Plywood wall decoration

Wall cladding inside summer cottages, houses and apartments can be made from a variety of materials. Finishing with plywood sheets has been popular for more than a decade - it provides a dense and practical basis for further decorative design. In work, ordinary and decorative panels are usually used, depending on the technique of work, installation is carried out on glue or a frame structure.

Peculiarities

Plywood is a material well known to many of us. Until a few decades ago, it was one of the main options for ennobling living quarters. Nowadays, the use of plywood panels for interior decoration has not lost its relevance due to the interesting texture and high technical and operational characteristics. The advantages of plywood include:

- the rigidity and strength of the surface - the panels are much stronger than, for example, drywall;

- environmental safety - plywood is made from veneer;

- lightness - low weight determines the simplicity of loading, transportation and direct laying of plates;

- plywood sheet allows for wall decoration options;

- the material has exceptional soundproofing characteristics - this is especially important when installing floors;

- affordable cost.

There are several types of plywood sheets, which differ in their operational parameters. They all have different areas of application. For example, if you want to use wall slabs as a lining for some other facing material, then you can get by with the most budgetary proposals.

What plywood is used?

When carrying out repair work in residential and business premises, ordinary or decorative plywood is used; to achieve the most effective result, the plates can be combined. Ordinary plywood is made of sheets glued together, with different number of layers. For cladding, 2 grades are predominantly used.

- FC... For gluing sheets, urea compounds are used, which have increased resistance to moisture. Thanks to this, the material can be installed in rooms with high humidity levels. This solution is optimal for utility rooms, near the stairs, as well as in summer cottages.

- FBA... To veneer the plywood surface, use casein-albumin glue. This option is often chosen for wall cladding in children's rooms and bedrooms, since it is considered the safest in terms of environmental friendliness. Among the disadvantages, one can note the low moisture resistance of such sheets, which is why they must be treated with special protective impregnations over the entire surface, as well as in the areas of joints.

For plywood cladding of any vertical bases, preference should be given to products with the E1 emission category. He points out the safety of facing tiles for the life and health of people and pets.

The size of a typical plywood sheet is 1525X1525, the thickness of the boards varies from 9 to 12 mm. To reduce the cost of the material, plywood is produced in several graded categories. If you will be using the panels exclusively for leveling the walls for further cladding with decorative products, you can buy grade 3 or 4 plywood.For cladding household premises, it is better to choose products of 2 quality categories: there are cracks on the surface of these sheets, so the material needs additional puttying.

If the plywood sheets will act as a finishing sheathing, grade 1 panels will be needed. You can also find the elite category of plywood on sale. However, it is used quite rarely. This is due to her low prevalence in stores and a very high price.

Plain plywood sheets are traditionally made from hardwood as well as softwood... Deciduous trees have good decorative characteristics and high durability. Nevertheless, it is better to give preference to products made from spruce or pine: they are lightweight and affordable. The most successful solution would be combined panels. Decorative plywood sheets are laminated products, they are presented in the following types:

- F / F - decorative coating is applied on both sides, the surface of the sheet is smooth;

- F / W - the coating is applied over the entire surface of the slab, the outer part is smooth, and the inner part has a fine mesh structure;

- SP / SP - the processing of such plywood resembles the first method, such surfaces are usually designed for further coloring;

- F / SP - an alternative version of plywood with a smooth side, optimal for painting, for applying paints, enamels and other coatings;

- F / U - the cheapest type of decorative plywood, the film is provided exclusively on the front side.

To create a stylish decor in a room, they usually choose plywood with a wood structure or plain boards. Solutions with a carved structure or perforation look quite stylish. Plywood veneer decorative wall panels are produced in different sizes, this directly depends on the type of coating and the manufacturer.

Surface preparation

Most often, plywood wall cladding is performed in attics, in summer cottages, as well as in utility rooms. The process is quite simple, but special attention must be paid to surface preparation. In a wooden structure, such upholstery can be made without preliminary installation of the frame, of course, only on condition that the vertical surfaces are perfectly flat.

If they are curved, then first you need to make a frame structure from a bar.

If you intend to trim concrete bases with plywood, then the frame is mandatory regardless of whether the surfaces are even. The beams give the structure the required level of strength and ensure the fixation of the plywood layers so that all joints fall exactly on the crate.

If plywood slabs are bought for cladding balconies and loggias, then preference should be given to waterproof materials, since in the inclement season the frame will be exposed to precipitation and low temperatures. In some situations, plywood sheets are laid on the insulation, the indent from the vertical surface should be 1.5–2 cm more than the thickness of the insulation layer. The best solution would be to use mineral wool. It has high thermal insulation characteristics, is lightweight, and does not succumb to pests.

Mounting options

Before laying the plywood with your own hands, you first need to prepare the base and the working tool. The complex of works includes cleaning the surface, treating the coating with special impregnations from mold, as well as fungus and rot. In addition, wooden surfaces must be additionally impregnated with fire retardants that protect against fire. All other activities are carried out only after the final drying of the walls and plywood.

On the crate

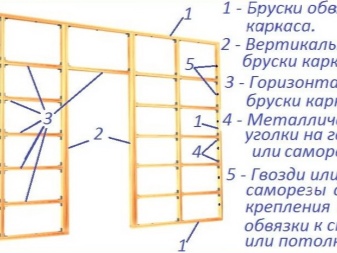

Arrangement of the frame is considered the most common solution: it allows the alignment of the bases even with very strong curvatures. Installation of plywood boards is carried out on a beam.Alternatively, you can consider installing galvanized profiles. The first method is optimal for wood and brick buildings, the second technique is preferable when working with concrete in cold rooms. The walkthrough includes several steps.

- First you need to prepare all the elements of the crate... The beams must be pre-treated with protective impregnations, as well as drying, depending on the surface variant and characteristics of the object. Additionally, you may need to install steam and waterproofing.

- Next, a conditional marking of the skeleton risers is made... They are placed taking into account the dimensions of the slab and cutting. A very important requirement: the edges should not be located over the voids.

- The fixing of the lathing begins with the installation of the upper and also the lower beams... All parts should be aligned with each other, indents from the walls are created taking into account all irregularities.

To sheathe a wooden base with plywood, you can use screws... When working with hard surfaces, the crate is attached to the dowels. The uprights should be set in increments of 450 to 500 mm. For fixing to the wall, the technique of direct contact is usually used, or metal suspensions are used. All parts are set at the building level, while any irregularities are corrected by means of substrates. All internal space is reinforced with lintels.

Self-tapping screws are required to secure the lathing, their core should be at least 3 times longer than the plywood layer itself. The panels are placed in several rows in a checkerboard pattern so as to prevent overlapping joints horizontally. Screws are screwed in with a step of 17–20 cm, the indents from the edges should be 25 mm, the areas in the center are also fixed at a distance of 25 cm. The hats are immersed flush. If plywood sheets are to be used for finishing cladding, countersink must be done first. When carrying out work, it is imperative to provide for 10 mm gaps from the ceiling and floor line. The main parts must be fitted with the smallest gap.

On glue

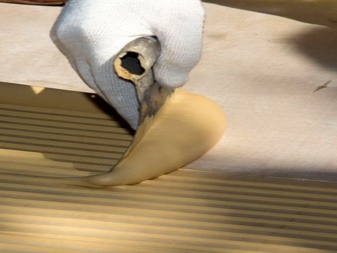

Bonding the slabs with glue is a little more difficult. In this case, the coating must certainly undergo thorough preparation in order to exclude any defects. Additionally, the surfaces are coated with a primer. To veneer the base with plywood, you need to follow simple steps.

First, an adhesive solution is prepared, it is advisable to take two-component mixtures: they provide the most durable adhesion. For cladding, panels are selected, the inner side of which does not have any cladding. It is not worth taking a laminated double-sided sheet, since the coating will have to be sanded.

To veneer the walls with plywood for glue, it is necessary to exclude the presence of dirt and dust on the base.

Adhesive mortar can be applied exclusively on the back of the panel, after which the product is pressed tightly. A joint is formed between the elements with a gap of 2-3 mm. It is very important to observe the distance from the ceiling, as well as the floor and adjacent walls. To increase the strength at the edges, you can screw in a dowel or self-tapping screw.

Decorating

Finishing plywood cladding may include one of the options.

- If high quality decorative panels were used, then the surfaces can be varnished.... To give the coating the desired shade, the plywood is pre-treated with stain, and the joints are sealed with glue with wood chips or sawdust.

- Dyeing... A rather interesting effect can be achieved by using several tones at once and at the same time highlighting the swirls with color.

- Wallpapering - is carried out according to standard technology.

- You can make the design more fashionable by applying a pattern to the surface of the panel. To do this, you can use a stencil or, if you have artistic ability, create a composition yourself.

- You can decorate the plywood coating by firing with a gas burner.

To refine the plywood and create the necessary entourage in the room, special attention must be paid to the correct selection of lighting.

For information on how to mount plywood on walls, see the next video.

The comment was sent successfully.