Supports for the jack: types, characteristics and selection

Anyone knows what a jack is. This is a special tool with which you can organize the implementation of various do-it-yourself vehicle repair work. However, not everyone has an idea that the jack is equipped with supports.

Support for the jack - a structure with the help of which it is possible to increase the area of the supporting surface and increase the stability of the DU and DG units, the carrying capacity of which reaches 50 tons.

With jack pads it turns out to expand the scope of devices used for repair. It is worth taking a closer look at what supports exist and how to use them correctly.

Views

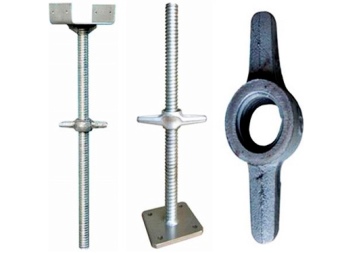

There are two main types of jack supports. it screw and rubber models. With their help, the operation of the unit becomes safer due to the fact that the elements provide the stability of the structure. This allows us to expand the range of work performed and make them more reliable and of high quality.

Regardless of the type of support or cushion, they have high performance strength, long service life and ease of use.

Let's take a closer look at each of the types.

Rubber

These are the most common coasters (heels). They are available in most parts and parts stores and have a wide range of products. The rubber lining is marked with the letter K. For the manufacture of the structure of the thrust bearing, the support is used cord, which significantly extends the service life of the product. The advantage of rubber pads is their low price, which makes parts for the jack affordable.

The production of high-quality rubber supports is carried out by such companies as:

- AE&T (China);

- Nussbaum (Germany);

- OMA-Werther (Italy);

- Ravaglioli (Italy);

- Sivik (Russia);

- DARZ CJSC (Russia);

- OJSC "Avtospesoborudovanie" (Pskov, Russia);

- JSC FORMZ (Russia);

- Serpukhov (Russia).

And this is not a complete list of popular manufacturers of accessories for car lifts. Not so long ago, there were also slotted models suitable for bottle jacks.

Screw

Screw feet are an integral part of jacks used to adjust wooden support posts... With their help, it is possible to adjust the height of the structures, which is very convenient in wooden housing construction. For the convenience of work, use adapters.

Also, nozzles with screw supports are used in low-rise constructionwhere wooden structures are used. The units do an excellent job with the assigned tasks, ensure reliable performance of work, and also have improved strength characteristics and increased lifting capacity.

Marking and manufacturing

The next thing to consider in order to know better about jack supports is the designation of the main characteristics. The following types of markings are accepted in such accessories:

- outer diameter - A;

- landing diameter - B;

- the height of the penny seat - h;

- product height - H.

All indicators are measured in millimeters... Each model has its own specifications, therefore, it is recommended to pay attention to them in order to choose the right pad for the jack correctly.

For the manufacture of supports, high-impact plastic or metal is used that can withstand high loads.

The design includes a spacer and stiffeners and spacers. This increases the resistance of the product to deformations and external influences, and also prevents friction of the elements. Additionally, some models are equipped with a corrugated support surface and a washer. This prevents the support from moving while the jack is in operation.

Application

Jack supports are widespread. They are used in the following situations.

- On loose and clayey soils, as well as in difficult terrain, where it is necessary to ensure the stability of the jack during operation by increasing the surface area of the support.

- In cases where the car is bogged down. These are mainly rubber bearings. Before starting work, the pads are installed under the jack so that it is convenient to support the unit.

- To improve the safety of the process. In this case, the supports are not used for the stability of the jack, but are simply placed under the wheels of the car.

Regardless of the method of application, it is important to remember that lifting by means of special pads must be carried out smoothly so that the structure does not collapse.

Choice

Buying a suitable jack support is a big deal. When choosing, it is recommended to pay attention to:

- key characteristics;

- manufacturer;

- type of lining;

- price;

- carrying capacity.

Taking these factors into account will help you choose the right product for comfortable construction or repair work.

For information on how to make a rubber support for a jack, see the video below.

The comment was sent successfully.