Brick density: standards and advice for determining

If it becomes necessary to buy a brick, then when choosing it, you need to pay attention to certain points, including sizes, types, purpose, quality, and so on. It is also important to choose a brick for the construction of certain buildings, depending on their purpose. In this case, we are talking about load-bearing structures and partitions. In this case, it is important to pay attention to the density of the brick. It is not the same for different types of stones.

What does it mean?

This value determines what performance the structure will have. The strength of the future structure is determined by the density of the building stone. Also, the durability of the structure and its thermal insulation depend on it. The more weight the brick has, the worse it protects the structure from the cold.

Experts distinguish between two types of stone density - average and true.

It is possible to determine the true density by applying various formulas, but the average consumer is not interested in this method. It is important for him to know the average density of bricks from a particular batch, which is determined by the formula p = m / v.

Views

Nowadays, there are many different types of bricks that are used in construction. Each of them has a standard density indicator.

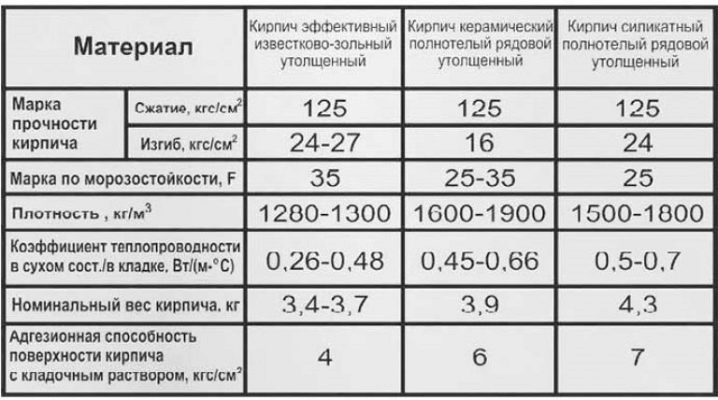

Silicate

The main components from which this brick is made are sand, clean water and slaked lime. This mass is formed by processing in autoclaves under the influence of wet steam. The process is carried out under pressure. Thanks to this, the strength, resistance to low temperatures and sound insulation of the stone are at the highest level. It also rarely has efflorescence on the surface.

The downside can be considered high thermal conductivity, weight, instability to high temperatures and moisture. Silicate bricks can be used for the construction of partitions or walls, as well as other structures where they will not be affected by high temperatures. The possibility of using chimneys, foundations, wells, sewerage and other structures for laying is excluded.

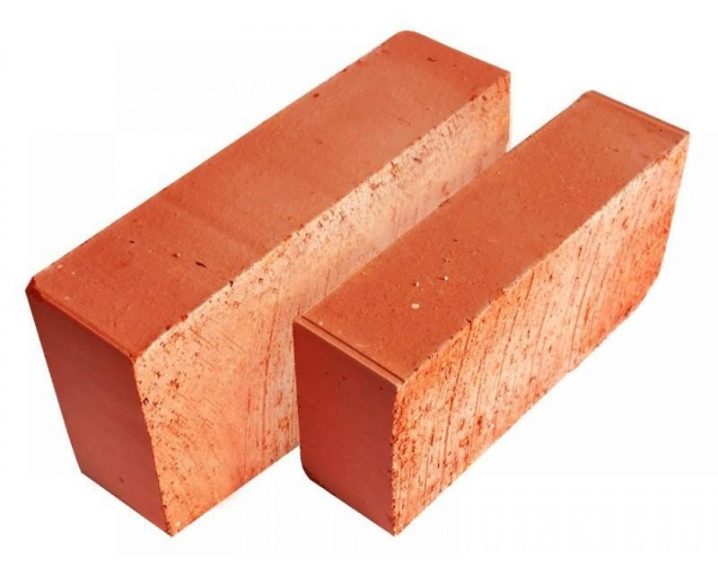

Ceramic

The main component in its production is clay. The manufacturing technology is simple and represents the molding of products from clay raw materials and their subsequent firing at high temperatures. Such stones are distinguished by good sound insulation, high strength, absorb little water, tolerate frost well and have a high density. These are the main advantages of such a building material.

The disadvantages include high cost, high weight and the appearance of efflorescence on masonry when used in wet conditions. This brick is used almost everywhere. It can be used to construct both load-bearing foundations and partitions. It is often used for the construction of foundations or sewers.

Hyperpressed

This brick is based on limestone, which is processed into small fractions. Cement and pigmentation are also added. All this is formed into a mass from which a brick is made under pressure. Such a stone is distinguished by its high density, resistance to different temperatures, beautiful appearance and clear geometry. The disadvantages include increased weight and poor thermal conductivity. Such products are used for the construction of decorative fences and cladding.

Structure

Also, brick is divided into several types, depending on the density and structure.

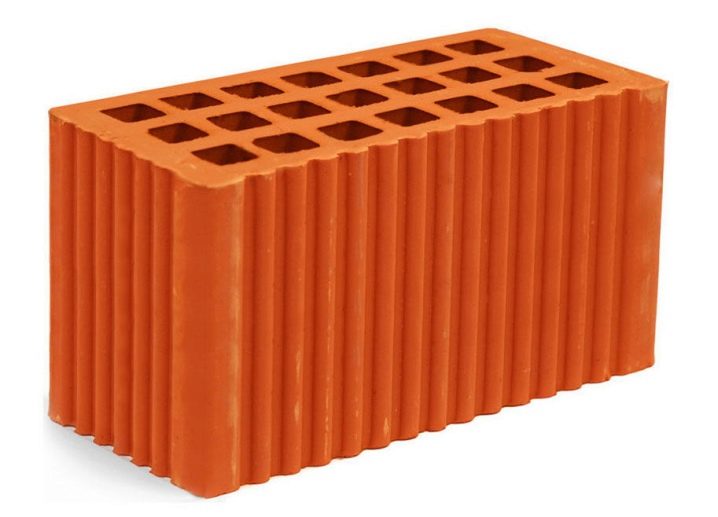

- Hollow. Has voids in the body, which occupy about 50% of its total mass.As a result, the stone is distinguished by improved thermal insulation characteristics, as well as low weight. It is used for partitions, cladding of facades or the construction of load-bearing foundations of buildings, which will not be affected by a large load. The holes are different. The density is 1300-1450 kg / m3.

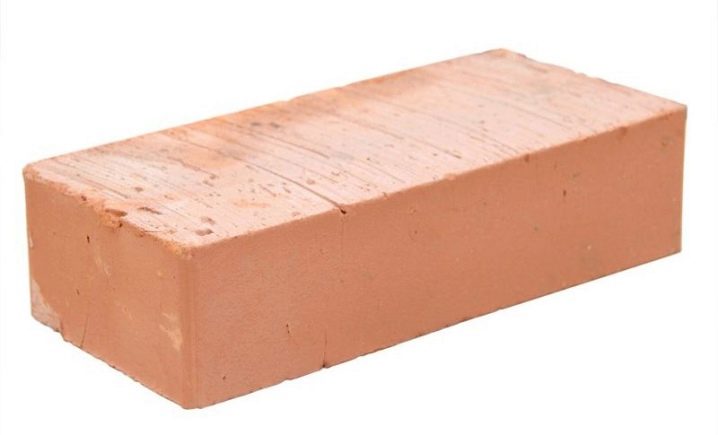

- Corpulent. This brick contains about 13% of the void from its total mass. They use it for supporting structures, columns and more. High thermal conductivity limits the scope of the stone, and therefore it is not always possible to construct the outer walls of buildings from it, which will be characterized by high thermal conductivity. Density - 1900-2100 kg / m3.

- Porized. This type of material has a porous structure, which provides good sound insulation and thermal insulation. Also, this stone weighs a little. It is used in the same areas as hollow bricks. Density - 700-900 kg / m3.

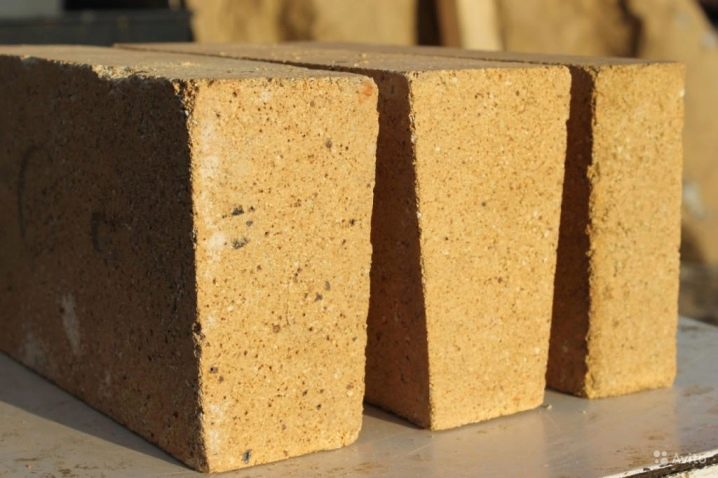

It is possible to note separately the fireclay type, which is used in those places where it will be exposed to high temperatures. Usually such a brick is taken for stoves and similar objects. The stone can withstand temperatures up to 1800 degrees, and its density is 1700-1900 kg / cu. m.

Marking

After production, each batch of building stone is marked with numbers and letters. It is not difficult to decipher such values, for example:

- R - private;

- L - front.

Further, there may be other designations for the size and type of brick, which are deciphered as "Po" (corpulent) and "Pu" (hollow). All these parameters are regulated by GOST 530-2007. Other designations may also be indicated, for example, strength, size, frost resistance and others. The average density of building stone can be from 0.8 to 2.0. Therefore, when making a purchase, it is important to pay attention to these parameters and product class.

The building type, it is also called ordinary, is used for laying walls, on which finishing materials will subsequently be applied. Also, columns, plinths, ventilation ducts and more are erected from it. Ordinary can be both silicate brick and ceramic. The choice of brand in each specific case depends on what parameters must be achieved from the future structure.

Facing brick is taken for facades and its difference is that it has two flat surfaces that are distinguished by a beautiful appearance. The facing material can also be hollow or solid. Some types of bricks for facing structures may have additional decorative elements, as well as glazed or otherwise processed surfaces.

Shipping

The possibility and method of transportation also depends on the type of brick. Ceramic products can be transported by any type of transport on pallets. Such packages are formed directly after brick production. On pallets there is a certain number of stones of the same batch, which do not differ in their color and other characteristics.

For the construction of structures, it is recommended to choose bricks from the same batch, which will not differ in parameters and other indicators. It is necessary to store such a brick in sheltered shelves. Stacks should be no more than 4 tiers high.

If we are talking about a solid material, which has a high density, then the same requirements are imposed on it during transportation and storage, but at the same time this brick can withstand heavy loads and is not damaged during transportation.

When buying a building stone, it is recommended to pay attention to all these points, and it is also worth giving preference to trusted manufacturers who indicate the exact parameters of the batch of their products in the documents. Although this requirement is regulated by law, and for the provision of inaccurate information, the manufacturer may be liable if, due to incorrectly applied marking, damage to the developer is caused in the future.

From the video you can learn about the density of ceramic solid bricks.

The comment was sent successfully.