Installation of interior doors

The functional capabilities of the structure and aesthetic appeal depend on the quality of the installation of interior doors: in any house or office, inspection of the premises begins from the doorways. Experienced specialists will quickly carry out measurements, offer the most optimal options, and carry out the installation in accordance with the design features.

It is also important to eliminate gaps by foaming with high-quality sealants, leveling the walls at the initial stage of installation and choosing a suitable model of domestic or foreign production.

Installation features

Installation of door frames is carried out at the final stage of the repair. After gluing the wallpaper, work is carried out to install the door frame in accordance with the technical rules and safety requirements. Installing a door in a large opening without anchors and additional elements requires a professional approach: experts recommend not to carry out this work yourself. Once upon a time, dampers were used as door structures to prevent cold air and moisture from entering the room.

Nowadays, doors serve not only as an entrance and exit area, but also as an effective addition to the interior design that can serve for many decades if properly used.

Knowledge of technology allows you to organize installation at a high technological level.

To install the structure you will need:

- form a block and equip the canvas;

- prepare material for use in conjunction with fittings;

- pick up hinges (with a regular handle or with an automatic latch).

In the opening, a block is mounted on which the canvas is equipped. Experts recommend pre-adjusting the mechanism. Platbands are a great way to give the structure style completeness and constructive unity, while it is advisable to use modern materials and the latest technologies. The activities are carried out in a strict sequence: during installation, actions are coordinated in accordance with building codes.

Plastic and metal-plastic installations are realized in a complementary form, prepared for the fastening process. The box is a collection of wooden blocks of different parameters, door leaves and special parts (strips) for platbands.

Collecting a box is a professional process:

- compliance of the measures taken with the operational requirements;

- use of proven materials and technologies;

- use of a U-base with a threshold.

For this purpose, bars are used (rack, loop bar). A base with a threshold requires the installation of a lower material of a certain thickness, while the assembled block must have a strictly geometric configuration. The craftsmen determine the dimensions of the doors, fix the format of the racks and lintels, taking into account the voids, cut out and design special bars.

Views

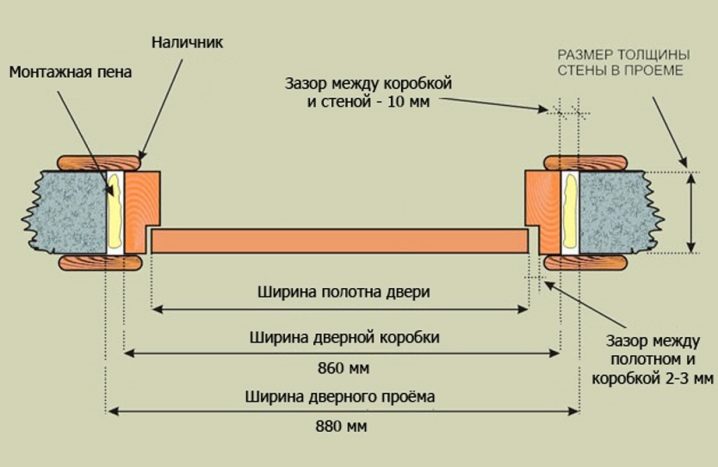

The dimensions of the box material must differ from the dimensions of the canvas. Measurements are made with simple tools, most often a ruler. The measurement of the canvas is carried out along the perimeter: you should not count on an external effect, since distortions are observed during the shrinkage process.Deviations play an important role in measurements.

The sequence of work is as follows.

- The parameters of the outer sides of the loop material are analyzed;

- The working parameters of the lintel, mock material are measured;

- The condition of surfaces in contact with the planes of the opening is diagnosed;

- Provides space for gaps (within 0.2-0.4 cm).

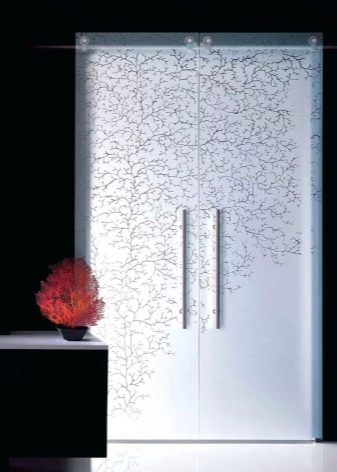

When installing glass structures, the parameters of the decor are additionally measured, the drawing is carried out using modern methods, if provided. Installation of sliding and double door installations is carried out in accordance with the technical requirements fixed in GOST. Roller doors will require additional measures related to the selection of a suitable model, installation of a structure that meets the standards and design requirements.

Hinged and sliding options are a great option for those who are used to saving space and relying on modern design. Experts will carry out preliminary measurements, select the most effective models and quickly carry out all stages of installation. At the request of the customer, installation of non-standard door structures and classic double-leaf doors is carried out.

Using these models, you can create an original interior design, equip any type of room (office, residential, warehouse). Subject to the installation parameters in an apartment, room or office, you can place dimensional furniture, which always looks fashionable and stylish.

Frames with a threshold acquire slotted holes along the perimeter in the plane of the door block without a threshold. Wizards will calculate points to eliminate vertical posts, provide sufficient parameters for the opening.

When arranging the box, you should pay attention to the following points.

- Correspondence of the size ranges of the "P" configuration;

- The quality of plasterboard materials;

- Competent carrying out washed down the timber.

The miter saw is effective when creating cuts; a hand hacksaw or self-tapping screws are often used. When installing doors, innovative technologies are used: the method of sawing down vertical racks involves adjusting the parameters of parts and lintels, while observing strict rules, the structure is adjusted at an angle of 45 degrees.

Competently carried out joining of parts gives the installation the necessary external format. The holes must be through, perpendicular to the cut.

Dimensions (edit)

When installing interior blocks, the question often arises of how to calculate swing doors for a niche. With small-sized walls, similar to the parameters of the door frame, finishing work is carried out using platbands. The formed set is installed on the sides of the box. This setting is designed to mask the foamed seam. Wooden or laminated platbands, if they are not processed, are installed using hardware, after which they resort to painting. Platbands may differ in shade from the plank, because contrasting options are always in trend.

The timber door frame is designed according to the construction requirements using cement-sand plaster. It is not recommended to install a canvas made of wood together with fiberboard boxes: different levels of moisture resistance can lead to deformation and cracking.

Structural blanks for screws in an MDF installation are made at the preparatory stage, drilling is performed with a tool with an optimal diameter. The size of the internal vertical bar level is calculated as the sum of the dimensions of the canvas (as a rule, 3 * 3 mm), if the structure is with a threshold. The ceiling piece is installed to special devices.

The use of self-tapping screws ensures high efficiency of work.The parameters are determined by indicators such as false and hinged materials, the distance is determined as the sum of the parameters used for the lateral voids.

The timber is made in accordance with the technical parameters at a right angle, since this is required by the arrangement of the threshold. The block is formed on a straight base (for example, on the floor).

The arrangement of door fittings must be carried out in such a way as to ensure evacuation measures. You can choose from right-hand or left-hand universal door hinges. Devices with a laminated surface are manufactured taking into account the parameters of the hinge. Usually, 20 cm is left as an indent from the top and bottom edges. The zone for installing the hinge to the box structure is determined taking into account the technological voids.

What material is better to put

Door products are represented by a wide range of models. Modern interior doors are made using MDF panels, progressive materials (WPC, eco-veneer, natural wood).

- Fiberboard Is a great option for creating an inexpensive and effective door. The wood frame is covered with laminated fiberboard sheets. These economical designs, easy to install and compact, are popular in the construction market. Experienced specialists will help to increase the resistance of the structure to high temperatures and humidity by using special formulations.

- MDF allows the manufacture of inexpensive and durable door blocks with optimal sound insulation performance.

- Wood it is characterized by high strength and resistance to the influence of aggressive media and mechanical stress. The porous structure of the material ensures the creation of an optimal microclimate. Such designs are great for author's design, perfectly complement the classic interior, while the parameters of the interior doors must correspond to the specifics of the opening.

All-glass doors, metal-plastic structures, steel parts are non-standard products that require an individual project.

Standard door systems are placed in a solid box, the quality of which determines the durability and reliability of the entire structure.

- Fiberboard box is a robust installation capable of deforming under the influence of mechanical stress.

- Box made of wood, untreated - structures made of profiled timber. They are distinguished by their super strength and reliability. When performing the installation, you will need to use additional materials for the final finishing activities.

- Box made of laminated materials. This installation does not require final finishing. The defining point is the nature of the lamination. The use of thin paper is not recommended, since in this case, scuffs and cracks may appear, affecting the external parameters of the product.

The doorway can be pre-treated. This determines the specificity of the opening, its parameters, and features of the interior of the room. Processing can be carried out using additional parts and platbands.

What tool is needed

Door installation requires the use of certain knowledge and techniques: a vacuum cleaner and a miter saw are considered indispensable attributes of the kit. Experts recommend at the initial stage to think over a plan of measures: it will be necessary to organize the marking, cutting of hinges, arrangement of door slopes.

Manual equipment and electrical equipment are used at the main stages of work. The question of how to use the router will be answered by experienced craftsmen with many years of experience, under whose guidance all the main activities will be carried out.

With the help of a punch, the working surfaces are leveled and the opening widens. This tool allows you to make special dowel indentations. The drill helps to drill the recesses of the required parameters for the fastener.The start of work is accompanied by a check of the equipment. The tightness of the drill is very important, because the part can fly out during work and damage the working surfaces of the doors.

The screwdriver allows you to securely fix the hardware in the hinges. The jigsaw is used to process complex surfaces that are difficult to cut. A hand-held electric milling cutter helps to install the locking mechanism and integrate the hinges. The pencil allows you to make special marks in places requiring processing. For the same purpose, a marker is used (provided that it does not leave marks on the surfaces).

A three- and five-meter tape or steel ruler, together with a checking square, ensure accurate measurements. Using a vernier caliper, the depth of the cut is measured, which is performed using a chisel.

The slope of the surfaces must be measured using a bubble level with parameters within 50 cm.Using a set of screwdrivers, hinges and awnings are attached, and locks are equipped.

The miter saw is an excellent tool for sawing structural parts - bars and platbands at an angle of 45-90 degrees. The circular saw helps to format the dimensions of the door leaf. The gun can be charged with a high quality sealant to close gaps.

What is included?

Self-tapping screws allow fixing device elements (mounting strips, hinges, platbands, locking mechanism). The kit also includes liquid and finishing nails and micro-studs, which are fixed with a pneumatic gun. With the help of these devices, the mount becomes ultra-strong and reliable. The mounting micro-stud is a compact hardware element without rivets, which provides a solid surface. You can measure the length and width using a tape measure or a metal ruler.

Interior doors are sold without fittings, which are known in domestic and foreign manufacture.

Experts will help you choose high-quality systems (hinges and locks) that are not subject to mechanical stress and corrosive deformation. By adjusting the hinges using fasteners and a screwdriver while working with slopes, it ensures a high density of adhesion of the canvas to the box, while using special devices that allow you to measure parts, insert structural elements at a high professional level.

The mortar bath is made of a special material that provides an optimal mixing format for building mixtures and ease of cleaning after work. The kit includes brushes and rollers for finishing work. The grout kit provides a reference surface view of the door block.

How to install correctly: step by step instructions

Interior designs are installed from scratch using step-by-step recommendations posted on Internet portals. Experts recommend not doing events yourself if you do not have sufficient knowledge and experience.

Experienced craftsmen will tell you at what stage you should carry out preparatory measures yourself, and at what stage the installation of the structure takes place.

- Determine the specifics of the means and the quality of consumables for the installation of the structure.

- Outline the installation scheme for the blocks of a double-leaf interior door with extras.

- Carry out constructive measures to install the door frame without self-tapping screws. Hinges are attached to the door block, a cutout is organized in the structure, a strong box is assembled, after which all the elements are assembled. Metal bases must be structurally sound. The planks are fastened using self-tapping screws. The U-shaped design is the key to well-done work.

- Mount the structure in the opening. The box is inserted into the doorway, alignment is performed. The end piece is drilled from both sides.

- Install the door structures on the hinges. Lightweight fiberboard door allows you to carry out events on your own.

- Stamp the seams, thereby eliminating the voids between the wall surface and the box. Complete solidification is carried out within 24 hours at room temperature.

- Carry out finishing work. Determining the type of finish will help create an optimal design.

For a visual demonstration of the installation process, see the following video.

How to install fittings?

Experts do not recommend independently carrying out work on the installation of the door structure, replacing the lock and arranging the thresholds, since these activities require high professionalism. Experienced craftsmen will help you purchase a set of high-strength materials, determine the order of work, install the structure correctly, insert the door frame into the opening. It is possible to assemble the structure, ensuring a high quality of assembly, with the help of special devices.

It is necessary to insert fittings elements using modern technologies and installation methods during preliminary measurements using a tape measure or ruler. High quality hardware is used as fasteners. At the initial stage, a scheme of work is formed, a set of necessary tools is made, the box is inserted into the opening, and hidden hinges are installed.

Successful examples and options

Before starting the door installation activities, you need to familiarize yourself with good examples and design options. On the websites of companies engaged in licensed activities, samples of doors in a Khrushchev building, a modern apartment, and an equipped kitchen are presented. At the same time, it is important to pay attention to a high-quality installation, made in accordance with technical requirements: holes are carefully made in the wall, structural parts are inserted at the required angle.

Reviews of experts

Experienced craftsmen appreciate the advantages of installing structures from natural materials. Such doors are distinguished by their high practicality and impeccable aesthetic properties. The beauty of natural wood can serve as a decorative element in the design of a living room, bedroom or children's room.

Error correction tips

On the site of well-known companies offering door construction services, tips for correcting errors are presented. Users, as a rule, are interested in the questions of what to do if the box is installed obliquely, how to redo the slopes. Experts comment on the problem posed regarding how to seal the cracks or what is the plan of action after the installation of the structure. Practicing masters will tell you what to look for and how to check if the door blocks are installed correctly.

Next, watch a video about 10 common mistakes when installing interior doors.

The comment was sent successfully.