Overview of the physical properties of wood

Everyone is well aware of the fact that wood is one of the highest quality, reliable, durable, wear-resistant, beautiful and environmentally friendly and safe building materials. Today, various types of trees, as well as many years ago, are used to make all kinds of structures, furniture, small interior details and much more.

In this article, we will tell you in detail about the physical properties of wood - what factors they depend on and how they change over time under various influences.

Features of appearance

Wood type is one of the physical properties of a material, which is determined by gloss, texture, color and macrostructure.

One of the most important characteristics is color. There are many options for the color of wood, it all depends on the species. Some of them have such a distinct color that they are recognized precisely by it.

Also, do not forget that the color of even sawn wood can change. It all depends on whether the material is exposed to water, snow, wind, light and various microorganisms.

The surface of the wood can display the luminous flux. This property is called brilliance. The most brilliant types of wood are beech, oak, acacia.

If you cut down a tree, cut its heart-shaped rays, vessels and annual layers, then a beautiful and unique pattern can be observed on the surface, which is called the texture and macro-texture of wood. This property of wood is very much appreciated. For example, when choosing a material for the manufacture of expensive and exclusive furniture, they first of all look at the texture of the wood. At the same time, the width of the annual layers is determined, which make it possible to understand how old it is.

Each of the above properties of the appearance of wood, depending on the species, is certainly very important., but, as already mentioned, under the influence of various environmental factors, they can change.

All about humidity

Moisture is one of the most important factors, characteristics of the material, with which you can determine the amount of water contained in wood. There is water in absolutely every tree, as it is necessary for the functioning and growth. But when it comes to felled wood, the use of which is planned in production, the amount of moisture in the material should be minimal.

The moisture content of wood is measured as a percentage and is determined by the ratio of the mass of water that is in the material to the mass of dry wood. It is currently being determined in laboratory conditions.

In practice, two methods are used to calculate the moisture index.

- Straight. This is a rather lengthy process. The method involves long-term drying, during which all the water is released from the material.

- Indirect. This method is more often used in practice to determine the moisture index, since it is simpler and takes little time. In the process of determining the amount of moisture in an indirect way, a special device is used - a conductometric electric moisture meter. Using this device, you can determine the value of the electrical conductivity of the material.

It should be noted that the direct method, although time consuming, gives more accurate results, but the indirect method has an error that can reach 30%. It was experimentally found that wood that can be used in the production process should have a moisture content of no more than 12%.

There is a certain classification of wood depending on the degree of its moisture content.

- Wet. Such material is characterized by 100% moisture. Most often it is wood that has been under water for a long time.

- Freshly cut. The moisture content of such a material varies from 50% to 100%.

- Air dry. This is a felled tree that has been drying in the open air for some time. The percentage of moisture is 15-20%.

- Room-dry. The moisture content of such material does not exceed 12%.

- Completely dry. Material that has already been processed and dried in a special chamber at a temperature of 103 ° C.

What other properties are physical?

Today wood is one of the most demanded materials. That is why the physical properties of wood as a structural material are, of course, significant. This is because they affect the performance and performance of prefabricated timber structures. In addition to the above qualities, such as appearance and moisture, there are others.

Shrinkage

In the process, when cohesive water is removed from the material, the volume decreases and the linear dimensions of the wood change. The result of maximum shrinkage, when all the water is removed, is a visual change and the appearance of cracks both internally and externally.

Warping

When the material during processing (it can be sawing, planing, rib division) changes its original shape, the warping process takes place. It manifests itself in the process of shrinkage, it is longitudinal and transverse.

Swelling

The volume and linear dimensions of wood are not constant indicators, they can change over time under the influence of various environmental factors. One of these factors is the increase in the volume of cohesive water in the material. Open air, in which there is moisture, increases the amount of cohesive water.

This property is considered negative when it comes to designing, for example, furniture. But if you need to build a ship or design a barrel for storing wine, such a property as swelling is very appropriate. It provides a tight connection of all structural elements.

Moisture absorption

One of the negative characteristics of wood, regardless of the type and species, is moisture absorption. This property is typical for all tree species. That is why absolutely all structures made of wood are subject to processing with special means before entering the consumer market. Their surface is covered with a film and paint and varnish material, which prevents the material from absorbing moisture.

Density

Density is the mass per unit volume of a material. The indicator is measured in kg / m³ or g / cm. In the production process, the basic density is taken as the main indicator. To determine it, two quantities are used - the mass of a dry sample and its volume in a wet state. The ratio of these two values is derived and the basis wood density is obtained.

The density of wood is low - moisture index from 540 kg / m³, medium - density from 550 kg / m³ to 740 kg / m³ and high.

High density wood has a value of more than 740 kg / m³.

Permeability

The permeability of a material is its permeability. In laboratory conditions, it is determined how and in what quantity the material passes gas and liquid supplied under high pressure.

Thermal

The thermal properties of a material include indicators such as specific heat, thermal conductivity and thermal expansion.The first indicator determines the ability of raw materials to store heat. Using special methods, set the amount of heat that is necessary in order to heat 1 kg of material by 1 ° C.

With the help of the second indicator, you can determine the rate at which heat is transferred in the material. But in the process of thermal expansion, one can observe a change in volume and linear dimensions.

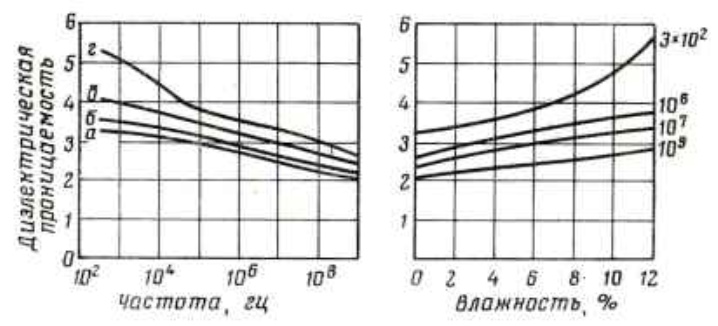

Electrical conductivity

This property determines how much the material conducts current. The higher the moisture content of the material, the level of cohesive water, the lower the resistance to current.

Electrical strength

This property is determined in the event that the raw material will be further used as an electrical insulating material. This indicator is influenced by the species of wood, humidity, temperature.

The higher the temperature and humidity, the lower the dielectric strength of the material, and vice versa.

Sound conductivity

Wood is a material that is capable of transmitting sound. There are three levels of sound transmission in lumber. The lowest level is found in tangential fibers, medium - in radial fibers, and the highest sound conductivity is located along the fibers. That is why this material is so often used to make musical instruments.

Dielectric

An alternating electric field is used to determine this property. It was found that when a mechanical force acts on wood, electrical charges appear on its surface.

The comment was sent successfully.