Iron fireplace: device features and manufacturing

Almost every owner of a private country house dreams of a fireplace. Real fire can create a pleasant and cozy atmosphere in any home. Today, a wide range of fireplaces is presented on the construction market, including luxuriously decorated expensive models, and quite affordable options. You can make an iron fireplace yourself.

Peculiarities

Today, fireplaces made of iron are very popular. It should be noted that such structures cannot be installed in small rooms. Such a structure needs a constant flow of air, and in a small room this will be difficult to achieve. Therefore, before buying, be sure to evaluate the size of your home.

The installation of an iron fireplace must be started by laying a special stand. Such a support can be either purchased at a hardware store, or made yourself from metal corners. To make a structure at home, you need to cut the corners, and put a sheet made of the same material on top.

It is also worth paying special attention to fire insulation. All chimney passages that go through the ceilings must be carefully insulated. It is best to treat the wall to which the fireplace will be attached. Such work is necessary to ensure safety in the house and eliminate the risk of a possible fire.

It is important to remember that the firebox for such a fireplace is always made of sheet metal. At the same time, it must be divided into two parts (smoke compartment and wood combustion compartment). Between these sections, there must be a damper that accumulates heat. You can also easily make such a partition with your own hands.

Advantages and disadvantages

Iron fireplaces have a number of important advantages:

- easy installation;

- the speed of heat spreading throughout the room;

- high level of efficiency;

- low weight of the structure;

- ease of maintenance.

Despite the considerable list of positive qualities, iron fireplaces also have certain disadvantages:

- risk of getting burned from the stove;

- cooling speed

- uneven heat distribution.

Mounting

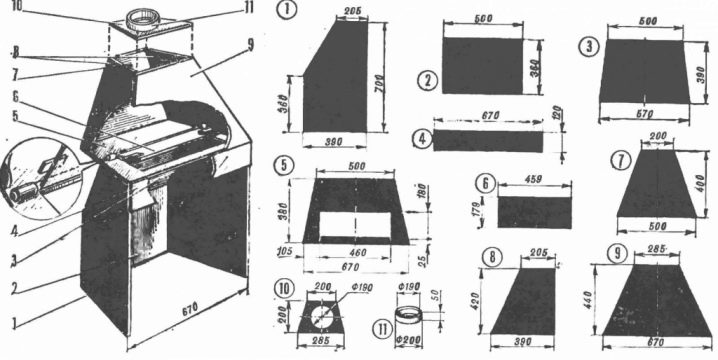

Before proceeding with the installation work, you need to create a drawing of the future product. When drawing up a diagram, it is necessary to take into account not only the structure itself and its individual parts, but also the exact dimensions of the object. It is also important to define a clear assembly order, which should also be reflected on paper.

Prepare the floor covering before starting the installation. To do this, it is covered with special basalt wool, which serves for thermal insulation of the base. Otherwise, the floor will heat up quickly enough, which will lead to its further destruction. Some builders recommend doing this when preparing the wall.

After carrying out the preparatory measures, you can start assembling the future iron fireplace. First, it is recommended to connect the side parts of the structure by welding. The front and back parts are attached to the resulting structure. In this case, we must not forget that a special hole needs to be made in the front part. It is necessary for placing firewood inside the structure.

A metal sheet is also attached to the resulting structure by welding. It will be the bottom of the iron fireplace. Before installing the base, you need to attach the legs to it. Their standard length is 10-12 cm.The number and width of the support pieces depends on the weight of the main item.

At the end, as a rule, a special damper is installed. It serves as a partition between the compartment in which the wood is burned and the compartment in which the ash accumulates. Quite often, such products are made from several layers. They are also made from different metals.

Care

Each owner of an iron fireplace should regularly thoroughly clean the structure from soot and other debris. Otherwise, smoke and various harmful substances will enter the room. It should also be noted that wet cleaning of such devices should not be done. This procedure can lead to severe corrosion.

Most experts recommend that chimneys be cleaned regularly. This cleaning should be done at least once a month. However, if you use the fireplace all the time, then this procedure should be carried out much more often. Remember to clean the pipes from the top.

Special attention should be paid to cleaning the firebox. It must be regularly freed from coals and ash. As a rule, cleaning this part of the fireplace is done with a scoop and a broom. You can also use a vacuum cleaner for a similar procedure. Some owners of iron fireplaces use soda or dishwashing detergents to clean the structures, which will do an excellent job with the task.

Fuel

Many consumers are at a loss to decide which type of fuel is best for an iron fireplace. Most builders agree that dried larch is the best option for heating such structures. In this case, coniferous woods should not be used. They contain a fairly large amount of moisture, so they do not burn well.

Often, wood shavings, cardboard, paper and sawdust are used to fire iron fireplaces. They are also suitable options for similar designs. But it should be noted that it is better not to use such bases as construction waste and other debris when burning. When they are burned, a considerable amount of substances harmful to human health is released.

Any kind of wood must be processed before the firebox. First, the material is split into separate logs. The thickness of each element should be at least 20 cm. After that, the wood is laid to dry. This is necessary in order for the products to burn better.

Today in many hardware stores you can find wooden parts coated with special resins and substances. Such products do not need to be processed, they can be used immediately. Special solutions themselves promote drying and better combustion of the material.

For the benefits of choosing metal fireplace stoves, see the following video.

The comment was sent successfully.