All about diesel generator repair

Simple repair of diesel generators is within the power of anyone who is familiar with the device of a car or motorcycle. The article presents possible malfunctions of diesel power plants and methods for their elimination, as well as advice on their prevention.

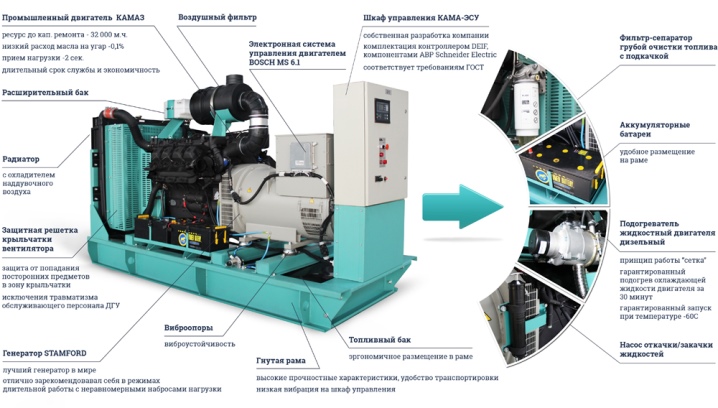

Device

The main task of the portable power plant - conversion of mechanical energy into electrical energy.

Devices operating on diesel fuel are distinguished by high reliability of operation and low cost of operation.

But the design of such generators is more complicated than gasoline generators, and they require better service. Therefore, in order to carry out repairs, it is imperative to know their structure.

A diesel generator, like a gasoline generator, consists of 4 main parts:

- internal combustion engine (aka internal combustion engine);

- an alternating (or direct) current electric generator;

- a coupling connecting the shafts of the internal combustion engine and the generator;

- control system.

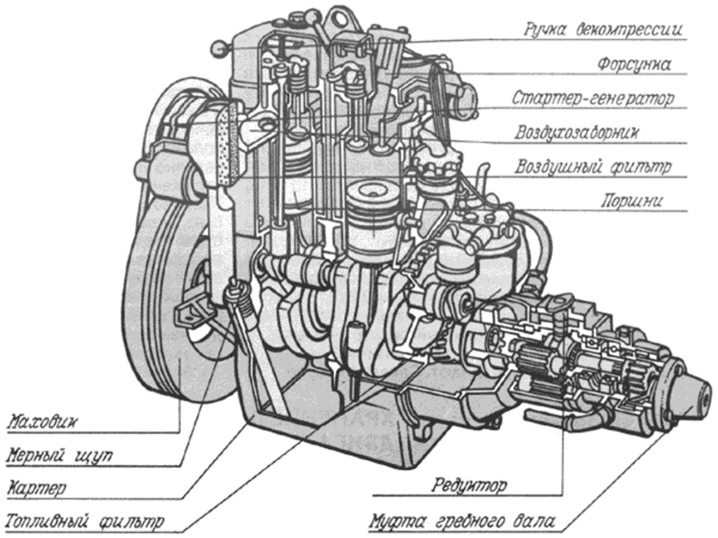

The engine has the following systems:

- food;

- gas distribution;

- lubricants;

- electrical equipment;

- cooling and others.

Wherein a diesel engine, unlike a gasoline engine, does not have an ignition system. Spark plugs are only needed for starting.

The generator consists of 3 main parts:

- stationary stator;

- rotating rotor;

- sliding contact (some models may not have it).

In the event of a breakdown, it is important to correctly identify the problem.

Sometimes the same externally failures can be caused by different reasons. And if the repair cannot be done on your own, then qualified specialists will come to the rescue.

If you decide to fix the damage yourself, do not forget about safety precautions.

- Work in a well-ventilated area or outdoors. Be careful with gasoline vapors. Avoid sparks.

- When repairing an electrical system, pay particular attention to capacitors. Even after the installation is turned off, a very large charge may remain on them. Before work, they need to be discharged, to do this, short-circuit their contacts. It is recommended to do this through resistance.

- Do not allow oil and gasoline to come into contact with rubber and plastic parts.

- Prepare enough rags. When working with an internal combustion engine, your hands will inevitably get dirty, and dirt on electrical wires and contacts is undesirable.

- Some fasteners may have sour from time to time. To separate them, you need to moisten them with kerosene.

- The housing must be grounded.

Possible malfunctions and their elimination

Determine what caused the failures before repairing. It is possible that the problem is due to misuse of the generator. Always start your renovation from simple to complex.

ICE breakdowns

First, consider the malfunctions of the internal combustion engine. Checking the condition of the fuel system should be started from the gas tank to the injectors:

- the system must be sealed, air and fuel drips are not allowed;

- make sure that the fuel comes from the tank to the coarse and fine filters;

- check the booster pump;

- make sure that fuel is supplied to the high pressure fuel pump (injection pump);

- check the correct operation of the injectors.

To check for air, unscrew the supply tubes and pump the fuel with the hand pump. There should be no air bubbles in the liquid stream. Inspect the nozzles. If there is carbon build-up, try removing it with rubbing alcohol.

If this does not work, the nozzles must be replaced.The flow of fuel from them should be smooth, in the form of small droplets. If this is not the case, the nozzles must be replaced (this is the part that is located inside the combustion chamber).

Starter malfunctions include:

- poor electrical contacts - they must be clean and shiny;

- malfunctions of the retractor relay - it must be replaced;

- burnout of the winding - the starter must be changed.

If the engine stalls, take the following actions.

- Check the control system - one of the sensors could be broken there. Sometimes a faulty electronics is checked by a tester, so to check it, it is better to replace it with a known working one.

- Dirt can accumulate in the tank and fuel lines, especially during the cold season. The blockages must be removed.

To clean strong rust inside the tank, remove it and pick up a handful of small stones. Next, fill in some oil or solvent. Shake the tank vigorously so that the stones have removed all dirt. After that, remove this substance and rinse the inner cavity.

If there is a high oil consumption, you need change piston rings.

To do this, it is better to contact the service, since you need to completely disassemble the internal combustion engine. Loud knocking occurs when there are problems with bearings, bushings and other moving parts.

If the color of the exhaust gases has changed, the probable cause is the ingress of coolant into the combustion chambers. To fix, do the following:

- check the injection pump and injectors;

- replace piston rings;

- check the cylinder head gaskets and the cooling system.

With an unstable engine speed you need to inspect the injection pump and the power system. Do the same if after a while the engine stops by itself or the color of the exhaust gases turns black. The normal exhaust color is clear. It sets in after a while when the condensate evaporates. If there is too much smoke, you need to inspect the piston group and check the compression.

If there is a lack of power, then, most likely, the matter is in the power supply system. Possible reasons:

- the timing of fuel injection is incorrect;

- clogged filters;

- malfunctions of the injection pump;

- the gap in the valves is lost or they are burnt out;

- injectors are faulty;

- a foreign object has entered the exhaust system.

Inspect the muffler periodically. Due to the high temperature of the exhaust gases, it can burn out or become cracked.

And if a two-stroke diesel engine (sometimes there are such), then it can get clogged with unburned oil, especially when operating at low power.

If the engine overheats, check the radiator of the cooling system. Over time, it becomes clogged with deposits, therefore, it must be cleaned or replaced.

Electrical faults

If the generator does not supply the required voltage or it "jumps", inspect the sliding contact. Over time, graphite brushes wear off, they must be replaced with similar ones.

Oiling the brushes occurs when antifreeze or oil gets on them. For repair, they must be removed, degreased and reinstalled. If this happens frequently, check the tightness of all pipes. Over time, the springs that press the brushes against the rotor also weaken. They need to be changed or tightened.

The rotor must be firmly seated in the bearings and rotate without wobbling. If there is, the repair must be started immediately, otherwise the bearing will break the seat. Then you have to change the side cover.

If there was a short circuit of the winding, you need to rewind it. This can only be done in a service center, since the procedure is very complicated. The integrity of the windings is checked with a multimeter. The resistance of all phases should be approximately the same.

Pay attention to spark plugs... They need to be periodically cleaned of carbon deposits, just like the nozzles. Or change. A symptom of a malfunction - the engine does not start the first time with a working power system.Sometimes the control system also gets lost, then you need to reset the settings. In expensive models, a computer is connected to the generator, with the help of which a reset is performed.

Still, a malfunction is easier to prevent than to fix. Now we will talk about preventing breakdowns.

Preventive measures

For normal operation of the generator, treat it with care and follow a few simple rules.

- Follow the instruction manual carefully.

- Check the fuel for the weather. In the cold season, winter fuel should be used. In winter, a more fluid lubricant is required, since the oil thickens in the cold.

- Make sure that the generator amperage matches the total power of the consumers. If the energy consumption exceeds the generated one, the generator will not work correctly.

- The battery must be replaced every 3-5 years. During this time, the capacity of even the highest quality battery decreases, so it does not deliver the current of the required strength. This leads to startup problems.

- Go through scheduled maintenance after a certain time of work. Usually it is 250 thousand engine hours.

- Remember to periodically clean the fuel and air filters, drain the sediment tanks, and check the cleanliness and oil level.

- Check the integrity of all bolted connections occasionally. They can unwind from vibration.

- Keep the device clean. Disassemble it periodically for cleaning and lubrication. Pay particular attention to the fins and the heatsink.

- Avoid operating the unit in extremely dusty air and high humidity. This shortens its service life.

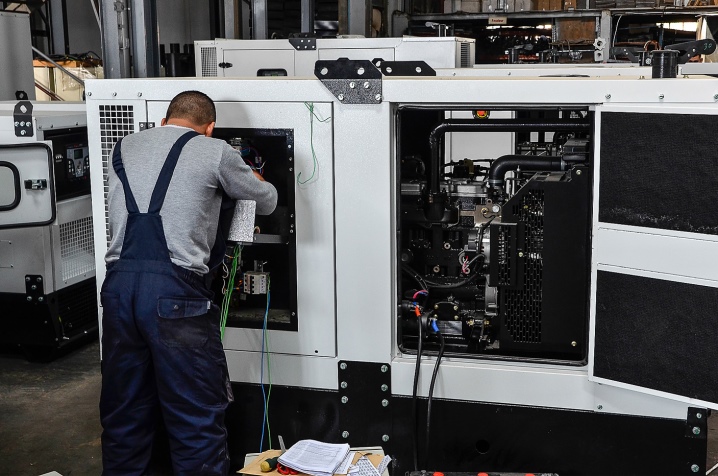

- It is almost impossible to carry out major repairs on your own. Trust it only to qualified specialists who have professional equipment.

For repairing a diesel generator, see below.

The comment was sent successfully.