Sizes of boards

Among all lumber, boards are considered the most versatile. They are used in a variety of applications, from furniture manufacturing, construction and house cladding to the construction of trailers, wagons, ships and other wooden transport structures. The types of boards and their sizes are very variable, so you need to understand in which case lumber with certain characteristics is used.

Standard sizes of boards of different species

The technical parameters of the boards are selected taking into account the nature of the work. The choice is usually influenced by the position of the lumber, the magnitude of the load, as well as the possibility of exposure to various unfavorable factors. These features determine not only the dimensions of wooden products, but also their type and type of wood.

Today, there are a large number of regulations and standards for determining the size of any lumber. Licensed logging and woodworking enterprises operate according to their requirements, therefore, the dimensions of various types of boards are strictly fixed.

According to GOST, a board is called lumber, the thickness of which is no more than 100 mm, while the width is twice or more than the thickness.

The dimensions of a standard edged board are defined as the minimum distance between its six opposite surfaces. Unedged type of sawn timber is an exception, which will be discussed below.

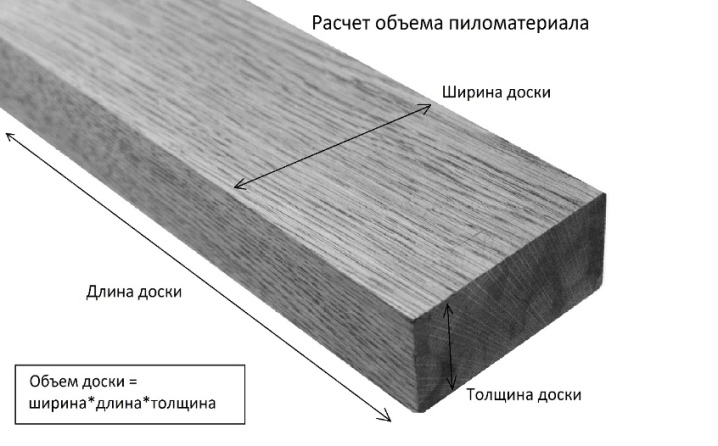

Geometrically, a edged board is a typical parallelepiped. The widest surfaces are called flats, and the thickness or height of the lumber is determined between them. The adjacent sides on the sides are represented by long edges, on which the width of the board depends. The cross-sectional surfaces on opposite sides are the ends used to define the length.

Let's take a look at the correct way to determine the dimensions.

-

Length. The parameter is measured in meters (m) as the smallest distance between opposite ends of the workpiece. Particular attention is paid to the length of decorative boards that go to the outer and inner cladding of the building. In other cases - the manufacture of furniture, the construction of hidden and temporary building structures - the parameter can be neglected.

-

Width. The parameter is measured in millimeters (mm). For edged boards, it is defined as the smallest distance between the edges at any place of the workpiece at a distance of 150 mm from the ends. For unedged ones - in the middle part of the workpiece as a half-sum of the widths of the upper and lower layers, excluding bark and bast.

-

Thickness. The parameter is measured in millimeters (mm) between the faces in any part of the workpiece, but not closer than 150 mm from the edge of the end face. Together with the width, it makes up the cross-sectional dimensions of the product. Both parameters allow slight deviations in accordance with GOST.

The standard sizes of boards of different species may vary slightly.

Conifers

Typical representatives are larch, pine, spruce, fir and cedar. The first two belong to light conifers, the rest - to dark conifers. Less common among the entire assortment are juniper, yew, thuja and cypress.

Sizes of softwood lumber are determined by the GOST 24454-80 standard. Its requirements apply to all types of boards used for government industry and domestic trade. The standard complies with many European regulations on the dimensions of sawn timber, which makes it possible to export and import them on the world market.

The working length of coniferous boards varies over a wide range. The minimum value is 0.5 m, the maximum is 6.5. Intermediate values are in increments of 0.1-0.25 m.

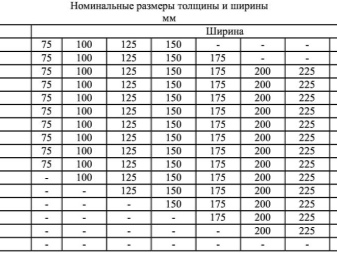

The width of the coniferous planks is presented in the range from 75 to 275 mm in increments of 25 mm. The thickness, in turn, is 16-100 mm, and boards up to 35 mm thick are considered thin, and from 36 to 100 mm thick.

The size ratio is usually determined according to the table from GOST. The most commonly used boards are from 3 to 4 meters long with an aspect ratio in the section of 30x150 mm or 150x20 mm, where the smaller number indicates the thickness.

Deciduous

The wood of this group is more diverse than that of conifers. Among them, there are hard and soft-leaved species. Typical representatives of the first group are oak, beech, hornbeam, ash, and the second - aspen, alder, poplar, linden, willow.

Dimensions are determined in accordance with GOST 2695-83. The length of hard-leaved species ranges from 0.5 to 6.5 m, and of soft-leaved species - from 0.5 to 2.5 m. In width, edged boards are made from 60 to 200 mm with a step of 10-30 mm, unedged and one-sided edged boards are made from 50 to 200 mm with a step of 10 mm. The thickness of all types varies from 19 to 100 mm.

Please note that it is possible to produce sawn timber from soft-leaved species with coniferous sizes in accordance with GOST 24454-80.

The dimensions of the boards are determined using special measuring devices - long metal rulers and calipers. For the same purpose, manufacturers often use various templates or calibration blanks, the error of which is minimized. Measurements are made several times at regular intervals.

Deviations from the declared parameters are allowed, the maximum permissible values of which are determined by GOST. For softwood and hardwood, they are identical and are measured in mm.

By lenght:

-

+50 and -25.

Width:

-

up to 100 mm ± 2.0;

-

100 mm or more ± 3.0.

By thickness:

-

up to 32 mm ± 1.0;

-

32 mm or more ± 2.0.

The listed dimensions and their permissible deviations apply only to products with a moisture content of 20%. When drying out, the dimensions of the wood can be significantly reduced, therefore, the dimensions of boards with more or less moisture should be multiplied by the appropriate coefficient, the value of which is determined in accordance with GOST 6782.1.

When the wood is completely dry before packing and shipment, it requires control measurements.

Consider examples of marking a finished batch of boards.

-

Board - 1 - spruce - 30x150x3000 GOST 24454-80

Explanation: board of the first grade, spruce, with an aspect ratio of 30 to 150 to 3000, made in accordance with GOST 24454-80.

-

Board - 3 - birch - 50x150x3000 GOST 2695-83

Explanation: a board of the third grade, birch, with an aspect ratio of 50 to 150 to 3000, made in accordance with GOST 2695-83.

Types and their dimensions

In construction, 2 types of boards are used: edged and unedged. The former differ from the latter by full processing, fixed dimensions with a strict aspect ratio, and their edges can be either parallel or non-parallel. Edged boards are produced, as a rule, planed. That is why the requirements of GOSTs allow for deviations: during processing and subsequent grinding, 1-2 mm can be removed.

The dimensions are selected taking into account the nature of the construction work. The most acceptable aspect ratios are considered: 30x150x3000 mm, 20x150x3000 mm, as well as their 4-meter counterparts. Please note that the manufacturer has the right to produce lumber of non-standard sizes at the request of the customer.

Sometimes construction requires longer lumber. They are used to avoid unpleasant joints, for example, when decorating a building from the outside, building roofs, stairs.

Then boards with the same aspect ratio in section and increased length are used: 30x150x6000 mm, 20x150x6000 mm.

Unedged boards, in turn, are characterized by a rougher processing, and only lumber layers are subjected to it, bast and sometimes bark remain on the edges. Separate requirements are established for them. For unedged sawn timber, as well as for edged timber with non-parallel edges, the width of the narrow part must be at least 100 mm for boards up to 50 mm thick and at least 200 mm for boards with a thickness of 60 to 100 mm.

Both types, depending on the method and duration of storage, can be dry or with preserved natural moisture. This is also worth considering when buying, since the latter dry out over time and partially decrease in size.

The nuances of choosing the size of lumber

In construction, boards are used for a variety of purposes. Some owners use them for the construction of a frame house, others only for wall cladding and flooring, and still others use them to equip a roof. You can determine the required dimensions of wood materials according to the drawings. The recommendations below will help you understand the basic requirements that apply to lumber for various construction work.

Foundation

In this case, the boards are used in the manufacture of formwork for the blind area, less often for strapping the pile foundation, which significantly increases the strength and reliability of the structure, saves on materials.

Boards are usually used in conjunction with a bar and stacked on it in the second row.

The length of the material must fully correspond to the dimensions of the foundation. The optimal width is 20-25 cm for a double-row strapping and 40 cm for a single-row strapping, the thickness is 5-8 cm.

Frame

Of the tree species, spruce and pine are best suited for the construction of the frame. In this case, boards of the first or second grade are used. You can use boards with defects, since they will not be visible, but before use, it is imperative to treat them with protective solutions against fungus and insects. The length of the frame planks must correspond to the dimensions of the structure in order to avoid unwanted joints. The width of the vertical and horizontal racks should be 20-30 cm, and the thickness should be at least 4 cm.

Walls and ceilings

The internal walls of the room are subjected to significantly less loads than the foundation and frame of the building, therefore boards with dimensions in the cross section of 10-15 x 2.5-5 cm are suitable for such purposes. Overlappings between floors require more durable materials, so boards up to 20-25 cm wide and about 4-5 cm thick are well suited.

Roof

The materials used for the construction of the roof must meet several requirements. The rafters and lathing of the roof must be strong, ensure the reliability of the structure and at the same time not create an increased load on the building frame and foundation. It is recommended to use well-planed and dried boards with a thickness of about 4-5 cm and a width of about 10-13 cm.

Cladding

Upon completion of the construction of the main elements of the building, you can proceed to interior and exterior decoration.

Today the market of facing decorative sawn timber is represented by a fairly wide assortment: lining, imitation of a bar, block house, planken, parquet board.

They differ in relatively small transverse dimensions, since they perform an exclusively aesthetic function.

Facade boards

Facade boards additionally provide the function of heat, sound and vapor insulation, therefore they are made in a wider format. Finnish boards are considered the best option for cladding, since they are less prone to deformation and cracking, as well as high strength.

Doors and windows

Products for the arrangement of door and window openings include platbands, and additional boards are also used. The dimensions are selected taking into account the dimensions of the passage and, as a rule, are standardized by the manufacturers. Typical dimensions of expansion strips are 10-15 x 100-150 x 2350-2500 mm.

The variability in lumber sizes is quite wide. Nevertheless, choosing the right dimensions is not as difficult as it might seem at first glance. There are two simple rules to remember.

The cross-sectional dimensions increase in proportion to the load on the timber structure, which implies the use of thicker and wider materials in the construction of load-bearing and supporting elements.

Avoid lengthwise unwanted joints between the boards to avoid possible penetration of moisture with mold and increase the reliability of the structure.

Calculate the size of the lumber in advance before purchasing them in order to accurately determine the required volume of production and use it without residue.

The comment was sent successfully.