All about High Jack rack and pinion jacks

There are times when it becomes necessary to lift some load to a height of about 1 m. For example, it may be a car that has fallen into a ditch. An ordinary jack is indispensable here. In this case, the High Jack rack jack can help us. But the scope of its application does not end there. In today's article we will analyze what kind of jack it is, its features and find out how to use it correctly.

Peculiarities

The rack and pinion jack has a simple design. It consists of:

- guide rail along its entire length (which depends on the model of the jack itself);

- round holes are located at an equal distance;

- handles, when pressed, the carriage and the support platform itself, on which the entire load rests, moves.

This site can be very low above ground level. Some models allow you to start lifting from 10 cm. The weight of the lifted load can be from 2 to 20 tons, depending on the model and device.

Moreover, for a jack of the described type there is no difference in which position to work - it pulls equally both in a vertical position and in a horizontal position.

Each of the devices has its own transmission:

- Single stage models can lift weights up to 6 tons.

- If the model is two-stage, then the weight can be up to 15 tons.

- The three-stage models are capable of handling loads of up to 20 tons.

The principle of operation of such a mechanism is based on the interaction of the rack and the ratchet mechanism. To lift the load, the lever is forced downward. At this moment, the carriage is rearranged exactly 1 tooth along the toothed rack. To continue lifting, you need to raise the handle again to its original position at the highest point and lower the lever again. The carriage will jump 1 tooth again.

You can see the High Jack rack jack in action in the next video.

All moving elements are protected by a casing to protect the mechanism from dirt getting into it, although the entire system may well be washed out in the nearest reservoir. Some owners of such devices lubricate all moving parts with oils. This is not the best solution for such a device. Since the oil, or to be more precise, its film collects all the dust it can, and as a result, the accumulated dirt complicates the operation of the entire mechanism. At the same time, such a substance cannot be easily washed off with water.

This type of jack is best kept clean and dry.

The described jacks are favorite accessories and indispensable helpers for off-road enthusiasts. Every self-respecting lover of such a vacation must attach a rack jack to his car. With its help, it is possible to pull out a multi-ton jeep with full marching equipment inside, which is firmly entrenched in a ditch or rut. The robust design and large dimensions make it possible to use the jack as an anchor, if necessary, in order to extract the machine with an electric winch. To do this, on an area where there are no trees, but there are various boulders, the jack is fixed between them, the car clings to it.

It is fair to say that the rail is not designed for such loads, therefore, after some such events, you can see a bent rack jack. There were times when they managed to bend it 90 degrees.

Like any tool that sooner or later has to be used, these jacks have their own undeniable advantages:

- Simplicity of design and use. This type of lifting mechanism is very reliable and unpretentious in use. The seemingly weak structure is capable of withstanding serious loads.

- High lifting height allows you to pull out a deeply stuck machine.

- Fast operation of the mechanism. You can lift the load to the desired height in a matter of minutes.

Of course, such a tool will not do without its drawbacks, which are worth noting:

- Very large size. Some models exceed the length of 1.5 m, so a place for such a necessary device is not found in every car, but only in large SUVs.

- The small support area of the jack itself forces you to carry with you the so-called "shoe". This is a support platform that increases the area of contact with the ground so that the device does not sink into the ground under the weight of the machine.

- Not suitable for all types of cars. The specificity of the hitching to the car implies the presence of power elements of the body, which are abundant in prepared jeeps (power bumpers, thresholds, various lugs), all this is not available in a conventional car and it will not work to hook a jack on a plastic bumper to replace a wheel.

The most important rule when working with such a jack is safety.... This moment got into disadvantages for a reason. A car raised on such a jack is extremely unstable, therefore, it is categorically, under no circumstances to climb under it. In addition, very often the car breaks off the jack, in this regard, there is such a thing as a "hijack fall zone", falling into which is life-threatening.

If the car falls, and the jack is in a clamped state, then its handle begins to jump with great speed and, most importantly, force. It is impossible to stop it with your hands, and most injuries (knocked out teeth, broken jaws, broken ribs and limbs) occur at this very moment.

If this happens, let the mechanism dump the unnecessary load on its own, and it will stop by itself.

Top Models

Among the rack jacks, it is worth highlighting the most popular and high-quality models.

- "AUTODELO". Rack jack used for lifting vehicles and moving various loads. The operation of the stepper mechanism begins with a load of 50 kg. The most affordable jack of all the top budget models.

- Farm Jack FJ150. Manufactured in the USA. It has a wide range of applications, which includes clamping, pushing and pulling various weights. This model has a rail height of 150 cm, a maximum load capacity of 3 tons. The described model has a wide range of additional accessories.

- Magnus-Profi (Czech Republic). This Hi-Lift rack jack is made entirely of high quality steel. Its height is 1520 mm. The weight of the entire unit is 12.5 kg. A high quality jack designed for small and tall machines.

How to use

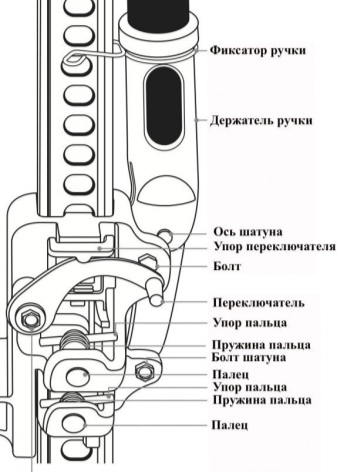

The described type of jack does not have many moving parts. Among them are a movable carriage, on which a lever is located, and a direction switching mechanism. There are only 2 of them: up and down. The mechanism itself is quite tight and switches not with a smooth interference, but with a sharp blow of the hand.

When the mechanism is in the down position and the handle is fixed, the carriage moves freely along the entire rail. If the mechanism is set to the up position, then the carriage works according to the principle of a reverse key and moves with a characteristic crackling only up the rail. This is necessary in order to quickly prepare the jack for work.

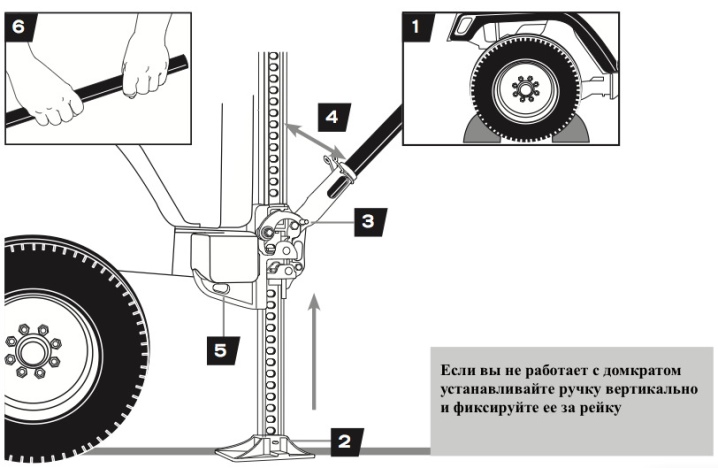

Before lifting, the jack must be at the correct angle in relation to the machine. It cannot be placed strictly perpendicular to the ground if a rise to a great height is required. As the machine is raised, the jack will tend to tilt towards the machine and may slip out and damage the vehicle. Therefore, the jack must be tilted slightly in the opposite direction from the machine. When you're done lifting, be sure to fold down the handle.

To lower the machine, you need to switch the directional mechanism to the lowering position, the handle must be fixed parallel to the rail. At this moment, all the most interesting and dangerous happens. As you lift the machine, you will gradually increase the force applied to the handle. At the moment of lowering, everything happens exactly the opposite. When the lever is at a 90 degree angle to the rail and the mechanism flips 1 hole, the lever releases energy in reverse order (from higher to lower). That is, at this moment you need to be as careful as possible and ready for the possible jump of the handle out of your hand.

While working, remember that such a jack is a thing with which you need to be able to work in order to maintain your health. You cannot hold on to the rail with an "open grip" with your free hand, that is, so that your thumb is in the path of the bounced handle. The return force of the handle is directly proportional to the load on the heel of the jack.

If the right hand slides off the handle while pressing, it will hit the rail by inertia. If there is a thumb in its path, then there is a high probability of not just a fracture, but complete crushing of the bone. The same goes for the operator's head. It is inadmissible to find the head on the trajectory of the handle bounce.

Review overview

The opinions of buyers about this modern equipment are very different, but most often users are satisfied with the purchased product, because it is quite specific - its area of application implies certain conditions and human skills that not every motorist possesses. The possibility of repair and common spare parts allow you to use the product for a very long time.

Parts subject to rapid wear are very easy to change. These are the factors that pleasantly surprised many users who decided to use these types of jacks.

Marked by buyers and impressive appearance. When such a "monster" is placed on the spare wheel or on the upper trunk, the car takes on the appearance of an all-terrain vehicle prepared for expeditions, even if there are very few other attachments. The operation of such devices can be dangerous if not properly acted upon.... This fact scares off some users who are little familiar with these jacks.

A more detailed and visual overview of the operation of High Jack rack jacks is presented in the following video.

The comment was sent successfully.