Features of welding generators

The welding generator is an integral part of a converter or a welding machine and is intended for the production of electric current. There are several varieties of such attitudes, although by and large there are no significant differences between them. They differ in the kind of electric current produced, the time of non-stop operation, the specific purpose and other technical parameters.

What it is?

This device is a mobile power station equipped with an internal combustion engine (ICE), which produces electricity in an autonomous mode for arc welding or cutting. Simply put, this is a two-in-one unit - both an electric machine (generator) and a welding inverter that does not require connection to the electrical network.

At the same time, the installation itself can easily be used not only for electric welding, but also when there is no electricity at the facility as an autonomous power station. The device will also come to the rescue when there is an unstable electrical voltage in the network, and an ordinary inverter is simply not able to start.

This type of equipment as such is quite simple and convenient, as it functions without any kind of additional devices. In essence, this is a simple gasoline or diesel engine and an electric generator. By burning fuel, the motor forces an electric generator to function, which produces direct current.

Experts do not recommend practicing ordinary home modification to power the welding machine, since the electric current it produces may not be enough for electric arc welding. Although the principle of action is similar. In addition, it is necessary to distinguish between a welding generator and a welding unit. The latter is a combination of 2 independent options in one shell. It can be practiced on its own as a source of electricity or additionally use the welding option without being connected to the mains.

And a welding generator with an internal combustion engine simply generates a constant electric current required for an independent welding unit.

Species overview

Depending on the fuel, generators for welding can be gasoline or diesel. Let's consider each in more detail.

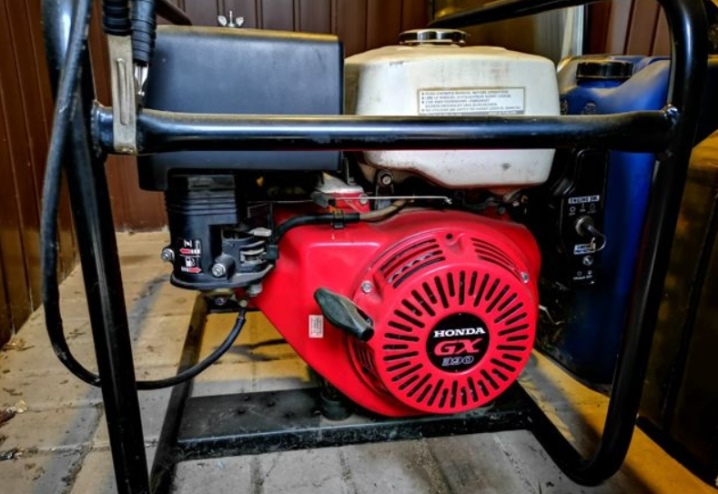

Gasoline

Among folk craftsmen and professional welders, this type of generator is especially in demand. It can be equipped with a 2-stroke or 4-stroke petrol engine. The device has a low power and is used for work with light loads. In addition, the gas generator is characterized by improved parameters of electric current, which have the best effect on the quality of the welded seam.

The power of gasoline samples ranges from 2.5 kW to 14 kW. The gas tank capacity of such devices is also small - approximately 4-25 liters. Such generators have the ability to generate the ultimate electric current on a scale of 160 to 300 A and are capable of operating with electrodes up to 5 millimeters in diameter.

The advantages of gasoline devices:

- reasonable price;

- light weight (from 50 to 100 kilograms);

- ease of use;

- the ability to start and operate in conditions of low ambient temperature.

Disadvantages of gasoline devices:

- short service life (from 500 to 3000 hours);

- impressive fuel consumption, for example, a 4 kW unit burns approximately 1.7 to 2.4 liters of fuel per hour;

- the unit needs to be given a break after a set time (noted in the manual for the device).

Diesel

Diesel generators make it possible to carry out welding operations with solid loads and have an impressive indicator of durability. Diesel devices are not suitable for household needs, since they have a power of 6 kW to 16 kW and are expensive. Stationary units can have power up to 80 kW.

The advantages of diesel generators:

- service life of approximately 40,000 hours;

- stability of work;

- metal welding at increased loads;

- high efficiency;

- with a power of 4 kW, less fuel consumption than the gasoline version of the generator - approximately 1.6 liters of fuel per hour;

- the diesel plant can operate without respite almost around the clock.

Diesel power stations are equipped with fuel tanks with a capacity of 12 to 65 liters, have an electric current of 160-520 A and are capable of operating with electrodes up to 8 millimeters in diameter.

Disadvantages of diesel installations:

- the motor is not easy to start in low ambient temperatures;

- large mass (from 100 kilograms or more);

- high price.

Popular models

On many construction sites, there is a need for permanent and reliable connections that require an electrical current of approximately 200 A. Such requests overlap 220 V generators one hundred percent.

We present especially demanded samples for 220 V.

- Fubag WS 230DC ES. The equipment has a sturdy metal tubular frame, powder coated for long-term resistance to rusting when working outdoors. The limiting welding electric current is 230 A, and a volumetric fuel tank of 25 liters is enough for a long-term process for 9 hours. In this case, welding can be carried out on an electric current of 150-160 A. The installation steadily generates 220 V and transforms it into a constant voltage. There is an electric starter for a comfortable start.

- Champion DW190AE. This successful modification of the welding generator perfectly combines a set of required characteristics at a reasonable price. The limiting power of the electric current reaches 180 A, which is enough for the overwhelming mass of work during the repair of equipment or in individual construction. The welding cable is securely fastened to the studs and fixed by means of wing nuts, which prevents unintentional breakage from being caught by the foot. The power is 4.5 kW.

- Huter DY6500LXW. This is a German welding generator with a robust body, where all the most important elements are located under the roof, which makes it possible to operate it outdoors even in rainy weather. The limiting power of the electric current is 200 A, and the power reaches 5.5 kW. To reduce the final price, the manufacturer had to install common components and the smallest configuration. Starting is carried out both manually and by means of an electric starter.

For serious construction, where thick metal is used, more powerful equipment is needed, which is capable of conscientiously boiling metal or cutting. See an overview of popular 380 V.

- Mosa TS 200 BS / CF 27754. If a 3-phase source of electric current is required at the workplace, but the necessary funds are not available for a powerful unit that has many functions, then the choice falls on this device. It generates a constant voltage with an electric current of 190 A for 3 phases. The equipment from Italy is provided by a Japanese Honda motor. Only the cost was reflected in the functionality and equipment. But the manufacturers endowed the device with a decent power - 8.3 kW.

- EuroPower EP300XE. The welding power plant has solid parameters for demanding construction and installation work.The installation produces 2 streams of voltage, which is distributed to electrical outlets of 220 V and 380 V. At the same time, a constant electric current of 300 A is generated. The power of the power plant is 7 kW. A large-sized power plant is heavy. It is designed for stable operation throughout the entire construction period.

How to choose?

Choosing a gas generator for welding

When choosing equipment that generates electricity, in addition to the required power, it is necessary to pay attention to some parameters that distinguish units operating on gasoline from others.

It is preferable to buy a station with a welding unit integrated inside. Equipment with a built-in unit for the implementation of welding processes in the future can be used as a source of backup (guaranteed) power for the house. By the way, for amateur welding, as well as for all household needs, a power of 5-10 kW is enough. The positive aspect of such modifications is that a voltage is generated at the output that one hundred percent meets all the required characteristics for welding.

Engine's type.

- 2-stroke engine costs less, and therefore, as a rule, is used in home (amateur) modifications of generators. During continuous operation, 2-stroke units overheat and have other limitations, however, their productivity is sufficient to carry out the necessary work on the farm.

- 4-stroke motor more powerful, has a water cooling system. A gasoline-powered installation with a built-in welding unit with a 4-stroke engine will serve for a long time, although its cost is much higher than that of a conventional model.

The demand for gas generators is due to the high quality of the voltage produced. The quality of the produced electrical energy is mainly associated with the peculiarity of the functioning of internal combustion engines, which provide a more measured transmission of torque to the rotor of an electric machine.

And one more significant factor. For household needs and welding work, inverter generators are perfect. They are the most economical and have some advantages to practice them with maximum impact:

- measured supply of voltage in the process of work;

- automatic correction of voltage drop during no-load;

- increase in voltage supply under load.

How to choose the right welding diesel generator

The scheme of operation of a welding diesel generator is for the most part similar to that practiced by equipment operating on gasoline. However, in order to in order to be able to apply the generated voltage for welding operations, the use of auxiliary equipment will be required.

The disadvantages of diesel power plants for connecting welding equipment are a strong wave of the generated electric current, the lack of a stable output voltage. In this regard, the manufacturers themselves do not recommend the use of diesel equipment for connecting autonomous welding machines.

It is necessary to purchase diesel generators in such situations.

- Several welding units are connected to one point at once. The lack of voltage in this situation can be neutralized only by diesel engines.

- Saving fuel. When welding is a key activity for the installation team, then diesel power plants will provide the opportunity to reap significant benefits on fuel consumption. Diesel engines are much more economical.

- The duration of the offline operation. It is better to purchase a diesel generator with an integrated welding function when it is expected to be actively used throughout the entire work shift or even over a number of working days.

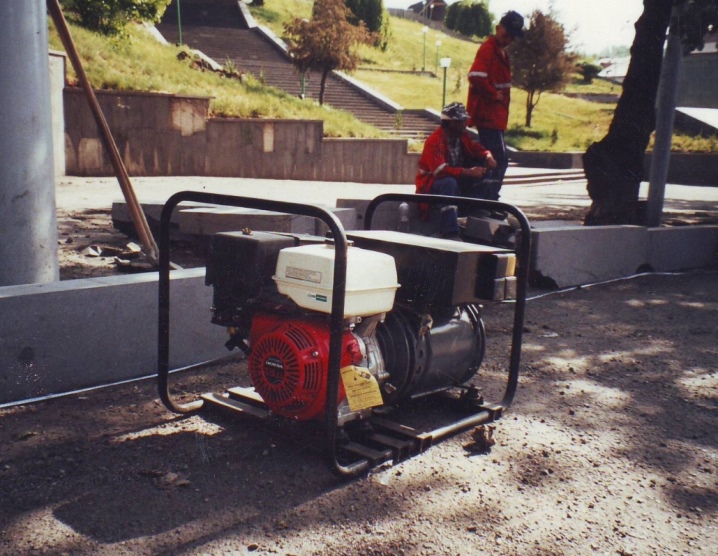

Separate power stations for practicality are located on a frame with wheels, with a towing device. In industrial power plants this way increases their transportability and, consequently, their area of use.

The choice of a gasoline or diesel generator mainly depends on the practical needs of the consumer and the intensity of operation. Both the first and second options have their own advantages and limitations associated with the operation.

The following video provides an overview of the welding generator.

The comment was sent successfully.