Knauf Betokontakt primer: characteristics and application advantages

Knauf Betokontakt primer is used for interior and exterior decoration of premises. Its composition allows the product to be used on any substrates with different indicators of density and surface smoothness. The main components are polymers and quartz chips. They increase the adhesion of the coated surface, waterproofing and fire resistance of the walls.

Knauf Betokontakt primer: characteristics and application advantages

The main tasks of the Knauf Betokontakt primer are the adhesion of the plaster to smooth surfaces and the creation of a reliable, durable coating. It is functional, simplifies many stages of work associated with surface preparation and dismantling of the previous coating.

If earlier it was necessary to use several different compounds, now one Knauf Betokontakt primer is enough.

Typically, this soil is used in working with building materials that have the following characteristics:

- high density (concrete);

- moisture resistance;

- smoothness (glass, ceramics).

But experts note that concrete contact has the following properties:

- strengthening of weak loose bases (drywall);

- increased adhesive properties;

- resistance to alkaline compounds;

- leveling the surface;

- elimination of microcracks in the base;

- adhesion to any material.

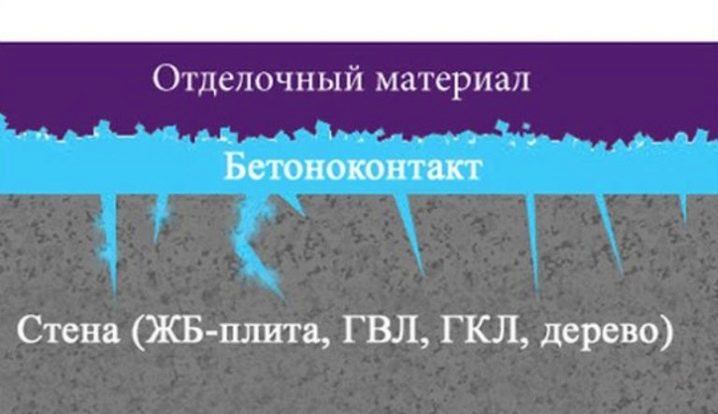

These qualities of the Knauf Betokontakt primer extend the range of its application. It is perfect for preparatory and rough work before applying plaster on surfaces made of concrete, cement, drywall, various metal structures. The primer adheres tightly to the base and forms a rough-to-touch film that provides a high degree of fixation of the subsequent coating.

When interior decoration of premises, concrete contact allows you to skip one of the mandatory stages of repair - dismantling the old coating. It can be easily applied to oil and alkyd painted walls, enamel surfaces and old tiles. Knauf Betokontakt can handle any challenge.

Manufacturers have created a universal composition, Knauf Betokontakt primer is used by specialists in working with wood, metal parts, decorative elements made of polystyrene. The resistance of the soil to alkaline compounds makes it possible to use plaster based on lime and gypsum.

General information about Knauf Betokontakt primer

Knauf Betokontakt primer is a ready-to-use mixture of pink shade. Produced in containers of 5 kg and a bucket weighing 20 kg. The shelf life is 18 months from the date of manufacture, open product can be stored for about 6 months in a tightly closed container.

The product has pronounced adhesive properties, used on surfaces of a complex nature - poorly absorbent, smooth, dense... It is used to strengthen concrete foundations, gypsum plasterboards, when preparing metal structures for further work (putty), while laying ceramic tiles, fixing stucco moldings made of polystyrene, gypsum, polyurethane. Concrete contact simplifies construction work and reduces the amount of additional consumables due to its strengthening properties. Primer Knauf Betokontakt smoothes surfaces, removes minor defects in the base, microcracks.

Working with Knauf Betokontakt soil requires adherence to a certain temperature regime.It cannot be used at temperatures of –5 degrees Celsius and below, in frost, as well as when the thermometer is above + 26-27 degrees Celsius.

The coating is applied in two layers, each drying time is about three hours, but experts recommend continuing work after 12-20 hours. You can make sure that it is dry by touching it with your hand, the base should not be sticky.

Knauf Betokontakt primer is available in two types - with mineral particles of 0.6 mm and 0.3 mm. The first type is used in rough finishing and coating of external surfaces, the second is used for more delicate work and before puttying.

When calculating the consumption of the required material, several factors should be taken into account:

- the degree of moisture absorption of the base;

- surface type;

- number of layers;

- method of application.

On a smooth surface such as paint and varnish and ceramic, the consumption of primer will be significantly lower than when applied to a concrete slab. The minimum consumption is approximately 200 g. per 1m², maximum - 350 gr.

Manufacturers release the mixture in a completely ready-to-use condition... Experts allow the Knauf Betokontakt primer to be diluted with a little water for better mechanical application.

When applied by hand, the maximum amount of water to dilute is 50 ml per liter of primer... The mechanical spraying method uses a 2: 1 dilution - two parts of soil, one part of water.

Another option for soil dilution is also offered, with this technology, material consumption is reduced, but the quality remains at the same level. The coating is applied in 2 layers. The first layer consists of a mixture of concrete contact and deep penetration primer. The second is Knauf Betokontakt in its purest form.

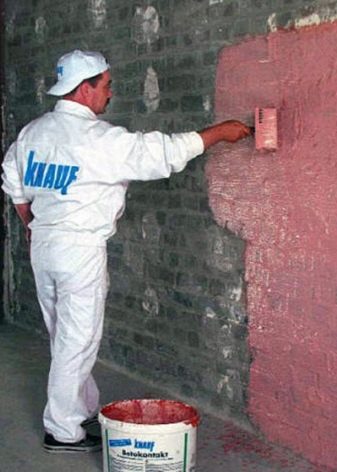

Before starting work, the mixture must be thoroughly stirred so that all microparticles are distributed evenly over the entire area. When processing the surface, you can use any tool - brush, roller, mechanical spray... The pink color will help you see the blurry areas.

Technical properties and characteristics

Experts have long and widely used products of the Knauf brand, the Knauf Betokontakt primer is no exception. Its unique ability to bond materials of different density and smoothness allows it to be used in different types of work.

Basic properties of Knauf Betokontakt primer:

- durability;

- waterproofing;

- fast drying;

- alkali resistance;

- uniformity of application;

- resistance to temperature extremes;

- mold and mildew resistance;

- high fire resistance;

- environmental friendliness.

The manufacturers stated that the concrete contact will have a lifespan of 80 years. After that, damage to the surface and its complete destruction may occur. At the moment, these data have not been confirmed, since the product entered the market not so long ago.

On the treated surfaces, a thin, durable waterproof film forms, which increases the waterproofing performance. This property distinguishes concrete contact from other soil mixtures.

During the development of the Knauf Betokontakt formulation, additives with fungicidal properties were included. They protect the coating from the occurrence of fungal diseases and mold. This point should be taken into account when buying additional finishing materials.

The primer allows you to maintain the optimal rate of air exchange between the room and the street, vapor permeability does not decrease. It can be applied to vertical, horizontal surfaces, floors and ceilings. The ability to plug porous substrates and micro-cracks reduces material consumption, prevents plaster delamination or cracking of other subsequent coatings.

The temperature range from -40 to + 60 allows the use of the solution for internal and external work. The composition is completely safe for humans and does not contain toxic substances. The acidity of the soil is within the normal range - pH 7.5-8.5. Average consumption rates are 0.35 kg per 1 m².

Natural ingredients that make up the soil mixtures do not cause irritation, do not have an unpleasant odor, it can be used indoors without fear for your health... Gost meets Russian and international requirements.

Surface preparation before application

The application of Knauf Betokontakt primer does not require professional training, which allows it to be used at home. Surface treatment is allowed in two ways: classical, carried out with brushes, rollers or a spatula, and mechanized.

First, it is necessary to thoroughly clean the base from dust, dirt, foreign small particles. Wherein it is not necessary to remove the old coating if it is well preserved, does not crack or crumble... Then the surface is degreased, inspected. Deep cracks and gaps are pre-cemented and left to dry for 24 hours. After that, the surfaces are primed. It is worth noting that the soil penetrates into the layers of the concrete base by several centimeters, strengthening it.

Buyers respond positively to Knauf Betokontakt soil mix, highly appreciate its quality, convenience and ease of application, economy and quick drying.

Knauf is a time-tested brand. This modern construction primer is popular with many professionals. Knauf Betokontakt guarantees quality and durability, it saves you money and time.

For more information about the types of primers and the intricacies of priming various surfaces, see the next video.

The comment was sent successfully.