How to splice two boards?

Typically, different timber products have specific dimensions, but in construction sometimes a non-standard width or length is needed. That is why there are various connection options that will allow you to make the necessary board or block. In this case, cuts are used, which can be done by hand or with the help of special equipment.

Basic ways

In carpentry or construction, two boards often have to be spliced together. Quite often, a connection is necessary when there are several short segments and one of them must be made up with a specific length. Of course, this method cannot be used for all products. For example, gluing is appropriate if the door leaf or rafters are being made, but the component parts are not suitable for the floor or benches.

During the work with wood, a person learned to fasten boards together in a variety of ways. For example, it will not be difficult for an experienced carpenter to make one out of three. It is important to know that the fewer pieces used in the splicing process, the more durable the final product will be. You should also take boards for joining along the length with the same width. In order to better understand how to qualitatively connect the boards to each other, it is worth considering each of the methods in more detail.

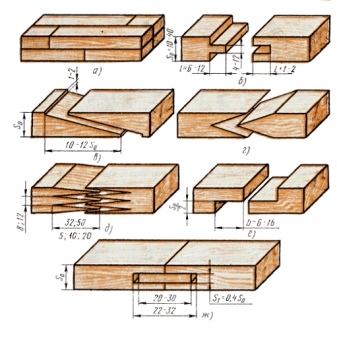

By width

Timber of small width is fastened together to obtain a shield of a certain size. To do this, you can use various docking methods.

- On a puffer... With such a joint, the boards are called plots, and the resulting seam is called a jointer. A good jointing is obtained only if there are not the slightest gaps between adjacent boards.

- On the rail. The essence of the method is that at the edges of the board you need to select the grooves into which the slats will enter. It is with the help of the latter that the plots will be connected to each other. The thickness of the strip and the groove itself should be one third of the thickness of the material that will be fastened.

- At a quarter. In the plots to be joined, quarters must be selected along their entire length. It is important that ¼ is not more than half the thickness of the boards themselves.

- In the groove and ridge (in the rib). With such a docking, a groove is made from one edge of the board, and a ridge is made on the other. The shape of the connecting elements can be triangular or rectangular. It is worth noting that triangles provide less strength. Of course, rectangular ridges and grooves are less economical in terms of material consumption, but they are convenient to use in various places.

- "Dovetail". The docking principle is the same as in the previous method. The main difference is in the form of a trapezoidal ridge, reminiscent of a swallow's tail. This method often uses dowels.

By lenght

When boards need to be joined so that the length is as long as possible, a number of methods are used.

- Closely.

- Into groove and comb implies that a recess will be made on one side of the board, and a protrusion of a suitable size on the other.

- On a mustache - is a very difficult method as it requires precision. It is assumed that the edges of the board are cut so that an inclined plane is obtained.

- Serrated adhesive bond is the most robust type. It is carried out in the form of two or more teeth on one board and with corresponding slots on the other.

- At a quarter - fully corresponds to its name, when the ends of the board are cut lengthwise by 25%, and then connected to each other.

- On the rail - is done by cuts at the ends of the boards and inserting a small strip into them.

For splicing bars, there are also a number of options that are most popular.

- Half a tree - can be used if the length is at least 2 times the thickness of the bar. To increase reliability, you can use a wooden nail (dowel).

- Oblique cut - used with shortening of the ends. Pins are also used for fastening.

- Surface lock (straight or oblique) - good in structures in which there is a tensile force. If the type is straight, then the lock is placed immediately on the support, and with an oblique one - next to it.

- Tension lock (straight or oblique) - are distinguished by good durability. However, this method is tricky. It should be borne in mind that in the process of drying out the wood, the wedges will weaken. That is why you should not use this lock for structures with high loads.

- Back to back - implies that both ends of the board will be placed on a support and then fastened using staples.

Among the fastening of boards or logs in construction, for example, frame buildings, the following options can be distinguished.

- Half a tree - is a cut or cut of half the thickness at the edges of the boards, and then their connection at an angle of 90 degrees.

- Corner frying pan - similar to the previous method. The main difference is that one of the logs will be smaller in width compared to the other.

- Shipovoy.

- Half-handed - is done by cutting off inclined planes at the edges of the boards, which ensures a very tight joint. It is worth emphasizing that there is a separate formula for determining the angle of inclination.

Height

Bars are fastened crosswise in height most often when the construction of bridge structures is underway. The following types of connections are distinguished:

- in half a tree;

- 1/3 or 1/4;

- notch a bar.

When building boards in height, several types of fasteners are also distinguished:

- end-to-end with a secret spike;

- end-to-end with a through ridge;

- in half a tree with fastening with clamps;

- in half a tree with fastening with a strip of steel;

- oblique cut with fasteners in the form of clamps;

- close;

- fastening with bolts.

As a rule, joints make up 60-66% of the size of the thickness of the parts to be joined.

Spike fastening

For overlap, a connection with spikes and recesses is often used. You need to start this process by tracing the contour of the parts using the marking lines. In this case, it is important to make an indent from the end, which will be equal to the width of the bond. Lines should also mark the thorn itself on the backs of the boards and the end. Carefulness and accuracy must be shown so that the markings on the details coincide in all places.

A hacksaw is used to trim the spike. She makes a cut from the sides, and then the wood is removed with a chisel. It is worth making the spike a couple of millimeters larger in order to then more accurately process it with a chisel. To make a groove, a longitudinal cut is made, which is then finalized with a chisel. It is also important to leave a few millimeters of machining allowance here.

After that, fitting is performed. This process involves aligning the parts so that they fit as tightly as possible to each other.

There is a T-shaped bond, when the main spike is made on one of the boards, and an eyelet on the other. This method is good in that, when connected, the fastener will firmly enter into place and securely connect the parts.

Wide planks are perfectly spliced by the box method, when not one, but several spikes and grooves are made at once. The easiest way is to fasten the connection to the protrusions by drilling through and inserting a dowel of wood into the resulting hole.

End-to-end and right-angle mounting

When joining wooden parts end-to-end, it is important to maintain an angle of 90 degrees. This process does not involve an overlap or groove connection. Butt fastening is not complete without the use of screws, nails and other fasteners. They are necessary to securely fix all parts. In addition to fasteners, you will need a lot of other tools and materials:

- wood;

- workbench (preferably portable);

- hammer;

- putty;

- screwdriver;

- pencil;

- metal corners;

- glue for carpentry work;

- metal plates in the shape of the letters T and G, as well as in the form of a triangle.

When joining the boards end-to-end, the whole process can be divided into convenient stages.

- Fixing one of the boards on a workbench and overlaying the other on top of it so that the necessary elements are end-to-end. If necessary, you can make a markup.

- Fastening parts using nails or screws. In this case, it is important that the head of the fastening element is barely visible on the surface. To do this, you should use a putty. To prevent the wood from splitting, you can make holes under the nails and screws in advance. The use of metal corners makes the corner joints stronger.

To make the butt joints more durable, you can use one of the strengthening methods.

- T-piece suitable if you need to connect the boards in the form of the letter T. The essence of such a splicing is that flat plates lie in the center of the boards, in which holes are drilled, and then screws are screwed in. The fasteners are reliable, but highly visible.

- Metal corners allow you to create a frame at an angle of 90 degrees. It is important to attach such corners to both sides of the boards that are spliced.

For information on how to splice two boards, see the video below.

The comment was sent successfully.