All About Hydraulic Garage Presses

The number of cars on the roads is growing steadily every year, and this leads to the massive opening of auto repair shops. Many of them work in conventional garages. In order for a car service to provide quality services, a hydraulic press is required.

general description

A hydraulic press is a device that allows you to change the shape of a workpiece, compress, chop, and also perform a large number of other operations that require significant physical effort. The tool was most widely used in auto repair shops, but it can also be used to squeeze out juices, oils and press straw.

From a structural point of view, a hydraulic press is an aggregate that, by means of a liquid, transfers the force from a small cylinder with a piston to a cylinder with a larger piston. The force parameters at this moment increase in proportion to the quotient from the sectional area of the large cylinder to the sectional area of the smaller one.

The operation of the device is based on the law of physics deduced by Pascal. Following it, pressure has the ability to be transmitted to any point in liquid media without any changes. Accordingly, the pressure in two communicating cylinders of different diameters will depend solely on the size of the surface of the piston mechanism and the applied force. From the pressure difference rule, it follows that with an increase in the area of the cylinder piston, the generated force must also increase. Thus, the hydraulic press provides a significant power advantage.

Simply put, applying a small force on the smaller cylinder from the side of the large one, we get more force at the output. At the same time, the law of conservation of energy works 100%, since having received a bonus in strength, the user loses in motion - the small piston will have to be moved more strongly, which will eventually displace the large piston.

The performance of a hydraulic press is comparable to that of a mechanical arm. In this case, the force transmitted to the lever arm increases in proportion to the ratio of the length of the larger arm to the corresponding indicator of the smaller one. The only difference is that in presses, the fluid plays the role of a lever. And the applied force increases in proportion to the size of the working surface of the hydraulic cylinders.

Views

Before purchasing a hydraulic press, you need to decide exactly how often you plan to use it and for what purposes. And already with this in mind, select the best option for yourself. The garage hydraulic systems presented by modern manufacturers differ depending on the type of drive, the mounting option and the method of movement of the main supporting base.

Horizontal and vertical

These tools differ in their design features. Each product is equipped with a special pressing panel. Only in one case does it move horizontally, in the other it moves vertically.

Vertical models are relevant for pressing, as well as unpressing workpieces. Horizontal ones are in demand for bending and cutting. Such a press is relevant in waste disposal - it allows you to press plastic, textile waste, as well as feathers, corrugated packaging and waste paper.

Floor and table

According to the method of installation, hydraulic presses can be divided into floor-standing and table-top. The latter are easy to place in the garage on the workbench. However, in this case, they will occupy a large proportion of the working volume. The floor stands are set separately. It is convenient, but they also cost an order of magnitude more.

The floor-mounted press is as stable as possible. In addition, it is distinguished by an extended range of adjustment of the functional space. This allows it to work with a wide variety of workpiece sizes. The tabletop mechanisms can lift up to 12 tons. Floor-standing models have a higher carrying capacity - up to 20 tons. Such units are in demand in private garage car services.

They allow assembly and disassembly of working units, their management and bending, replacement of bearings, repair of the undercarriage of the machine, as well as work on small firmware.

Foot and hand operated

Most modern garage installations have manual controls. However, some manufacturers offer models in which the foot control lever is additionally installed. The lifting capacity of such a mechanism is high and reaches 150 tons. The advantage is the ability to perform manipulations using both hands.

The presence of foot control allows you to carry out all the work as accurately and efficiently as possible.

Pneumohydraulic, electrohydraulic models, presses with a manual hydraulic pump

Any hydraulic press provides a drive, this role can be performed by a hydraulic pump with a manual control option. In this device, the power part of the mechanism is responsible for the reciprocating movements of the functional unit. They are piston-type or plunger-type - it directly depends on the characteristics of the liquid medium that is involved in the operation of the equipment.

If mineral oil and other viscous compounds are used, then piston cylinders will be the best solution; water is usually used in plunger structures.

The machine, consisting of a pneumatic cylinder and a hydraulic booster, was named "pneumohydraulic". In such an installation, the force is created by the pressure of the oily liquid on the piston, and lifting is performed due to the compressed air flow directed to the piston. The presence in the design of the pneumatic drive in devices, the force of which does not exceed 30 tons, significantly increases the ultimate load and at the same time accelerates the movement of the pneumatic drive. This allows you to adjust the pressure with minimal effort, which improves overall efficiency.

Hydraulic models with an electric drive in garages are rarely used, they are mainly in demand in industry. In this case, the working force on the piston is supplied by an electric motor. The use of such a device greatly reduces the time for carrying out technological manipulations, and also allows you to perform actions that require increased power.

Selection Tips

When choosing a hydraulic press for a garage, you need to take into account the basic parameters of this device.

The presses can be adapted for different carrying capacities - from 3 to 100 tons. Devices intended for use in industry have a large carrying capacity. Usually 15-40 tons are enough for garages.

Presses can be designed with or without a pressure gauge. A pressure gauge is needed in cases where it is required to correct the force applied to the part. The device allows you to control the strength of the impact. However, this is only relevant for high power presses.

A key characteristic of the mechanism is the installation option. The most stable floor models, besides, they are distinguished by the maximum adjustment of the height of the functional space.This significantly expands the range of permissible work depending on the size of the parts.

And finally, when choosing a hydraulic press, you need to make sure that its frame is made of thickened steel. If the structure is less strong, the limit load threshold will decrease, and this will affect its operation in the most undesirable way.

Advice: the presence of an auto-return of the piston significantly reduces the cost of the physical forces of the master.

Manufacturing instruction

If desired, a hydraulic press for a garage can be made by yourself. This work includes 5 main stages.

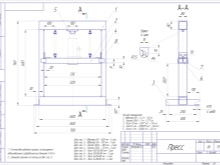

- First, you should draw up a drawing or layout of the main elements of the device.

- Then you need to make the main parts from rolled metal. To do this, make the necessary holes in them with a drill.

- Then you can proceed to welding the frame. Stiffening ribs are welded at the corners of the structure. The U-shaped frame is fixed to the base with bolts - the result is a frame.

- At the next stage, a working table is created from a metal sheet with a thickness of 10 mm. In order to ensure its vertical movement, it is necessary to make guides from a steel layer. Moreover, their width must exactly match the width of the frame. A pipe is inserted between the posts of the bed, then metal strips are substituted and the structure is pulled together on the sides.

- At the final stage, the tight-fitting springs are fixed. Pull out the work table before installing the jack. To do this, you need to form a stubborn socket, and then weld it to the center bottom of the table. In this case, the head of the jack will rest against the movable table.

This completes the work, the homemade garage press is ready.

Usage

Garage hydraulic press is relevant in cases where you need to straighten the element. The device can be used to prepare fuel briquettes that are required for kindling furnaces. The main advantage of using pressed sawdust is long burning time and no smoke formation. In addition, they provide powerful heat and thus provide the necessary heating of the room.

The hydraulic garage unit gives a good result when disposing of cans and bottles. By using the tool, waste can be quickly converted into compact formations.

The hydraulic press can be used for the hay baler. At the same time, the main structure is supplemented with a steel or glass frame without an upper block using specialized fasteners. This design can be fixed on the front, additional equipment is required (running element and transport pick-up).

When operating a hydraulic press, it is necessary to follow the rules of its maintenance. During operation, the volume of oil in the hydraulic chamber should be monitored. In addition, from time to time it is necessary to check the condition of the seals, the reliability of the fasteners of the structural elements and lubricate the moving parts.

You can see a detailed description of a homemade hydraulic press in the video below.

The comment was sent successfully.