The foundation for the barn: which is the best to choose and how to make?

The foundation is needed not only for houses and cottages, but also for outbuildings, which include sheds. Such structures are often erected on a solid foundation. With this addition, buildings become taller and stronger. It is worth figuring out which foundation is more suitable for a shed and how to install it yourself.

Features of the choice of the base

Today there are several types of foundations. Each of them has its positive and negative sides. For the shed, you need to select the foundation as carefully as for the main structures on the site.

To dwell on one option, you should rely on the characteristics of the soil.

- For loose, sandy soil, one serious problem is characteristic: after melting snow or heavy precipitation, such soil is saturated with moisture. This can lead to the fact that he just "float". In these conditions, professionals advise to build a monolithic or tape base.

- As for the clay soil, then it must be borne in mind that it is prone to freezing at a considerable depth. Quicksands are also formed under similar conditions. For such a soil, a pile base is more suitable.

- The negative sides of frozen soil and quicksand are unfamiliar to gravel-type soil. In such conditions, it is possible to safely mount a columnar foundation.

- There is also a special rocky soil type. Any kind of foundation can be built on it. The only exceptions are screw bases.

In order to choose the optimal type of foundation, it is important to take into account the topography of the soil, as well as the level of groundwater. To find out all the necessary information about the site, you should contact the specialists. However, it is worth considering that such geological surveys can be quite expensive, which is why most homeowners rely on the experience and advice of their neighbors. There is a way to independently study the soil to select the optimal foundation. For this, a trial screwing in of a screw pile is done. At the same time, this part goes deep into the ground manually, so that it is possible to determine the level of groundwater, as well as the depth of the bearing layer by the moment of the screed.

Preparatory work

Before proceeding with the construction of the foundation for the shed, it is necessary to carefully prepare the site in the place where the outbuilding will be located.

At this stage, the following work should be carried out:

- you need to properly level the place where the foundation with the barn will stand;

- remove everything unnecessary from the ground: hemp, twigs, dirt, trees, bushes and other similar objects.

After clearing the land for each type of foundation, its own work is carried out. For example, a large pit is dug for a monolithic foundation, and a trench must be prepared for a linear foundation. If the site has too uneven ground or soil with a steep slope, then it will not be so easy to level it. In this case, experts recommend installing foundation structures on piles.

The subtleties of manufacturing

The foundation for the shed can be made by hand. You should consider in more detail several simple instructions with a step-by-step description of the installation of the foundations for this outbuilding.

Screw

Screw bases are erected as follows:

- first, along the perimeter of the walls, you need to set the markings for screw piles;

- then you need to dig out small grooves, between them you should leave about 1.5–2 m; piles must be placed in the prepared holes, which should be located in the corners; if the structure has internal partitions, then the piles must be fixed along the line of their construction.

- if the plans are to lay a floor of boards in the barn, then the piles need to be placed under the logs;

- it is necessary to screw in large piles that have a diameter of more than 100 mm and a length of more than 150 mm, it should be borne in mind that such installation work is carried out with special equipment;

- piles of more modest dimensions are screwed into the soil manually using levers, while it is necessary to ensure that the foundation structures are in an even vertical position;

- the fixed piles must be cut in height, for this it is recommended to use a bubble or laser level;

- cement composition must be poured into the pipes;

- at the top of the piles, it is necessary to attach the heads; in one structure, the foundation is assembled by a channel welded along the perimeter or an I-beam.

Columnar

To build a similar foundation for a farm building, You may need the following materials:

- concrete mortar, which will need to be poured into the formwork;

- metal or asbestos pipes with reinforcement, filled with concrete mortar;

- brickwork;

- but;

- concrete blocks.

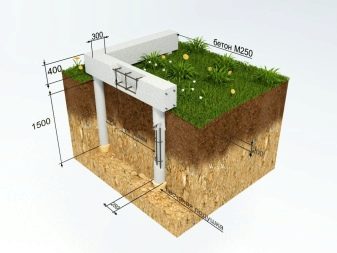

The foundation with pillars-pillars for the shed is built in a different way than a screw one, and includes the following steps:

- to install the supports, you need to dig depressions of suitable depth, relying on the markings drawn up before;

- the gap between the supporting parts should be left in the range from 1.5 to 2 m;

- the depth of the foundation structure for the outbuilding must be at least 150 mm below the freezing point of the soil;

- it is necessary to sprinkle coarse gravel (about 100 mm) on the bottom of the pits, in addition, pour the same amount of sand; these materials should be compacted, and then roofing material should be laid on top;

- supports should be placed at the same level, they should be located about 150-200 mm above the ground;

- on top of the supports, you need to put several layers of waterproofing;

- the pillars must be surrounded by a blind area so that the soil is not washed out.

Tape

Tape foundations are the most popular because they are inexpensive, easily withstand impressive loads and are versatile.

To prepare such a base for a shed, you should follow these steps:

- along the perimeter of the outbuilding, they dig a trench with a depth of 200–300 mm below the level of freezing of the soil;

- the indicator of the width of the trench depends on the size of the base; free space should be allocated for the installation of the formwork;

- it is necessary to equip a cushion of crushed stone with a thickness of 100 mm, and then tamp it well;

- sand should be poured at the bottom of the trench and also tamped;

- now it is necessary to prepare the formwork with the upper edge rising 200-300 mm above the ground;

- the formwork must be reinforced with struts, while the upper extreme part is knocked down by transverse bars with a step of 1.5–2 m;

- inside the formwork on the walls, you need to put roofing material or polyethylene;

- it is necessary to carry out reinforcement, for which steel rods with a diameter of 8–12 mm are useful; the reinforcement must be put and tied so that a lattice with cells of 40-50 mm is obtained;

- it is necessary to pour concrete; to get rid of air bubbles, reinforcement must be stuck into the concrete several times over the entire pouring surface;

- the setting concrete should be covered with plastic wrap and moistened from time to time so that the material does not crack;

- after 28 days, when the concrete hardens to the end, the formwork must be removed and the trench must be backfilled with earth;

- two layers of waterproofing should be placed on the concrete fill.

According to DIYers, this foundation is pretty simple. Its construction is not difficult.

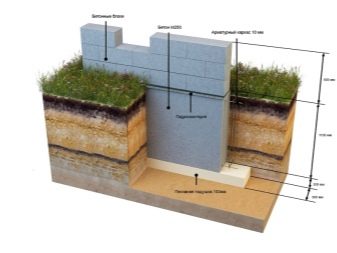

From foam blocks

The foundation of blocks (foam or cinder blocks) is strong and reliable.

It is assembled in several stages, namely:

- first you need to mark the site and dig trenches of the required depth;

- the bottom of the trench must be leveled and tamped;

- the next step is to arrange a cushion of gravel and sand;

- after that, the blocks can be laid out in the trench; for this, you should contact the services of special lifting equipment;

- a cement-sand mixture should be applied to the side walls;

- each next block row must be laid with a slight offset of half the length compared to the previous one;

- in the space dividing the rows, you need to apply a solution of sand and cement;

- at least 1 row of foam blocks must be laid above the ground;

- above and on the side, you need to apply bituminous mastic using rags and kwacha;

- in conclusion, you need to backfill the trench with earth.

Monolithic

The monolithic base is reliable and strong. It can be used on almost any soil. On this basis, a shed of any size, from very small to large (for example, with dimensions of 6x4 m), will stand for many years.

The technology for the construction of this type of foundation includes the following stages:

- a hole must be dug under the entire territory of the fill, while its depth should be only 0.5 m; after tamping, sand (200 mm) must be poured onto the bottom, in addition, the sand must be slightly moistened and tamped;

- crushed stone is laid on the sand layer (a layer of 200 mm) and also compacted;

- floor slabs are laid on the resulting sand and gravel cushion and prepared for pouring, for this formwork is assembled and reinforcement is made; in this case, the cells in the lattice should be 20x20 m, then the formwork is poured with concrete;

- you need to expel air bubbles from the solution, which should be done using a special vibrating press;

- put a polyethylene layer on the frozen solution;

- the formwork can only be removed after 28 days.

Useful Tips

Experts recommend there are some tips to follow when creating the foundation for your barn.

- An outbuilding of a large area will require a sectional layout. In this case, the foundation is poured not only along the edges of the building, but also under it, so that the bottom of the shed does not sink over time, but simply lies on the concrete.

- The cement dries out completely on average in 24-28 days, however, it is permissible to start the construction of an outbuilding earlier - after a few weeks, when the strength of the pouring has been reached by more than half.

- If a columnar structure is mounted on heaving ground, then it should be borne in mind that it should lie deeper than the freezing of the ground.

- If you want to save money, then instead of asbestos pipes and roofing material, you can use simple car tires. In conditions of non-porous soil, they do not need to be greatly deepened. The cavity of these objects should be covered with sand, and then filled with cement.

- Do not forget that the columnar foundation for the shed must be waterproofed and drained without fail.

- Experts recommend making the required calculations and measurements in advance, as well as preparing all the necessary deepenings on the site. And also you need to decide on the number of the foundation pillar. Otherwise, you can face serious problems. For example, in the midst of work, it may turn out that there are impenetrable rubble knots in the ground.

- Screw piles can be made slightly longer if necessary. For this, the ends at the top are supplemented with threads and grooves.

- It must be remembered that the heaving does not affect the piles in any way, since their outer surfaces are treated with an anti-corrosion agent. However, in this case, the building receives an underground, the perimeter of which must be closed with decorative material, for example, siding, tiles or corrugated board. To ventilate the underground, the intake is equipped with ventilation ducts.

- The shed must be built immediately after the completion of the work related to the foundation. Otherwise, the swelling of the soil, which occurs in the spring, may slightly move the pillars from their original point.

- For outbuildings, it is permissible to erect combined types of foundation foundations, for example, a columnar base with a grillage. To make it, you need to fill in a shallow strip foundation with recesses for supporting parts located in the corners with a step of 2 m.

- Block foundations are made from different types of blocks. Most often, there are structures made of cinder blocks and foam blocks. If you decide to make the base from the first, then you need to know that such materials have a porous structure, which contributes to their rapid destruction under the influence of moisture.

- When making the foundation with your own hands, you should rely on the instructions. You should not neglect any of the stages of work.

- When erecting the foundation for a farm building, you should not make any mistakes, as this can affect the reliability of the entire structure as a whole. If there are doubts about your abilities, then it is better to turn to professionals who, for a fee, will make a high-quality and strong foundation for any outbuilding.

For information on which to choose and how to make a foundation for a barn, see the next video.

The comment was sent successfully.