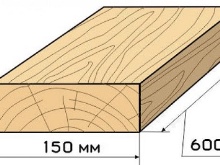

What are the boards 50x150x6000 mm and how many pieces are in a cube?

When carrying out various assembly, construction and finishing works, wooden materials are used. Boards of various sizes are in great demand. Today we will talk about these lumber 50x150x6000 millimeters.

Species overview

These timber structures are of various types. Let's consider some of the varieties separately.

- Edged. This type is often used when performing construction and finishing work, including when laying floors and roofs. Edged boards are called boards in which the edges are sawn at right angles to the faces. In this case, the edges can be both parallel and non-parallel. The permissible wane values should not exceed the norms established by the regulatory and technical base.

- Unedged. Such boards have uncut or only partially sawn edges. At the same time, sagging is more permissible in comparison with edged boards. Most often, lumber of this type is used when carrying out a variety of rough work. They belong to the 2nd grade. The products are distinguished by a lower cost, less attractive external design.

Also, a board of 50x150x6000 millimeters can be planed and non-planed. The first option is considered a higher grade material. It can be either dried or raw. Unshaved boards are extremely damp.

Planed lumber is made from edged boards by special additional processing. As a result, the finished products become absolutely smooth, their cross-sectional shape is precisely calibrated.

Boards also differ depending on what kind of wood they are made from.

- Pine. It is pine wood that is most often used in the production of these building materials. Boards made of this needles can boast of special resistance to mold, various insects, and decay. In addition, pine products have relatively high sound absorption and moisture resistance.

- Spruce. Lumber made from such a tree is also considered to be the most moisture resistant. During operation, they practically will not crack. But at the same time, spruce has a relatively low strength.

- Larch. This wood species is distinguished by a beautiful and interesting texture, a variety of shades. At the same time, larch has a low level of water absorption, good resistance to mold, fungi, insects, harmful microorganisms. The breed also boasts good fire resistance.

- Cedar. By its basic properties and characteristics, cedar is very similar to larch. It has good moisture resistance, fire resistance, decay resistance. The structure of the wood is quite pliable and soft. As a rule, planks made from cedar are used for finishing work. The base also has high thermal insulation and noise insulation performance.

- Birch. Birch boards are also often used when performing various finishing and construction works. They are distinguished by their durability and relatively low cost. At the same time, birch often cracks strongly and can be negatively affected by various biological factors.

- Aspen. Aspen boards are rarely used in the construction industry, although they have many important advantages. They practically do not crack. Such lumber is considered to be quite durable, resistant to decay processes, mold formation.

- Oak. Oak boards are distinguished by the longest service life. Such products have special strength, resistance to various unfavorable biological factors, but at the same time, oak lumber also has a very high cost, so they are not used so often in the construction industry.

- Linden. This wood is also rarely used for construction and finishing work. It is considered quite flexible, practically does not crack when properly processed. If necessary, the tree can be given almost any shape. But due to its excessive softness, linden cannot be used in the construction of load-bearing structures.

- Ash. This wood is valuable. Ash can be compared with oak in strength and durability. The tree practically does not absorb moisture. As a rule, such boards are used in the construction of terraces, verandas and balconies.

- Beech. Wood has increased density and hardness. Beech has a beautiful and rich structure, it gives the finished product a more aesthetic appearance. When steaming, beech boards will bend well.

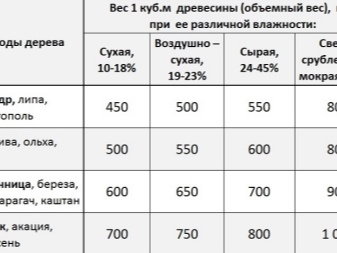

The weight

The weight of finished treated boards can vary significantly depending on whether they are wet or dry, from what kind of wood they are made. So, the weight of a pine edged board with a size of 50x150x6000 millimeters is 23.4 kilograms.

The weight of the unedged board will be slightly larger due to the increased amount of wane. The weight of the board can be easily calculated by yourself. There is a special formula for this: length x width x density x thickness.

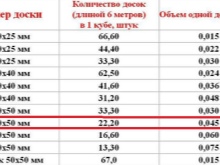

How many pieces are in 1 cube?

Before purchasing the necessary lumber, you should accurately calculate the volume, the amount of material in a cubic meter. It is important to calculate the area of the lumber. To determine this indicator, there is also a special formula: width x thickness x length. In this case, you need to take the numerical indicator 10 to the 6th power (a cubic meter is equal to 1,000,000 cubic meters / cm), we divide it by the number obtained by the formula. As a result, it turns out that there are 22.2 boards in one m3.

Applications

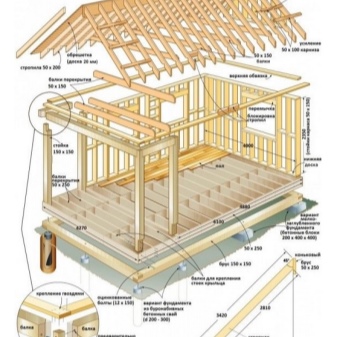

Boards measuring 50x150x6000 mm are often used in frame construction. These materials can be used to build walls in houses. They are also often used for the construction of internal partitions. For the implementation of rafters, such boards will also be suitable. At the same time, the created structural elements will have maximum strength. When using reliable fasteners, the structures will be able to withstand any roofing.

Treated lumber 50 by 150 millimeters will help make a high-quality and strong floor. Moreover, it can serve as the main topcoat, and as a base for laminate or parquet, linoleum. In the furniture industry, such materials are also widely used.

Boards, which during the manufacturing process undergo chamber drying and careful special processing, are used to create cabinet furniture. Sometimes similar materials are used in the production of containers.

The comment was sent successfully.