All About Two-Component Epoxy Resin

In various fields of industry and construction, a special epoxy resin has found wide application. This synthetic substance, which is produced on the basis of different epoxy groups, often acts as a super-strong and high-quality adhesive composition. Today we will talk about the features and properties of a two-component epoxy resin.

Peculiarities

Two-component epoxy resin is a special oligomer that, when combined with special hardeners, forms a crosslinked polymer that completely changes its physical characteristics. This resinous substance has a rather complex chemical formula.

The composition of the resin, due to its polymer composition, is an excellent means for reliable bonding of various surfaces of different density to each other.

At the same time, it provides the most robust and durable connection.

Difference from one-component epoxy resin

The main difference between these two varieties is primarily in the curing system and surface application. One-piece models are cured with moisture from the base and air. Moreover, the speed of this process will depend mainly on the level of air humidity.

Two-component epoxy will cure through a special chemical reaction. It occurs between the main components, including the hardener.

In this case, the speed of the process will depend on the temperature of the material and the environment.

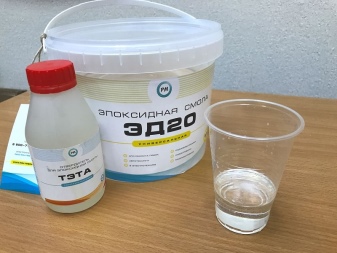

Composition

The composition of a two-component epoxy resin contains the following components:

- microspheres, as well as fine-grained elements belonging to this group;

- cotton and glass fibers, designed to impart greater density and viscosity to the mass;

- powder components - asbestos, chalk and cement;

- wood chips made from natural wood are necessary in order to reduce the specific gravity;

- aerosil to minimize the amount of smudges;

- coloring additives such as graphite, titanium dioxide.

Views

Currently, there are many different models of this resin. Depending on the consistency, they are divided into several types.

- Liquid. This option is often sold in special syringes. Liquid resins should be gently squeezed out of the container and often come with optional spot attachments. These models make it possible to glue small elements together. Liquid samples do not need to be prepared for use, they are available ready-made.

- Pasty. These epoxy resins are produced in the form of a plastic mass, in their structure they will be similar to simple plasticine. Such samples can be easily cut with a small knife, then you will need to knead it a little with your hands and slightly moisten it with water, after which the material is ready for use. Remember that the finished mixture should be quite thick. After final preparation, the mass is gently applied to the surface of the material.

When choosing, be sure to consider the type of resin. For working with small parts, it is better to choose the liquid option. For a more durable connection of large materials, you can acquire a pasty appearance.

Applications

Two-component epoxy resin is widely used in fields such as mechanical engineering, automotive, paintwork. Sometimes it is suitable for the installation process, including when organizing the waterproofing of swimming pools.

This resin can also be used in the manufacture of various electrical devices, in the manufacture of products from fiberglass or fiberglass.

This material is often used by designers and masters of applied arts. Thanks to this 2-component resin, you can create various beautiful decorations, decorative pieces of furniture, small souvenirs and interesting wall clocks with your own hands.

The comment was sent successfully.