All about spark arresters

The indisputable fact is that every heating system operating on the basis of the combustion of one or another fuel and requiring the removal of combustion products is a source of sparks. The latter, escaping along with the smoke, pose a potential hazard, primarily to the roofing material. In addition, it should be borne in mind that sparks can provoke fires in areas. This is why it is advisable to learn all about spark arresters that help minimize the associated risks.

What it is?

Any spark arrester is a device that is mounted on the top of the chimney (brick pipe and other elements). It is designed to trap sparks that are often emitted with smoke. It is important to take into account that they also perform an important additional function: they prevent large debris from entering the chimney channel.

Naturally, these designs must meet certain requirements, and we are talking about the following two most important points.

- The spark arrester should provide maximum protection against glowing and unburned fuel particles.

- The device should not in any way affect the traction in the system.

Initially, it should be noted that the presence and design features of the spark arrester are taken into account at the design stage of the chimney system. It is important to take into account that the installation of such devices is recommended for both wooden and brick buildings, as well as buildings made of other materials.

It should be remembered that flying sparks pose a serious danger to the house itself and the site. This is most important when using low-quality fuel.

Another key point is that the fire services strongly recommend installing spark arresters on smoke systems for baths and saunas in which there are intense and hot air currents.

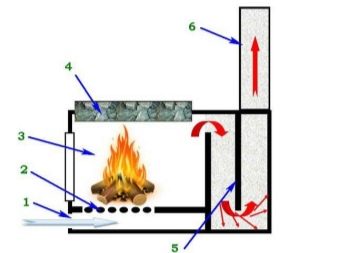

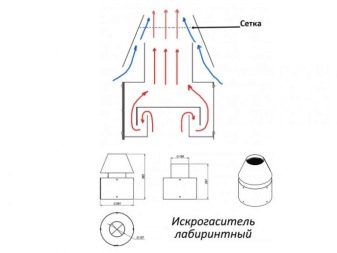

The device and the principle of operation of such protective devices are quite simple. Taking into account the model, they have structural and external features. However, in the overwhelming majority of cases, the following 4 elements are the basis:

- a body made of metal;

- a spark trap that also extinguishes unburned particles;

- flame arrester;

- a visor installed at the very top.

Spark extinguishers, including those for indoor grills and fireplaces, perform their functions on the basis of the laws of heat transfer. Regardless of the design, the considered devices operate according to the following principle.

- Partially unburned fuel elements that rise in tandem with smoke are extinguished due to contact with the walls of the stove or any other chimney.

- The lower segment of the spark arrester is a continuation of the chimney, which extinguishes some more sparks.

- A metal grill or mesh on top provides a barrier to remaining potentially hazardous particles.

If you choose and install the device correctly, then the smoke will pass through it freely, therefore, the draft in the system will not be disturbed. The diameter of the holes plays a special role here. Experts determine the optimal value for containing sparks with a parallel unobstructed passage of smoke 5 mm.

By the way, there are device modifications that not only preserve, but also effectively increase traction.

One of the key characteristics of any type of spark arrester is its service life. It directly depends on the type and quality of the material from which the device is made. As practice shows, a spark arrester with a deflector function, made of ferrous metal, with intensive work as an element of an individual heating system, can last up to 7 years. If we are talking about alloy steel, then the time period under consideration is significantly expanding and is already 10-20 years. Operating conditions will be an equally important factor in this situation.

In accordance with current regulations, the described devices must be installed without fail in the following cases.

- In the presence of flammable materials used in the construction of roof structures and finishing work.

- If the temperature in the premises often rises (baths, saunas).

- When operating various devices running on solid fuels (stoves and boilers in houses and boiler rooms).

The efficiency of all modifications of spark arresters directly depends on a number of factors. In addition to the diameter of the holes in the meshes and grates, it is important to pay attention to the location and height of the chimneys.

Views

The devices under consideration are divided into categories, depending on how they are arranged and functioning. Simple models can be made literally at home, and more complex versions of spark arresters are better to be purchased ready-made. At the moment, there are three main types:

- casings;

- deflectors;

- liquid.

Regardless of the design and principle of operation, all spark arresters should not adversely affect the thrust in the system. It is important that all combustion products of the fuel used pass freely throughout the entire chimney. In parallel, the device is responsible for effective protection against sparks entering the pipes.

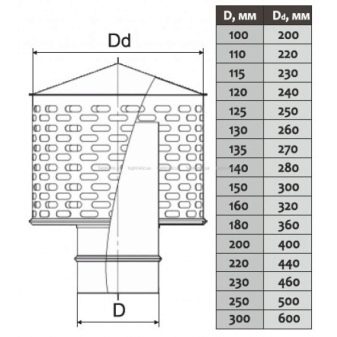

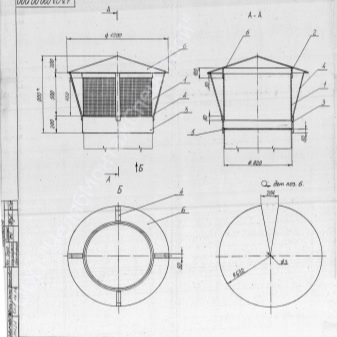

Taking into account the dimensions of the chimneys, the dimensions of the described protective structures also vary. As a rule, this parameter changes in the range of 80-550 mm. The diameter of the top covers (canopies) is determined by the diameter of the connecting pipes. By the way, there are special tables that display this dependence.

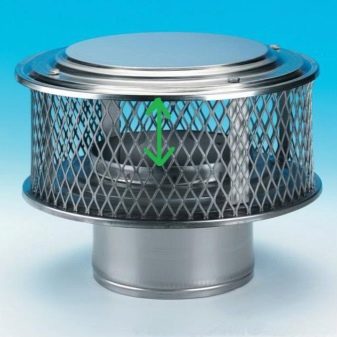

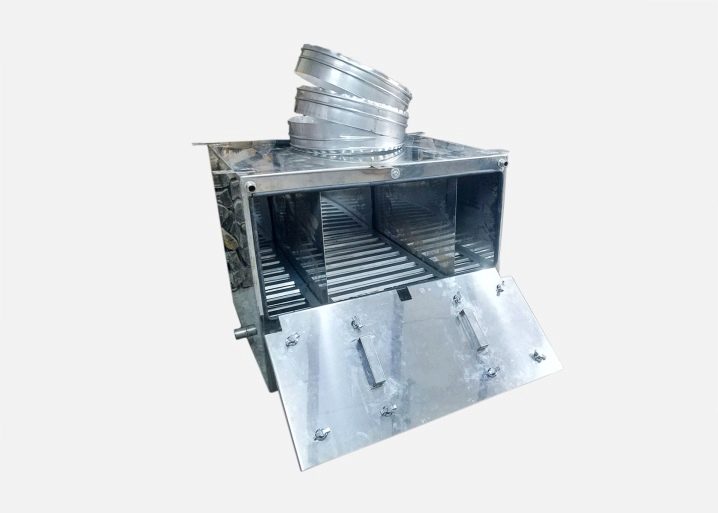

Housings

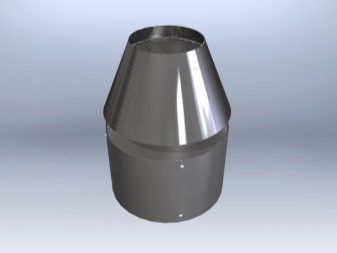

This type of the described devices is the simplest, and therefore such spark arresters can be made independently with minimal financial and time costs. You can understand the design features based on the category name. As a rule, stainless steel is used as a material. It will not be difficult to make an elementary chimney plug with drilled holes.

The key point is in such a parameter as the optimal diameter of these holes. It is important that unburned particles do not penetrate from the chimney to the outside, but at the same time the draft does not deteriorate. When selecting a casing and installing it, it should be taken into account that the dimensions of the device should be slightly larger than the dimensions of the pipe.

It is essential that the spark arrester can be easily removed and replaced if necessary. An alternative to the plug is a roll-up mesh or a perforated tube equipped with a protective cover on top, which can also look like a dome.

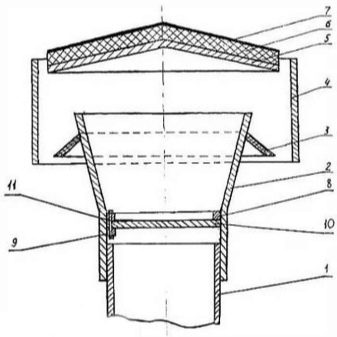

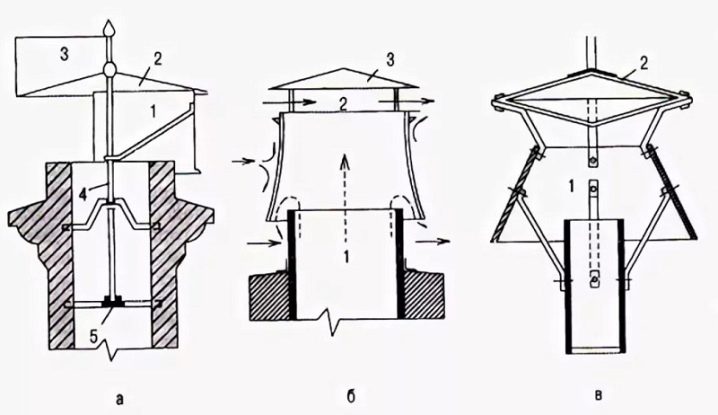

Deflectors

Compared to the previous version, this type of spark arrester is more complex in design. The principle of operation of the deflectors is based on the action of the force of the air flow, which increases the draft in the chimney. It should be noted that there are various types of such aerodynamic devices in which they are used:

- narrowing of the section of the body in certain of its segments;

- annular holes in the body of the spark arrestor;

- mini-turbines;

- sets of rotating visors.

The result is a directional flow that increases thrust. If the deflector is equipped with a mesh or perforated element, it will be possible to create an effective barrier for unburned fuel particles.

It is important to take into account that deflectors are much more aesthetically pleasing than casings and, in addition to performing their main functions, can be an element of roof decoration.

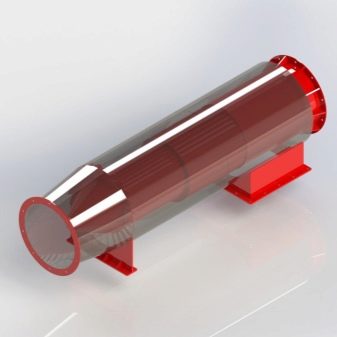

Hydrofilters

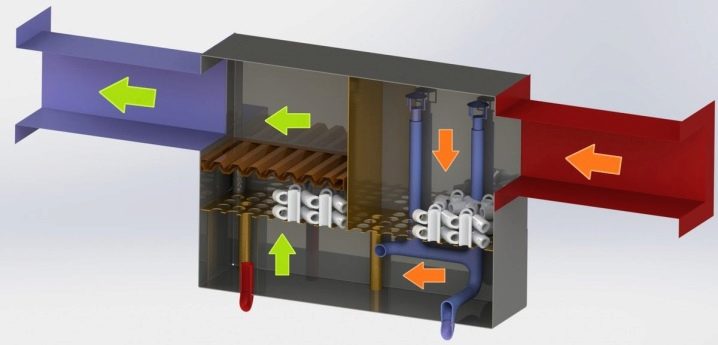

Unlike dry options, this variety is most often used for equipping barbecues and protects chimneys from fires. The water spark arrester has a rather complex design, which includes the following elements:

- smoke hood;

- frame;

- ventilation system;

- mesh made of metal;

- filter elements for fat;

- spray for water;

- water valve;

- pressure sensor;

- separator for water and smoke;

- unit for draining dirty water.

Such systems are installed on round and square chimneys.

A prerequisite is to connect the device to the electrical network, as well as to the water supply and sewerage system for draining the used water. Hydraulic modifications are guaranteed to get rid of sparks, and at the same time also from soot.

Selection Tips

In this case, it is recommended to initially focus on the dimensions of the chimney, the design features of the system, as well as the material of manufacture of its elements. It is important to take into account that the diameter of the described devices varies in the range from 80 to 550 mm.

Another important point is the dimensions of the canopies, which are also determined by the corresponding dimensions of the pipeline.

Also, when choosing a specific model of a device, it is worth considering its variety. This refers to housing designs and options with deflectors. If we are talking about the second type, then the list of the most popular includes the following modifications:

- disc-shaped;

- weather vane;

- H-shaped;

- rotating;

- Grigorovich's designs;

- TsAGI.

Analyzing the materials from which spark arresters are made, it is worth noting that very often the choice is made in favor of stainless steel. It is no secret that in this case we are talking about such key competitive advantages as the absence of corrosion, long service life, aesthetics and relatively affordable cost.

Application

Initially, it should be noted that in the current PPR, which is an official document, the fire regime is regulated. And, in particular, we are talking about the places and organization of the installation of spark arresters, as well as the most critical situations in terms of fire risks. If we are talking about enterprises, including motor transport and agricultural enterprises, then their managers are responsible for the availability and good condition of the described devices. A similar situation is developing in settlements with a predominance of stove heating of houses and outbuildings.

In addition, the owners of private households, as well as summer cottages, saunas and baths must take care of the safety of the operation of such equipment as:

- ovens;

- fireplaces;

- heating boilers;

- barbecues (first of all, we are talking about installations located in the premises);

- other types of devices operating on solid fuel and emitting hot products of its combustion.

In this case, we mean the most effective provision of fire safety. This will be most relevant if there are structures made of combustible and flammable materials on the sites, regardless of their purpose. It is important to take into account the presence of similar buildings and neighbors.

It should be noted that the installation of the considered protective devices that effectively prevent possible fires is relevant both for buildings under construction and during the operation of previously erected structures.

The key point here is the affordable cost of the devices themselves, as well as their maintenance. In the overwhelming majority of cases, after installing a spark arrestor on a chimney, the user has to face the need to periodically clean the nets and gratings from the inevitable accumulation of soot and ash. In practice, such operations do not require significant time and effort.

The installation of such devices on houses, baths, saunas, as well as barbecues and barbecues can be confidently called a vivid example of how a technically simple device can provide maximum protection. As a result, the operation of various equipment becomes comfortable and, most importantly, safe.

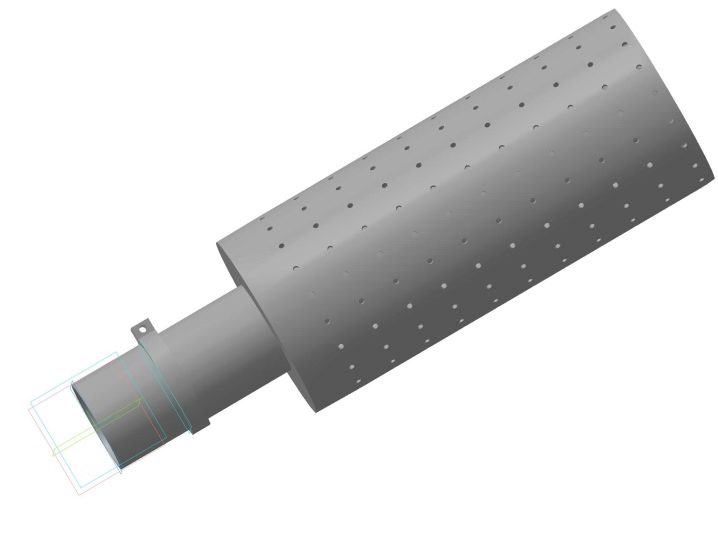

How to do it yourself?

Given the simplicity of the structure and functioning of the described elements of chimney systems, it is possible to make a homemade spark arrester without much cost and effort. It is now easy to find relevant drawings and instructions on the web. The simplest option for a spark arrestor, which is easy to make at home, will be a kind of plug (nozzle) for a chimney with holes drilled in it.

When creating such a plug, it is important to focus on the compliance of its diameter with the dimensions of the chimney. It is important that this homemade protective device can be easily slipped over the pipe. In practice, the manufacture of such a simple element for a chimney system requires minimal skills and free time, as well as insignificant financial costs. At the same time, it is highly recommended to pay attention to the size and number of holes in the nozzle.

A miscalculation can quickly clog the spark arrestor and reduce thrust. Another significant disadvantage of using such a cylindrical device is that it quickly becomes covered with soot during active operation. This, in turn, will cause an unpleasant odor.

The second option is an ordinary metal mesh, which is fixed to the chimney with a clamp. There are two key drawbacks to consider here:

- such devices are not effective enough;

- the nets in such situations, as a rule, become clogged with soot very quickly, which leads to a deterioration in traction.

Another method of manufacturing a spark arrestor is to install a mesh dome on the chimney. It is this option that is considered the most effective among the alternatives to a full-fledged design.

Taking into account the selected type of device for its manufacture, you may need the following:

- ruler and tape measure;

- pliers and clamps;

- hammer and mallet;

- scissors and a hacksaw for metal;

- angle grinder (grinder);

- rivet gun;

- welding machine;

- drill and / or screwdriver;

- screwdriver.

When choosing materials, it is strongly recommended to give preference to the steel that is least susceptible to corrosion. Particular attention should be paid to the thickness of the rods for the nets, which should be from 1 to 6 mm. By the way, in situations where it is difficult to bend the mesh, a hammer will come to the rescue.

The algorithm for making a simple spark arrester is as follows.

- Removing the dimensions of the chimney and creating a sketch of the future fixture.

- Construction of a cardboard layout (optional).

- Purchase of finished or production of a mesh.

- Docking of structural elements and mesh.

- High-quality processing of all joints.

After completing all the above operations, you can, if necessary, assemble a homemade deflector. To do this, you will need to cut a visor of the appropriate size and bend it at a certain angle, taking into account the design features of the spark arrester. It remains only to fix the resulting element at the base of the device being created using rivets or welding.

Installation

The performance characteristics of any spark arrester are directly determined by how competently it was selected and installed. First of all, you need to pay attention to the correspondence of the sizes of the fixture and the chimney. Otherwise, installation will be seriously complicated or even impossible. If welding is used to connect individual structural elements, then all joints must be carefully cleaned. In addition to the inconsistency of dimensions, the list of the most common and gross mistakes includes an attempt to "tightly" fix the spark arrestor on the chimney.

It is important to remember that the installation height of the cone canopy must be within the minimum values stipulated by current regulations. In this case, it is necessary that the mounted structure does not violate or worsen the draft, but at the same time prevents precipitation and debris from entering the chimney.

To perform all the necessary calculations, you can use special tables or seek help from experienced specialists.

As already noted, the static installation of a spark arrester using welding machines is strictly prohibited, since this device must be removable without fail. This requirement is due to the need for periodic maintenance of the system. In addition, the nets often burn out, which provides for their replacement.

Care and maintenance rules

Despite the maximum simplicity of the design and operation scheme (the exception is water models), the operation of spark arresters provides for routine maintenance. And in this case we are talking about the following key operations.

- Inspection of the system for mechanical damage and structural integrity. Held at least once a year.

- Removal of soot and other deposits from key elements at least every six months.

- Unscheduled inspections and cleanings as needed. Such events become regular, for example, in regions where a large number of poplars grow. The fluff of these trees is capable of creating a solid and sufficiently dense fiber on the nets and perforated elements of spark arrestors. As a result, not only the device itself becomes useless, but traction also deteriorates and the level of fire hazard increases.

- Replacement of individual parts of the structure when damaged or burned out. As a rule, components made of ferrous metals are susceptible to corrosion. This is most important with significant temperature fluctuations. By the way, that is why it is preferable to install stainless steel models.

It is important to remember that in the overwhelming majority of cases, all of the listed works belong to the high-rise category. Taking into account all the features and objective risks, they should be carried out in strict compliance with the relevant safety regulations.

How to make a spark arrester with your own hands, see below.

The comment was sent successfully.