frost resistance. It determines the ability of the product to withstand freeze / defrost cycles and this indicator is also affected by the level of water absorption. The less moisture the brick absorbs, the greater its resistance to low temperatures. Under standard construction conditions, it is recommended to use brick grade F25, and for load-bearing foundations - F35.

- Thermal conductivity. This is also an important indicator that can fluctuate depending on the type of brick. For a standard product, the thermal conductivity is 0.45-0.8 W / M. To ensure good thermal insulation of the building when using this type of stone, it is recommended to lay out walls up to one meter thick. But this is rarely resorted to, and therefore an additional layer of thermal insulation is usually used for the base.

And also when choosing, you need to pay attention to the color of the product, which indicates the composition of the clay that was used in its production. All these indicators are determined by GOST, and the product itself must meet the parameters that are approved by the manufacturer.

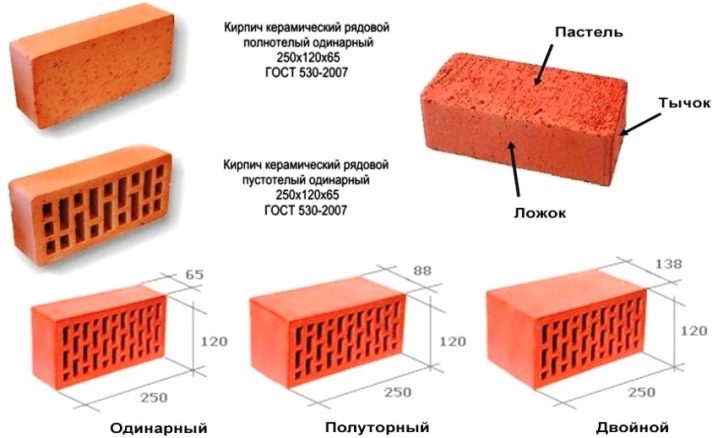

Dimensions (edit)

Stone for ordinary masonry is produced in the following sizes:

- single - 250x120x65mm.

- one and a half - 250x120x88 mm.

- Double - 250x120x140 mm.

Production

The main material from which silicate and other types of bricks are made is clay. It is mined in quarries, after which it is cleaned and crushed. Then it is mixed with water and, if necessary, other components are added.Then the mixture is formed and mixed, after which it is laid out in shapes in accordance with the dimensions of a particular type of stone. Further, the workpiece enters the furnace, where it is processed at a temperature of 1400 degrees. This material turns out to be warm and environmentally friendly. When fired, the color of the brick turns red.

Typically, brick production sites are located close to clay deposits, which allows you to reduce production costs and use homogeneous raw materials.

It is also important to observe the correct addition of the components and their mixing. The amount of clay is determined depending on its mineral composition.

Advantages and disadvantages

Characteristics of ordinary bricks quite high and it is appreciated:

- strength;

- low water absorption;

- incombustibility;

- long service life;

- small cost.

Minuses:

- heavy weight;

- work must be done with experience;

- the masonry process is laborious.

Hollow and solid product

Depending on the needs, this brick can be produced solid, which is made in the form of a solid bar without through holes. This material has good sound insulation and can keep the building warm. It is resistant to water and other aggressive environments. The weight of one brick is 3 kilograms. They use it for the following purposes:

- arrangement of furnaces;

- laying of foundations;

- the construction of load-bearing walls;

- manufacture of partitions.

Hollow brick has holes. They can be square or round. The presence of such cells improves the thermal insulation properties and reduces the weight of the product. But at the same time, the strength of the brick deteriorates. The weight of such a product is 2-2.5 kg.

It is used for such work:

- erection of buildings with a height of no more than 3 floors;

- constructions of various decorative structures;

- erection of structures that will not be affected by a high load.

Views

There are different types of ordinary bricks. All of them are actively used for construction work of any complexity.

Ceramic product

This is a type of building brick. It has standard dimensions, which makes it easy to use in construction. For facades made of this material, it is necessary in the future to trim or insulate the base.

Silicate and clinker

These bricks are subspecies of ceramic, and are produced using a special technology. Refractory clays are used for their manufacture, which are superimposed into molds in layers and mixed with each other. The firing of such a product is carried out at a temperature of 1200 degrees, and the process of exposure to high temperature continues until the layers are sintered, as a result of which an inseparable bar is obtained. The color of the material may vary depending on the type of clay.

The advantage is high thermal conductivity, and the disadvantage is high weight. The disadvantages include the high cost and complexity of manufacturing. Usually this type of brick is used for the device:

- steps;

- columns;

- pillars;

- tracks and stuff.

Silicate brick is used as a facing or ordinary material. It is made from quartz sand, lime and additives. In order for the material to obtain the desired color, pigments are added to it, which improve the characteristics, and also change the color. As a result, it turns out:

- white;

- blue;

- green;

- purple and so on.

These products differ in strength and have good sound insulation, but at the same time they can absorb moisture, moreover, they are unstable to low temperatures.

This type of brick stands out for its attractive appearance, therefore it can often be used in the form of facing. Since this product is made full-bodied, it weighs quite a lot, which excludes the possibility of high-rise construction with its help, therefore it is often used for the construction of low-rise buildings. In addition, the use of this type of brick requires the creation of a strong and solid foundation.

Masonry features

To make the construction of this brick durable and of high quality, you must adhere to these rules:

- do not use bricks with defects;

- initially determine the type of masonry;

- fill the voids between the bricks with mortar;

- use plumb lines and cords to determine the vertical and horizontal masonry;

- ensure the solidity of the structure with the help of reinforcing materials;

- to allow the mortar to set during laying, so that the base does not shift;

- make seams at least one centimeter thick to avoid cracking.

For construction, you can use both silicate and ceramic ordinary bricks, choosing them depending on the type of construction. It is also important to carefully transport and unload / load these products so that they do not get damaged or split.

In the video below, you will learn about the mistakes of novice bricklayers in brickwork.

The comment was sent successfully.