Concrete fireplace: types and manufacturing features

Who among us does not dream of spending evenings in a rainy autumn like Sherlock Holmes, sitting in a rocking chair, when it is already cold outside, and there is still a whole month before the central heating turns on.

Now residents of an ordinary apartment also have such an opportunity - a concrete fireplace. This type is suitable for both a private house and an open veranda. The advantage of the model is that it has high heat dissipation.

Unlike natural stone, concrete is cheaper and easier to use, easily tolerates temperature extremes and changes in humidity.

Views

You can assemble a concrete fireplace both from factory parts and come up with your own unique design. Models from rings have become widespread. They are easy to install and can be used for cooking both over an open fire and in a cauldron. This type of hearth is perfect for placing on a personal plot.

Decorating with a stone will give the structure a neat appearance, which will organically fit into the exposition of the garden plot. The area around the fireplace, laid with tiles in the same color scheme with the stone, will look very nice.

By the type of blocks, fireplaces can be conventionally distinguished:

- from ready-made concrete blocks - can be in the form of rings or molded parts;

- from ordinary concrete blocks that require improvement;

- from molded aerated blocks;

- cast concrete.

By location:

- wall-mounted;

- built-in;

- island;

- corner.

By type of foundation:

- on a brick foundation;

- on a rubble foundation;

- on a cast concrete foundation.

By the way of registration:

- country style;

- in the art nouveau style;

- in a classic style;

- in the loft style and others.

Installation and assembly

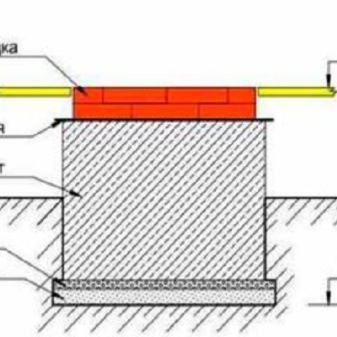

Such models, as a rule, have a foundation at the base. Experts advise you to think about placing a fireplace before building a house. If you install it indoors, for less deformation of the structure and increase the service life, make sure that there is no common bond with the floor.

Otherwise, you will have to dismantle part of the floor covering over time.

Installation work includes the following steps:

- Prepare a pit 0.5 m deep a little more than the outer diameter of the fireplace.

- We lay out the bottom first with crushed stone, then with sand.

- Fill in the resulting DSP cushion, consisting of one part of cement and four sand.

- To prevent condensation from entering, waterproofing material is laid between the upper rows.

- The foundation must protrude from the floor.

- Leave the resulting base plate for a couple of days until the concrete hardens.

Next, you should think about the placement of the chimney. It is best to place it inside a wall if your home is under construction. In the completed room, the chimney will need to be made as a separate structure.

To cut the smoke hole correctly, first mark and cut it out on the concrete ring. The ring should be attached to the chimney without applying DSP.

It is more convenient to make a hole with a special saw with a diamond disc, which can be rented; a grinder will not work in this case. Stock up on special glasses, headphones, a construction vacuum cleaner, workwear and get to work.

Now it's time to start building the fireplace itself.

The first two rows can be connected with DSP with the addition of lime. They will serve to collect ash and will not get very hot. Then use crushed clay mixed with sand.The resulting mixture should have an elastic consistency. When applying, you should check the level of evenness of the masonry from time to time.

In an apartment or room, it is better to build a fireplace from ready-made concrete blocks. They are assembled in the same way as brick:

You will need the following materials:

- Blocks for the back wall 100 mm thick.

- Side blocks 215 mm thick.

- Concrete slab 410x900 mm with an opening of 200 mm, which will serve as a ceiling for the smoke box.

- Portal for framing the firebox.

- A lining that acts as a base.

- Steel sheets and refractory bricks for the design of the pre-furnace site, for fire safety purposes.

- Mantelpiece.

Fireplace device:

- "Under" - the place where the wood burns. It is laid out of refractory bricks on the pavement above the floor level to ensure uninterrupted traction. An additional grille can be installed on it.

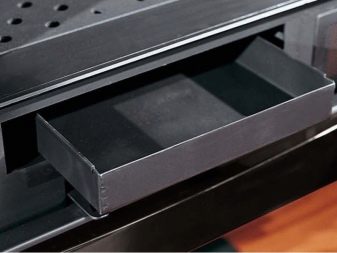

- An ash pan is installed between the base and the hearth. It is better to make it removable in the form of a metal box with a handle.

- Portal grate that prevents firewood and coals from falling out of the fuel chamber.

- Laying out the fuel chamber with refractory fireclay bricks will save on lining.

- Laying out the rear wall of the firebox with an inclination of 12 degrees and finishing it with a cast-iron stove or a sheet of steel will allow to perpetuate the heat-reflecting effect.

- The mantel will give the structure a sense of completeness and a beautiful appearance. It can be made from concrete, marble and granite.

- Installing a pyramid-shaped smoke collector above the fuel chamber will prevent cold air from outside from entering the fireplace.

- The stove damper, installed at a height of 200 cm, helps to regulate the draft force and prevents heat from being blown out through the chimney.

- The chimney should not be lower than 500 cm. To ensure full traction, it is brought out to a height of 2 m above the roof ridge.

- During construction, it is imperative to observe the proportions of the fireplace relative to the heated room.

Construction of a fireplace made of concrete in a finished room

- Preparation consists in dismantling a part of the floor and digging a foundation pit to a depth of at least 500 mm. In a two-storey house - from 700 to 1000 mm. To mark the boundaries of the foundation, take the dimensions of the fireplace table and retreat 220 mm on each side.

- When arranging a fireplace on the second floor, I-beams are used, which are mounted in the main walls to a width of 1.5 bricks. For light models, it is enough to strengthen the logs.

- Construction of the foundation. As a material for masonry, rubble or red brick is used. Its height should not be higher than the floor and it is imperative to have waterproofing to prevent moisture from entering the subfloor. When constructing a foundation made of rubble, the upper two rows are laid out with bricks. For the construction of a concrete foundation, a special solution is prepared with the addition of a sand and gravel mixture, which should be four times more than Portland cement. This solution should be reinforced with a reinforcing mesh. It can be bought ready-made or welded from metal bars with a cross section of 8 mm, soldering them together at a distance of 100 or 150 mm.

- After hardening, we begin to build a fireplace table made of concrete or special refractory bricks, to which the pre-furnace site is adjacent.

- We lay out the side walls of the fireplace.

- We are building a fireplace chamber. To connect the finished blocks, a mixture of one part of sand and cement and six parts of sand is used.

- We install a stove with a hole for a smoke collector. The latter is attached with a 1.5 cm thick mortar.

- Mantel. As a finish, it is worth abandoning ceramic tiles, as they may not withstand high temperatures. Usually brick or stone is used in such cases. Place it in the same way as when building a house - with an offset of half a brick.

The sequence of assembling a fireplace from ready-made gas blocks

- We are building the foundation.

- We moisten the finished blocks.

- We fix the chimney at the height indicated in the instructions, leaving the outlet open.On the DSP we attach sheets of mineral wool along the entire length of the chimney.

- We install the blocks on top of each other without adding DSP and mark with a construction pencil the size and location of the smoke hole. We cut it out using a grinder with a diamond disc.

- We install the blocks on the fireplace table made of iron sheet, fastening them with a mixture of clay and sand.

- Insert the finished podzolnik.

- We lay out the fireplace chamber.

- We fix the plate.

- We make the cladding with bricks.

See the next video for more on this.

The comment was sent successfully.