What is the tongue and groove and where is it used?

Not all people know what it is - a tongue-and-groove, what it is, and where it is applied. Meanwhile, metal and wooden sheet piles are used very widely in construction. It will definitely be necessary to deal with grooved VDSP and PShS, with composite groove and other types, with performing calculations in general.

What it is?

The term sheet piling in construction is usually meant to mean elements of a solid fencing. They are oblong and have tongue / groove locks on both sides. It is these connecting parts that facilitate the device from separate parts of an integral structure. Various materials are used for the manufacture of sheet piles. The choice is predictably determined by the load and the expected conditions of use.

In most cases, steel structures are used on construction sites. Unlike wooden or concrete piles, they are reusable. As a result, the costs of purchasing them in the long run are limited. The production of sheet piles has already begun in large volumes. They may look different, but design considerations are always taken into account for reliability and sustainability.

Types and their characteristics

Metallic

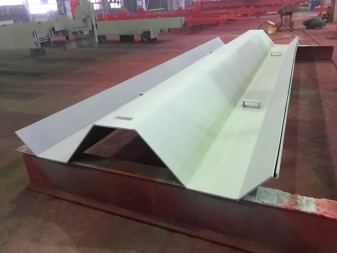

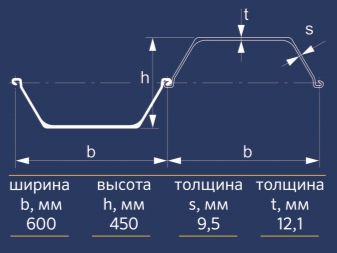

Almost always, we are not talking about an abstract metal, but about a concrete steel structure. Among them, the most widespread are Larsen dowels... Outwardly, such products resemble a trough-shaped profile. Their length can be up to 35 m, and their width is up to 0.8 m. Along with the modifications L4 and L5, Larsen sheet piles L-5UM and Omega are also in demand.

For such products, it is preferable to use premium steel. The addition of copper helps protect the metal from early corrosion. The L5 variety has the best technical characteristics. St3Kp or 16HG steel is used to manufacture such products. The standard strength level reaches 800 kilonewtons per 1 m.

Reinforced concrete

The length of such piles reaches 16 m. They have a large mass and are not always convenient. Fences can be made with driven or bored piles. The disadvantage of reinforced concrete sheet piles is that they are non-retrievable structures.

More precisely, you can extract them, but you won't be able to reuse them.

Wooden

Protective fences made of wood have been used for quite some time. But their role is steadily declining. More resistant and reliable materials are being replaced. Like concrete, wooden dowels cannot be removed. Their permanent or temporary use is allowed. It should be noted that the best species is larch.... Despite the high weight of 1 meter, it is particularly resistant to soil conditions.

Plastic

The use of composite materials in the arrangement of sheet piles is only gaining momentum. However, plastic products in the narrow sense must be distinguished from them. If a composite is close to metal in terms of its bearing capacity, then plastic cannot boast of such a property. It has another advantage - such a design weighs much less than a metal barrier of comparable dimensions. The cost of synthetic material is another powerful argument in its favor.

In addition, such products:

- easily transported over long distances;

- installed in a short time;

- serve for a long time (since they do not suffer from corrosion).

The term VDSB has no direct relation to those grooves that are introduced into the ground. It stands for waterproof tongue-and-groove chipboard. PShS, or sheet pile welded panel, is a completely different matter. This is the name used to sell ready-made steel assemblies created by welding. They are equipped with crane carrying loops, which greatly simplifies installation.

The metal consumption of PShS is noticeably lower than that of analogues. Sizes are very diverse, which allows you to choose the right solution flexibly. Thanks to the corner fittings, it will be possible to protect the pits of a complex configuration. The SShK sheet pile (decoding - trough welded sheet pile) is also widely used. It is worth considering that Both SShK and PShS are positioned by manufacturers as Russian analogues of Larsen sheet piles... In terms of turnover, they are at least no worse, and fully comply with the domestic GOST.

The standard describes:

- execution;

- basic structures;

- technical provisions;

- safety standards;

- limit deviations;

- welding methods.

Applications

In most cases, sheet piles are taken to build prefabricated walls or large partitions. For a pit for large buildings, such elements are strictly required. They help:

- avoid land collapse;

- exclude soil water seepage;

- prevent the destruction of neighboring buildings during construction work.

Often, tongue-and-groove piles are used to organize the strengthening of the coast (slopes) near embankments, port buildings, and reservoirs. They are also important for hydraulic engineering works during repair and construction:

- dams;

- dams;

- embankments;

- separate gateways;

- berths and marinas.

The scope of application of sheet piles, of course, does not end there. With their help, the walls of the tunnels are equipped. Going down into an underground passage or driving into an underground parking lot, hardly many people realize that such structures are hidden behind the walls. Not a single sewage treatment plant can do without a tongue, again. And even in landfill fencing, they are widely used.

When arranging stairs, sheet piling elements are again mounted under the steps. They connect the blocks to the support legs. The grooves for installation are prepared in advance, such products are fundamentally different from those that are driven into the ground.

With proper use, they will ensure the connection of the timber for a long time, and will work stably. And when building ceilings in houses, they use boards with tongue-and-groove parts of a special type, and they also show themselves from the best side.

In this case, it is meant only a protrusion that runs along the entire edge of the lumber. When it comes into contact with a similar part on another board, it “locks into the lock”. In any case, everything should be calculated very carefully. And also it is worth considering the features of a particular ceiling and the type of material.

Only trained professionals will be able to correctly perform such work.

Payment

It is also worth involving specialists in calculations. Trying to produce them yourself is unlikely to give a good result. Moreover, when contacting specialists, it is necessary to find out whether they have licenses (permits) for such work. When calculating, you need to determine:

- how large should be the section of the tongue;

- how deep it should be driven;

- what additional steps need to be taken to make everything sound and reliable.

When the element is just hammered into the ground, the load is identical on both sides.

But during the development of the pit, the balance disappears, the intensity of pressure from the inside decreases. This moment must be taken into account in the calculations. Therefore, one cannot do without the involvement of complex methods based on the theory of the limiting equilibrium of soils. And also the graphic-analytical method of elastic line can be applied.

Such methods are quite accessible to professionals, but you shouldn't deal with them on your own, you won't have to. The arrangement is calculated by various methods depending on the anchor or non-anchor design of the walls. In the first version, the turning point is found at the bottom of the pit, and in the second - where the anchor brace is placed. The immersion depth varies depending on:

- waterproof cushion;

- soil density;

- chemical and mechanical composition of the soil.

Correct calculations include determining:

- parameters of position stability;

- strength of materials;

- durability of the pits bottoms;

- the depth of driving the sheet piles;

- design resistance.

Additionally use:

- design moments of holding and overturning loads;

- calculation coefficients for viscous soil;

- reliability indices;

- working conditions coefficients.

Soil immersion methods

Correct installation can be carried out by driving in the tongue and groove. This is a very affordable and time-saving method. However, it is not always possible to use this approach. Hammers generate a lot of noise and vibration. This negatively affects neighboring structures and may even violate the law on silence, sanitary rules.

When hitting, the ground becomes denser. That is why deep immersion of the sheet pile without preliminary leader drilling will be impossible. Most often, driving is done with diesel hammers. They are equipped with petal headbands. Even before starting work of the installation in the ground, holes must be made to provide a hook with hooks. Otherwise, slinging and centering will not be possible.

Driving itself is carried out by impact and explosive energy. The impact is determined by the mass of the striker. The explosive effect is due to the detonation of the fuel. Diesel hammers, even of the best examples, wear very intensely. It is more expensive to nail down a sheet pile than a pile, and the technical control over the process must be very strict.

Vibration immersion is an alternative. It is mainly used when working on moderately dense ground. This method eliminates the deformation of the sheet pile (subject to technical standards). The divers operate at low, medium or high frequency. The first type is most widely used in densely built-up areas.

Vibration is bad because the soil will become less dense next to the walls of the sheet pile. You can drive the product to the required depth without any problems. The rate of sinking is determined by the difference between the force of resistance and the power of the vibration factor. To overcome very strong resistance, the soil is often deliberately washed out.

For this, the metal structure is supplemented with channels through which water can be supplied.

Vibrating machines in our country began to be used for the introduction of sheet piles back in the 1950s. Then this became possible thanks to advanced engineering developments and a high level of technical sciences. Since then, the level of machines has grown significantly. Along with the increase in productivity, attention was paid, of course, to the safety for the soil itself and the reduction of vibration and noise load on the external environment. Vibration immersion of the sheet piles helps to combat the formation of sinkholes, longitudinal deflection of long buildings.

Thanks to it, the settlement of flexible buildings on soft ground is minimized. Despite the impacts, with a well-chosen operating mode, there is usually no need to pre-calculate or instrumentally evaluate vibrations in soils. At the same time, it is critically important to maintain the distances to buildings or to underground utilities.

If these distances cannot be maintained according to the standard, a study of the effects of vibration must be carried out. It is normally accompanied by geotechnical monitoring of the state of the soil.

The sooner submerged elements are introduced, the less the total negative impact on the external natural environment. It is especially important to work quickly near protected natural areas and cultural monuments. In this case, even highly sensitive biocenoses or emergency buildings will not experience tangible harm. In cramped conditions, it is impossible to replace the crane with a headstock. This is only possible on large construction sites. It is very important to reduce the initial level of fluctuations. It is also worth noting that modern vibratory drivers are increasingly working with the help of remote control.

In densely built areas, static indentation is often recommended. This option for using tongue-and-groove piles is the youngest, but it has already proven itself well. Vibration is completely absent. There is no noise either. However, the disadvantage is the insufficient productivity of work.

True, this disadvantage is compensated by the lack of the need for large-sized equipment. The indentation can be combined with hydraulic fracturing of the wells. But this is not always achievable, but only on condition that the soil resistance is relatively small. The indentation allows you to overcome the resistance of even very hard ground.

In many cases, you can completely do without drilling wells.

Pressing plants are widely used in industrialized countries. Thanks to them, the introduction of sheet piles is possible even near densely populated neighborhoods, subway or railway lines. The immersion of structures by this method can be flexibly adjusted. From an environmental point of view, the indentation technique is the most gentle. And it should also be emphasized that this option guarantees increased reliability of the installed sheet piles.

Extraction features

The need to remove sheet piles is mainly associated with their use at other sites. Vibratory submersibles of the resonance type help to remove the pit fences.... They are suspended on a crane hook. The technique is designed so that the amplitude and frequency of the oscillations can be easily corrected. This approach makes it possible to almost eliminate the negative effects of vibrations.

The dowels are removed first where they are pulled out with the least resistance. Only then do they move on to more complex areas. They start with the preparation of the site for the installation of the truck crane. The sites for the accumulation of the removed parts are also prepared in advance. Then the equipment is mounted and adjusted.

Using a hydraulic clamp, the vibrator is fixed on one edge of the tongue. When turning on the device, pull the hook up at the same time. This is usually enough to pull the tongue out. But if any shortcomings are found, they must be eliminated with the help of metalworking. To prevent the crane boom from suffering from vibration, shock absorbers are used. Hook lifting speed of more than 5 m per minute is not allowed.

The lower springs of the dumper are compressed first. This is ensured by a slight tension on the hoisting rope. When the diver is turned on, it vibrates for exactly 60 seconds without any increase in lifting force. As a result, the elastic force will tear the tongue off the ground. A force equal to twice the weight of the pile and the driver together is required. The removed part is unlocked, placed in the storage space and freed from the vibrator.

The comment was sent successfully.