Pros and cons of ceramic blocks

Unlike a foam block, a ceramic block has a specific structure. Its real, solid part, does not consist of porous, but of dense building material that does not have microscopic voids, with the exception of possible microcracks formed during its long storage.

Main advantages

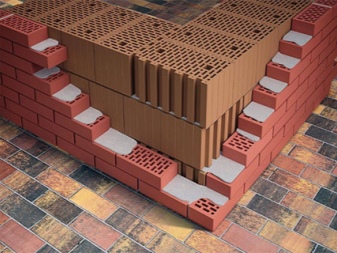

Due to the groove-and-tenon joint vertically, the ceramic blocks are connected tightly. Bonding cement-sand mortar - as well as cement glue - are not needed. All that is needed is to fit the blocks tightly together. The rectangular and square pores that penetrate each ceramic block run parallel to each other and are completely closed.

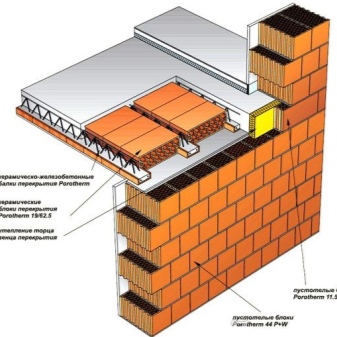

The lattice structure of the ceramic block is needed so that these blocks do not conduct heat as quickly as their solid, corpulent counterparts. This allows you to keep the coolness inside the house longer in summer, and in winter - to prevent heat from quickly leaving the inner space of the rooms. Thus, the air inside the ceramic building material provides additional thermal insulation.

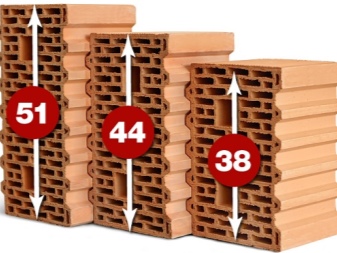

The ceramic block can withstand twice as much pressure as a brick. This means that the load from the upper rows of walls to the lowest one, together with the roof, can be doubled. The load of the ceiling-attic floor and the roof on the walls is also allowed twice as much. For example, instead of roofing steel (profiled sheet), you can put slate on the roof, which is characterized by a large weight, while the walls do not deform at all, cracks will not appear - as would happen with a foam block or a frame-timber frame of a building.

If we translate the pressure on the ceramic block into physical quantities, then for a brick this indicator is 5 megapascals, and for a ceramic stone - all 10 MPa.

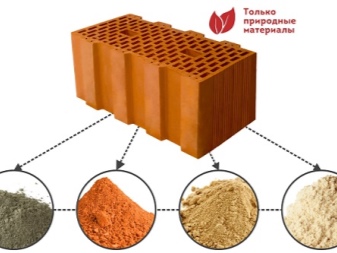

Clay, fired, baked according to modern technologies, will not dry out in the heat, will not crack from frost after rain - which ultimately determines its advantages as a building material. Ceramics are much stronger than ordinary "brick" clay.

Clay, fired, sintered using modern technologies, will not dry out in the heat, will not crack from frost after rain - which ultimately determines its advantages as a building material. Ceramics are much stronger than ordinary "brick" clay.

Its advantage is that it is able to heat up to a crimson heat glow without losing strength. To believe this, all you need to do is toss a bad car spark plug into the fire - it's made of steel and ceramic. The hardness of ceramics is much higher than even some metals. This explains the high value of the maximum allowable pressure.

Clay sintered by "ceramic" technology is not afraid of aggressive environments. Even perchloric acid - the strongest in action - will not immediately act on it. Ceramics is not a dusty environment - unlike ordinary bricks, concrete, gas silicate blocks. It is comparable to granite, but it is also capable of "dusting" a little.

Houses built from ceramic blocks are as safe as possible in this regard. You don't have to worry about breathing in dust from minerals, clogging up your lungs and eventually leading you to respiratory diseases. Not to mention such products as asbestos pipes and slate, which, when processed, emit light and very volatile dust.

The ceramic block is harmless in terms of the composition of its structure. There are no chemically active and harmful additives in it.Unlike silicate bricks and gas silicate blocks, in which slag materials are used as secondary waste, as well as some additives that protect, for example, from mold, fungus, microbes, insects, rodents, a ceramic block does not need all these reagents.

Besides, it has been proven that clay sintered according to all the rules is significantly superior in strength and resistance to decomposition and spillage of all these artificial materials. Even in a burnt state, it does not lose its ecological purity and harmlessness to humans - while the same foam and gas silicate bricks every year cause more and more doubts about their quality.

Many self-builders who understand construction are sometimes no worse than custom-made professional craftsmen, are sure: gas silicate is forged, violating the manufacturing technology, which, by the way, was originally designed for a 50-100-year service life of houses built of aerated concrete. This is done in order to obtain super-profits, many sellers are not interested in the highest quality products.

There is no point in faking clay products: clay is ubiquitous, it can be dug up in any clay-bearing quarry and even near the house, for example, when digging a foundation pit for the basement. Burning it and getting a simple underfired brick, passing it off as ceramics, also makes no sense. Ceramics does not require any additives or additives during production - only carefully dried clay is used, burned according to the standard and technology. Energy and resource costs are limited only by the firing process itself.

The noise insulation of ceramic blocks is the same as that of simple clay bricks - this is enough for most cases.

Overview of obvious deficiencies

Ceramic blocks also have disadvantages. Like any slotted block, the ceramic block is characterized by reduced strength due to its cellular structure. In this way, it resembles a hollow brick - even clay, even silicate - in which they made round, square or rectangular cells. The box-shaped structure is noticeably inferior to the solid one in terms of safety margin. In other words, a ceramic block can be compared to the same brick, in which the holes (or cells) are smaller - due to the thicker inner walls.

If you drop a ceramic block, it breaks easily, like any cellular brick; it requires careful handling during transport and storage. Therefore, it is transported in packed stacks - shaking, block displacement is almost completely excluded, transportation resembles the delivery of aerated concrete products or cellular facing bricks. The ends are especially sensitive to impacts. Workers overloading such blocks are forced to be extremely careful.

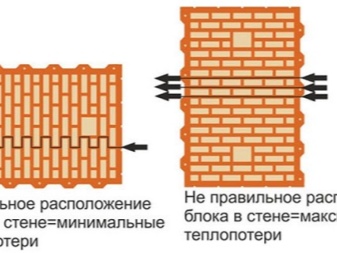

No less attention is paid to finding specialists who work with such units very carefully. Brick fight is not allowed here, and violation of the technology of laying blocks into walls threatens the fragility of the constructed building. If you violate the block stacking scheme during construction, then the so-called cold bridges, gaps, due to which the heat saving in the room will sharply decrease, are formed. If, when laying a brick wall, some irregularities are allowed - they are compensated by cement-masonry joints - then vertical joints when laying blocks must be carefully adjusted so that gaps, including oblique ones, do not arise.

Walls made of ceramic blocks do not tolerate hammering nails, drilling holes for screws and dowels. Even if you need to insert a plastic dowel under the self-tapping screw, ceramic should be drilled with the greatest care - just like drilling a tile. The downside here is that rock drills and hand breakers cut the material into pieces. If you need to hang a cabinet on such a wall or support a console, then special fasteners for hollow ceramics are used.

Cutting grooves for signal and power electrical cables, corrugations for them is done using chasers with the fineness of the sawing and grinding process.

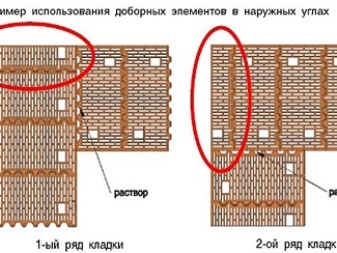

To divide the ceramic block, you need a saw - disk or saber-frictional. Not every disc can cut a ceramic block in two - in corners and transitions, where the walls allow joining the masonry "in the paw" in order, the blocks are sawn with a diamond disc (which is used for sawing, for example, porcelain stoneware) or with a reciprocating saw. Remember that one wrong move - and the block gets a large chip or cracks into several parts.

The calculation of the safety factor of the structure is carried out with the help of an architect. It is strongly recommended, if you have not learned how to lay these blocks perfectly smoothly and safely, to involve professional bricklayers who have built more than one hundred such structures.

conclusions

- For the construction of a bath or a house, ceramic blocks are as safe as possible - with strict observance of the installation rules.

- The ceramics does not burn. Even in the event of a fire, the house with a high degree of probability will "survive", although all combustible materials and structures will burn out.

- The building made of ceramic blocks is warm in winter and cool in summer. The ceramic block is almost irreplaceable where humidity and temperature change significantly. Changing the heat with torrential rains, winds and cold snaps will not affect your home - in terms of strength and reliability - for a number of years.

- Large-format blocks allow you to build a structure in a few tens of hours - or in a few days, from the moment the foundation is suitable for further construction work.

The comment was sent successfully.